In a factory put together where flooring is actually subject to a great deal of use and tear, option of the right flooring is essential, since it's a system of the initial investment and it is often spread throughout a large region. You need to most certainly look into an epoxy flooring coating if you are contemplating changing the walking surfaces of yours.

Images about 2 Part Epoxy Garage Floor Coating

This's exactly why, with regards to renovating you floors, you may as well install epoxy flooring. Thus to be precise, epoxy resins have fairly limitless applications & advantages. As a result, in case you are into redefining garage or warehouse flooring, try epoxy coating for traditional pro appeal to the floor. Hence, you are going to need to strip a polyurethane or perhaps latex floor before using epoxy.

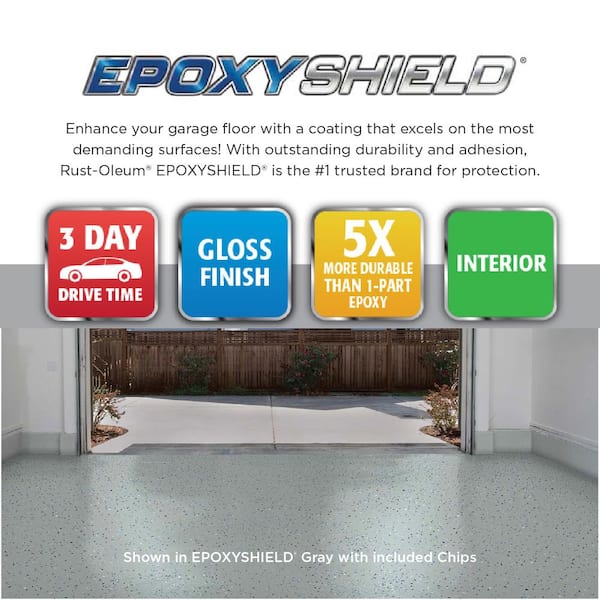

Rust-Oleum EpoxyShield 90 oz. Clear High-Gloss 2-Part Epoxy

The epoxy flooring coatings are usually made use of over concrete floors to supply best binding results and visually attractive surfaces. Epoxy floors can tolerate high pressure and weight. Probably the most widely used sort of epoxy floors for the place is actually the water based version as it likely the easiest of them to use as it's made up both of the primer and also topcoat and is certainly ideal for making use of in garage areas.

Best Garage Floor Coating of 2022 – This Old House

/cdn.vox-cdn.com/uploads/chorus_asset/file/22308892/1120_FEA_Idea_House_Fairfield_Farmhouse_08142020NR_0078_v3.jpg)

They're created to triumph over every obstacle ranging from probably the toughest stains which can be hard to eliminate and to endure the toughest environmental circumstances. You merely clean and prep your floor and then start applying the new epoxy flooring surface with a roller. This will make the floor look neater as well as cleaner. The surface is drinking water and stain resistant.

How to Apply Epoxy Coating to a Garage Floor

:max_bytes(150000):strip_icc()/clean-garage-178594527-ed57fd7843ba42f59bb637cf7cf5d47d.jpg)

Rust-Oleum EpoxyShield 2 Gal. Gray Garage Floor Epoxy 261845

Rust-Oleum EpoxyShield 2-part Gray Gloss Concrete and Garage Floor

Epoxy Garage Floors Mesa, AZ u2014 Clouse Legacy Coatings

EpoxyShield Garage Floor Coating Rust-Oleum

Rust-Oleum High performance 2-part Gray Gloss Concrete and Garage

The Benefits of Epoxy Garage Floor Coatings All Garage Floors

Rust-Oleum EpoxyShield 90 oz. Clear High-Gloss 2-Part Epoxy

What are the Best Clear Coats for Garage Floor Coatings? All

How Much Does It Cost To Epoxy Garage Floor?

Amazon.com: Rust-Oleum 261846 EPOXYSHIELD Garage Floor Coating

Related Posts:

- Epoxy Floor Squeegee

- Novolac Epoxy Floor Coating

- Valspar Garage Floor Epoxy Colors

- Floor Preparation For Epoxy

- Mortar Epoxy Coatings For Floors

- Top Coat For Epoxy Garage Floor

- Epoxy Flooring Experts

- Epoxy Metallic Garage Floor

- Garage Floor Epoxy Canada

- Quikrete Epoxy Flooring

Transform Your Garage with a 2 Part Epoxy Garage Floor Coating

Introduction:

Your garage floor takes a beating every day – from heavy vehicles, oil spills, dirt, and constant foot traffic. If you’re tired of looking at a dull, stained, and cracked floor, it’s time to consider a 2 part epoxy garage floor coating. This innovative solution not only enhances the appearance of your garage but also provides long-lasting durability and protection. In this article, we will explore the benefits, application process, FAQs, and more about this transformative flooring option.

Benefits of a 2 Part Epoxy Garage Floor Coating:

1. Durability: One of the primary reasons homeowners choose a 2 part epoxy garage floor coating is its exceptional durability. The epoxy creates a tough surface that can withstand heavy loads without cracking or chipping. It is resistant to chemicals, such as gasoline and oil spills, making it ideal for automotive enthusiasts or those who frequently work in their garages.

2. Enhanced Appearance: Say goodbye to the dull and uninspiring look of your garage floor! With a 2 part epoxy garage floor coating, you can instantly transform your space into a visually appealing area. The glossy finish adds depth and shine to your floor, making it an attractive feature of your garage.

3. Easy Maintenance: Cleaning becomes effortless with an epoxy-coated garage floor. The smooth surface prevents dirt and stains from penetrating deeply, allowing for quick and easy cleaning with just soap and water. Additionally, the high chemical resistance ensures that any spills or leaks can be wiped away without leaving stubborn marks.

4. Longevity: Unlike traditional concrete floors that are prone to cracks and deterioration over time, an epoxy coating provides long-lasting protection. When properly installed and maintained, it can last for many years without showing signs of wear or damage.

Application Process:

Applying a 2 part epoxy garage floor coating requires careful preparation and attention to detail. Here is a step-by-step guide to help you achieve a professional-looking finish:

1. Surface Preparation: Proper surface preparation is crucial for the success of your epoxy coating. Start by thoroughly cleaning the floor to remove any dirt, grease, or existing coatings. Use a degreaser and a stiff brush to scrub away stubborn stains. Rinse the floor with water and allow it to dry completely before proceeding.

2. Repairing Cracks and Imperfections: Inspect the floor for any cracks or imperfections. Fill these areas with an epoxy-based patching compound and smooth it out with a trowel. Allow the compound to cure according to the manufacturer’s instructions.

3. Etching the Floor: To ensure proper adhesion, etch the surface of the concrete using an acid etching solution or mechanical methods such as grinding or shot blasting. This step opens up the pores of the concrete, allowing the epoxy to penetrate and bond effectively.

4. Applying Primer: Apply a primer coat using a roller or brush. The primer helps create a strong bond between the epoxy and the concrete surface, ensuring better adhesion and durability.

5. Mixing and Applying Epoxy: Follow the manufacturer’s instructions to mix the two components of the epoxy coating thoroughly. Pour the mixture onto the floor in small sections and spread it evenly using a roller or squeegee. Work quickly but carefully to avoid bubbles or uneven distribution.

6. Adding Decorative Flakes (Optional): For added aesthetic appeal, you can sprinkle decorative flakes onto the wet epoxy surface. These flakes come in a variety of colors and sizes, allowing you to customize the look of your garage floor. Sprinkle the flakes evenly over the epoxy and allow them to fully dry before moving on to the next step.

7. Applying a Topcoat: Once the epoxy is fully cured, apply a clear topcoat for added protection and shine. Use a roller or brush to apply the topcoat in thin, even layers. Allow each layer to dry completely before applying the next one.

8. Allowing for Curing Time: After completing the application process, it is crucial to allow the epoxy coating to cure fully before using the garage floor. This can take anywhere from 24 to 72 hours, depending on the manufacturer’s instructions and environmental conditions.

With these simple steps, you can transform your garage floor into a beautiful and durable space that you can be proud of. Say goodbye to dull and uninspiring surfaces and hello to a visually appealing garage that reflects your style and personality. Remember to always follow the manufacturer’s instructions and take necessary safety precautions when working with epoxy coatings. Some additional tips for success when applying epoxy coatings to your garage floor include:

– Make sure the temperature and humidity conditions are within the manufacturer’s recommended range for application. Extreme temperatures can affect the curing process and adhesion of the epoxy.

– Use a high-quality epoxy coating specifically designed for garage floors. These coatings are more durable and resistant to chemicals, stains, and wear.

– Consider using a non-slip additive in the topcoat for added safety, especially if your garage floor gets wet frequently.

– Take your time during the application process to ensure proper coverage and an even finish. Rushing can lead to mistakes and imperfections.

– Keep in mind that epoxy coatings require regular maintenance to preserve their appearance and durability. This may include periodic reapplication of topcoats or touch-ups in high traffic areas.

– Avoid driving vehicles or placing heavy objects on the newly coated floor until it has fully cured. Premature use can damage the coating and affect its longevity.

By following these additional tips, you can enhance the success and longevity of your epoxy-coated garage floor.