Epoxy floors have numerous benefits; they could be worn in tough manufacturing settings, they're waterproof and are resistant to chemical and acids. The significance of an epoxy floor coating is certainly realized. All you require is a spray gun and you'll be done in a few hours. Epoxy flooring stops stains and helps hold a good concrete surface.

Images about Anti Static Epoxy Floor Coating

One other reason this- Positive Many Meanings- epoxy flooring is on a very short list for designers is that it could be easily personalized. Epoxy floorings are floorings applied with levels of tough, long lasting coating known as epoxy. The prroperty owner also can get a clear epoxy covering poured over ready hardwood floors. It is imperative that the epoxy is combined correctly to ensure correct curing.

Static Control Epoxy Flooring u0026 CRU Coatings Industrial Concrete

You can find three major kinds of epoxy for floor surfaces. Not only are these sorts of floorings mechanically powerful but they are in addition resistant to chemical based components once they start to be solid as well as being extremely adhesive throughout the stage whenever they modified from liquid to the solid form you see on most floors today.

6700C Premium ESD Static Conductive Anti-Static Floor Paint 9 Colors ANSI/ESD S20.20-2014

You will need to get all of the measurements and figure merely a bit larger than you may possibly need which means you do not run short. They are great for restaurants along with other food processing business organizations, and therefore are likewise widely used in manufacturing settings. Use a covering of epoxy on the area where by there was the stain.

Antistatic Epoxy Floor Coatings at Rs 50/square feet East Of

Anti-Static Flooring, Anti-Static Resin Flooring – Impact Flooring

Anti Static Flooring, Epoxy S20.20 certified USA Installation

HB-97.2 ESD Conductive Epoxy Primer ANSI S20.20-2014 In 7 colors

How Anti-static epoxy flooring can be applied? – Neocrete

China Top Five-Maydos Self Leveling Anti Static Epoxy Floor Coatings

Anti Static Epoxy Flooring epoxy floor coating anti static

ESD Epoxy Floor Paint

SGA solutions epoxy flooring self leveling sports

EPOXY ANTISTATIC PRIMER

Antistatic epoxy floor coating used in facilities with antistatic

Related Posts:

- Epoxy Floor Hardener

- Dunn Edwards Epoxy Floor Paint

- Gladiator Epoxy Flooring

- Is Epoxy Flooring Safe

- Epoxy Resin Floor Paint

- How To Epoxy Your Garage Floor

- How To Do Epoxy Flooring In Basement

- Outdoor Epoxy Resin Flooring

- Concrete Epoxy Floor Preparation

- Metallic Epoxy Floor Pros And Cons

Title: The Benefits of Anti-Static Epoxy Floor Coating for Industrial and Commercial Spaces

Introduction:

In today’s technologically advanced world, the importance of protecting sensitive electronic equipment from static electricity cannot be overstated. This is where anti-static epoxy floor coatings come into play. These specialized coatings are designed to dissipate static charges and provide a safe environment for both personnel and delicate equipment. In this article, we will delve into the detailed benefits, applications, and frequently asked questions surrounding anti-static epoxy floor coatings.

I. Understanding Anti-Static Epoxy Floor Coating:

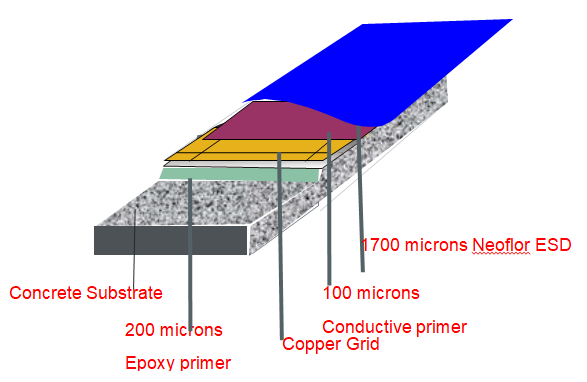

Anti-static epoxy floor coatings are a specially formulated blend of epoxy resins infused with conductive materials, such as carbon fibers or metallic particles. This combination creates a conductive pathway that effectively dissipates electrical charges, preventing static buildup on the surface of the flooring.

1. How does anti-static epoxy floor coating work?

Anti-static epoxy floor coatings work by actively grounding static electricity to ensure a neutral charge throughout the flooring surface. The conductive elements within the coating allow any electrical charge to flow safely through the coating and into the ground, eliminating the potential for static discharge.

2. What are the advantages of using anti-static epoxy floor coating?

The advantages of anti-static epoxy floor coatings are numerous:

– Electrostatic discharge protection: By effectively grounding electrical charges, these coatings prevent electrostatic discharges that can damage sensitive electronic components.

– Safety enhancement: Anti-static coatings reduce the risk of personnel experiencing electric shocks when handling electronic devices or working in proximity to them.

– Chemical resistance: Epoxy floor coatings are highly resistant to chemicals, ensuring durability even in harsh industrial environments.

– Seamless surface: The seamless nature of epoxy flooring eliminates cracks and joints where dirt, bacteria, or contaminants could accumulate.

– Aesthetic appeal: These coatings can be customized with various colors and designs to enhance the overall aesthetics of a space.

II. Applications of Anti-Static Epoxy Floor Coating:

Anti-static epoxy floor coatings find wide-ranging applications in industrial, commercial, and healthcare settings. Let’s explore some of the most common uses:

1. Electronics manufacturing facilities:

In electronics manufacturing facilities, where sensitive electronic components are produced or repaired, anti-static epoxy floor coatings are essential. These coatings protect against static discharge that could damage delicate equipment and ensure a safe working environment for technicians.

2. Data centers and server rooms:

Data centers and server rooms house critical IT infrastructure that can be severely impacted by static electricity. Anti-static epoxy floor coatings provide a controlled environment by reducing static charges, minimizing the risk of data loss or equipment failure.

3. Laboratories and cleanrooms:

In laboratories and cleanrooms, where precision instruments and sensitive experiments are conducted, anti-static flooring is crucial to prevent electrostatic discharge that may interfere with research outcomes or damage expensive equipment.

4. Automotive manufacturing plants:

Automotive manufacturing plants often deal with flammable materials, making static electricity a significant safety concern. Anti-static epoxy floor coatings ensure a safe working environment by grounding electrical charges and preventing sparks that could ignite flammable substances.

III. Frequently Asked Questions (FAQs):

1. How long does an anti-static epoxy floor coating last?

When properly installed and maintained, an anti-static epoxy floor coating can last between 10 to 15 years or longer, depending on the specific conditions of the environment it is exposed to.

2. Is an anti-static epoxy floor coating easy to clean?

Yes, one of the advantages of anti-static epoxy flooring is its ease of Cleaning. The seamless surface of the coating makes it easy to sweep or mop, and its chemical resistance allows for the use of cleaning agents without damaging the floor.

3. Can anti-static epoxy floor coatings be installed over existing floors?

Yes, in many cases, anti-static epoxy floor coatings can be applied over existing floors, such as concrete or tile. However, it is important to assess the condition and suitability of the existing floor before installation to ensure proper adhesion and performance of the coating.

4. Are there any special maintenance requirements for anti-static epoxy floor coatings?

While anti-static epoxy floor coatings are durable and low-maintenance, regular cleaning and maintenance are still necessary to prolong their lifespan and ensure optimal performance. This may include routine sweeping or mopping, avoiding harsh chemicals or abrasive cleaners, and addressing any spills or stains promptly.

5. Can anti-static epoxy floor coatings be used in outdoor settings?

No, anti-static epoxy floor coatings are typically designed for indoor use only. Outdoor exposure to UV radiation and fluctuating temperatures can degrade the coating and compromise its performance. It is important to consult with a professional to determine the most suitable flooring option for outdoor environments.