For the entryway, bath room, or maybe kitchen there are tiles that can be created of epoxy. Whether you want to create the ideal workplace or maybe a high home decor, you are going to be happy with the results. An epoxy floors coating may be installed easily, with little down time. The resin as well as hardener are actually blended together to chemically respond.

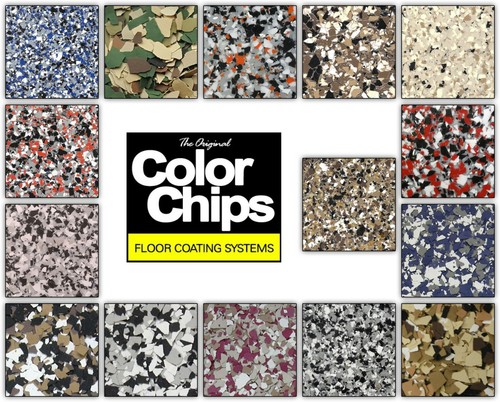

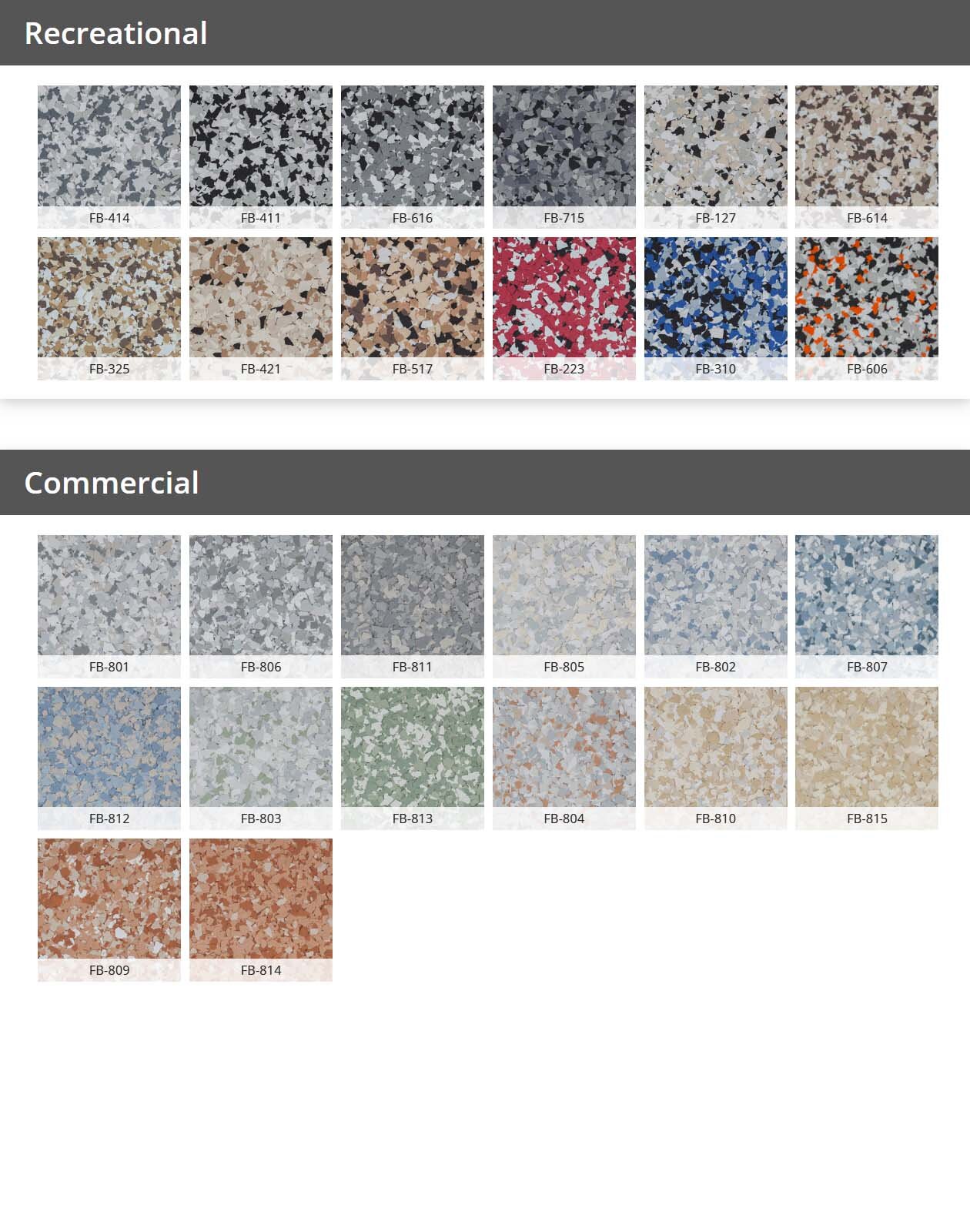

Images about Color Flakes Epoxy Floors

Epoxy floors are available in all types of styles and varieties. On the flip side, in case you have a brand new slab, wait for no less than a month for the flooring to be completely dry just before epoxy program. Even the epoxy paints can be granted desired textures too. You will find a whole lot of advantages in employing epoxy as being a floor coating. The price of an epoxy flooring is much like that of other flooring types.

Epoxy Floor Color Flakes

Epoxy flooring surfaces are not hard to clean and are shockingly resistant to bacteria. In past days, epoxies flooring coatings happened to be restricted to merchandise retailers, but with the advent of technology, they have grown to be a trend for flooring really needs in industries, hospitals, garages, warehouses, factories, showrooms, as well as federal government facilities brightening up the floor surfaces.

FLAKE Polymer ColorFlakesTM u2013 Torginol, Inc.

Poly urea pains generally cost up to 4 times the amount of epoxy flooring as well as homeowners or perhaps business people do not see any advantages of coming from the expanded price. The fact is that this only comes in one color, tan, though it can be utilized often by itself or with other epoxy floorings.

Florescent (Black Light) Flakes for Epoxy, Polyaspartic, Urethane Coatings

Mica Metallic Flakes for Epoxy, Polyaspartic Floor Coatings

Estes Color Flakes Industryu0027s Best Vinyl Paint Chips for

Chicagoland Flake Epoxy Flooring Professionals – Flake Epoxy Experts

Original Color Chips – 1/4″ Garage Floor Epoxy Flakes, 28 Blended Color Options eBay

Epoxy Flake Floors Miami Specialty Garage Floors

Garage Floor Epoxy Colors, Charts, Datasheets u0026 Directions

Bright Blue Flake Epoxy Garage Installation View Photos of Project

Marble Flake Epoxy

Epoxy Flooring Atlanta u0026 Metro Atlanta u2014 Grindkings Flooring

Epoxy Color Chart – Epoxy Floor Paint Color Chart

Related Posts:

- Are Epoxy Floors Slippery

- Tennant Epoxy Flooring

- Can You Paint Over Epoxy Garage Floor

- Quikrete Epoxy Flooring

- Exterior Epoxy Flooring

- Epoxy Floor Repair Products

- 100 Solids Epoxy Garage Floor Paint

- Self Leveling Epoxy Floor Patch

- What Is Epoxy Flooring Systems

- Hardwood Floor Epoxy Filler

Color Flakes Epoxy Floors: A Beautiful and Durable Flooring Option

When it comes to flooring options, there are endless possibilities to choose from. However, if you are looking for a flooring solution that combines both aesthetics and durability, color flakes epoxy floors might be the perfect choice for you. These unique and versatile floors offer a multitude of benefits and can transform any space into a visually stunning masterpiece. In this article, we will delve into the world of color flakes epoxy floors, exploring their features, benefits, installation process, maintenance requirements, and frequently asked questions.

1. Introduction to Color Flakes Epoxy Floors

Color flakes epoxy floors are a type of seamless flooring system that combines epoxy resin with colored vinyl chips or flakes. These flakes are available in various sizes, colors, and blends, allowing you to create a customized look that suits your style and preferences. The epoxy resin acts as a binder that holds the flakes together and provides a smooth and durable surface.

2. The Benefits of Color Flakes Epoxy Floors

2.1 Enhanced Aesthetics: One of the primary reasons why color flakes epoxy floors have gained immense popularity is their ability to enhance the visual appeal of any space. The vibrant colors and endless design possibilities make these floors a favorite among homeowners, business owners, and interior designers alike.

2.2 Durability: Color flakes epoxy floors are known for their exceptional durability. The combination of epoxy resin and vinyl flakes creates a strong and resilient surface that can withstand heavy foot traffic, impacts, abrasions, and chemical spills.

2.3 Slip-Resistance: Safety is always a top priority when it comes to flooring choices. Color flakes epoxy floors offer excellent slip-resistance properties due to the textured surface created by the vinyl flakes embedded in the epoxy resin.

2.4 Easy Maintenance: Unlike many other flooring options, color flakes epoxy floors are incredibly easy to clean and maintain. They are resistant to stains, dust, and dirt, making them an ideal choice for high-traffic areas or spaces where cleanliness is of utmost importance.

2.5 Cost-Effective: In the long run, color flakes epoxy floors can prove to be a cost-effective flooring solution. Their durability eliminates the need for frequent repairs or replacements, saving you both time and money.

3. The Installation Process of Color Flakes Epoxy Floors

The installation process of color flakes epoxy floors involves several steps that require professional expertise and specialized equipment. Here is a brief overview of the installation process:

3.1 Surface Preparation: The first step in installing color flakes epoxy floors is preparing the existing surface. This includes cleaning, repairing any damages or cracks, and ensuring it is free from any contaminants that may hinder the adhesion of the epoxy resin.

3.2 Primer Application: A primer is then applied to the prepared surface to promote better adhesion and create a strong bond between the existing floor and the epoxy resin.

3.3 Epoxy Resin Application: Once the primer has cured, multiple layers of epoxy resin are applied using a roller or squeegee. The thickness and number of coats depend on your specific requirements and the type of traffic your floor will endure.

3.4 Flake Broadcast: As soon as the final layer of epoxy resin is applied, colored vinyl flakes are broadcasted evenly onto the wet surface. The amount of flakes used can vary depending on your desired look.

3.5 Topcoat Application: To seal and protect the colored flakes and provide added durability, A topcoat is applied. This topcoat can be either a clear epoxy or a polyurethane coating. It enhances the longevity of the floor and provides additional resistance to abrasion, chemicals, and UV rays.

3.6 Curing and Drying: After the topcoat is applied, the floor needs to cure and dry for a specific period of time. This allows the epoxy resin to fully harden and create a strong bond with the underlying layers.

3.7 Final Inspection: Once the floor is fully cured, a final inspection is conducted to ensure that it meets all quality standards. Any necessary touch-ups or adjustments are made at this stage.

Overall, the installation process of color flakes epoxy floors requires careful preparation, precise application techniques, and sufficient curing time to achieve a durable and visually appealing result. It is highly recommended to hire professionals with experience in installing epoxy floors to ensure a successful installation. Color flakes epoxy floors offer several advantages, including easy maintenance and durability. They are resistant to stains, dust, and dirt, making them suitable for high-traffic areas and spaces where cleanliness is crucial. Additionally, they can be a cost-effective flooring solution as they eliminate the need for frequent repairs or replacements, saving both time and money.

The installation process of color flakes epoxy floors involves several steps that require professional expertise and specialized equipment. The first step is surface preparation, which includes cleaning, repairing any damages or cracks, and ensuring the surface is free from contaminants that may hinder adhesion. A primer is then applied to promote better adhesion and create a strong bond between the existing floor and the epoxy resin.

Multiple layers of epoxy resin are then applied using a roller or squeegee, with the thickness and number of coats depending on specific requirements and the type of traffic the floor will endure. Once the final layer of epoxy resin is applied, colored vinyl flakes are evenly broadcasted onto the wet surface. A topcoat is then applied to seal and protect the colored flakes, providing added durability. This topcoat can be either a clear epoxy or a polyurethane coating.

After the topcoat is applied, the floor needs to cure and dry for a specific period of time to allow the epoxy resin to fully harden and create a strong bond with the underlying layers. A final inspection is then conducted to ensure that the floor meets all quality standards, with any necessary touch-ups or adjustments made at this stage.

Overall, careful preparation, precise application techniques, and sufficient curing time are essential for achieving a durable and visually appealing result when installing color flakes epoxy floors. It is highly recommended to hire professionals with experience in installing epoxy floors to ensure a successful installation.