There are a range of diverse techniques you are able to use to concrete flooring to produce beautiful decorative floors made for both the office of yours and the home of yours. In the event that you want to drive a tank over it, once poured, concrete can take it. With acid stained concrete flooring, you have options readily available to satisfy the design needs of yours.

Images about Composite Steel And Concrete Floor Construction

In order to change the color of the floor, buyers could request shake-on color hardeners or even penetrating synthetic stains and dyes to alter their grey colored concrete to any kind of number of colors. Recently that has changed as more and more people are realizing that a polished concrete floor really looks great. Polished concrete flooring looks far more slippery than it is.

Composite construction – SteelConstruction.info

Thus concrete flooring has grown to be the original choice of not the household but even the business and business owner. In winter, it gets more dry and retains the warmth of the sunshine. The appeal would be that with regards to polished concrete flooring, one could be sure the original look can be re instated. The diamond concrete polishing operation is relatively simple.

Specifying and achieving a level composite steel floor

Concrete Composite Floors u2013 Construction Details u2013 Structural Detailer

Design of composite steel deck floors for fire – SteelConstruction

What is Composite Floor Decking u0026 How Does it Work?

Steel Decking for Concrete Floors, Ecospan, Get More for Less

Types of Floor Systems for Steel Framed Buildings – Structville

STRUCTURE magazine A Practical Design for Thin Composite Steel

Composite beam Article about composite beam by The Free Dictionary

STEEL CONCRETE COMPOSITE BEAMS – The Constructor

Design of Composite Slab with Profile Metal Deck – Structville

Floor systems – SteelConstruction.info

Materials Free Full-Text Behavior of a Two-Way Lightweight

Related Posts:

- How To Insulate An Existing Concrete Floor

- Decorative Concrete Floor Painting Ideas

- Concrete Floor Beams Sizes

- How To Seal Concrete Floor Before Carpeting

- How To Paint Old Concrete Floor

- How To Clean Concrete Floor Before Epoxy

- Concrete Floor Loft

- Scored And Stained Concrete Floors

- ding Paint Off Concrete Floor

- Concrete Floor Upstairs

Introduction to Composite Steel and Concrete Floor Construction

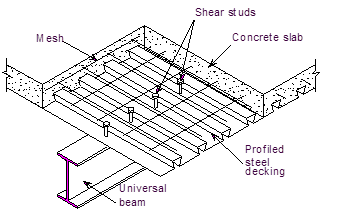

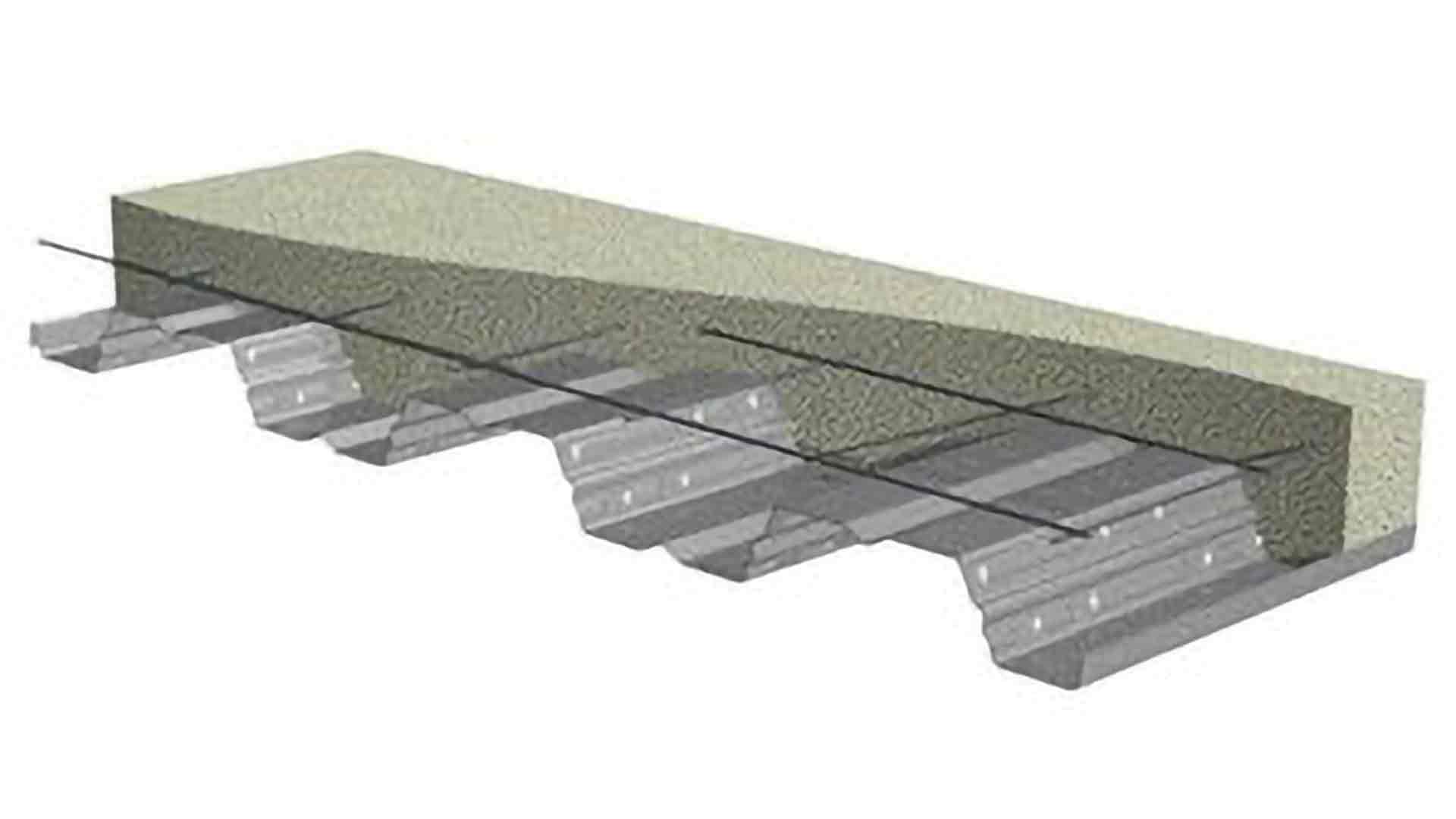

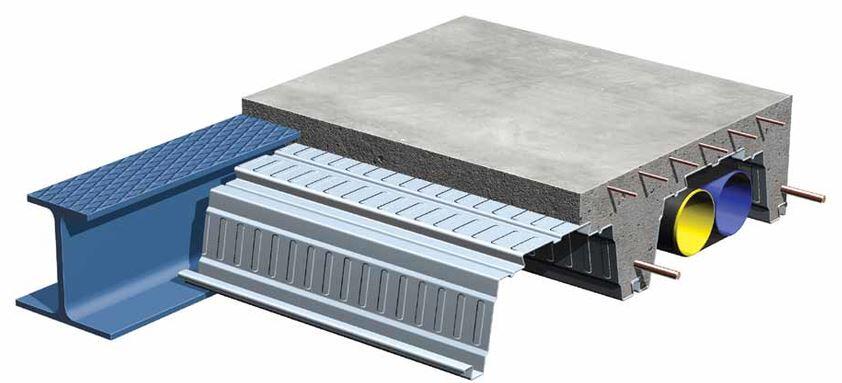

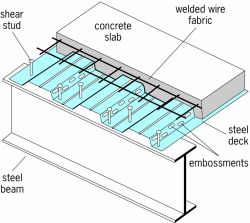

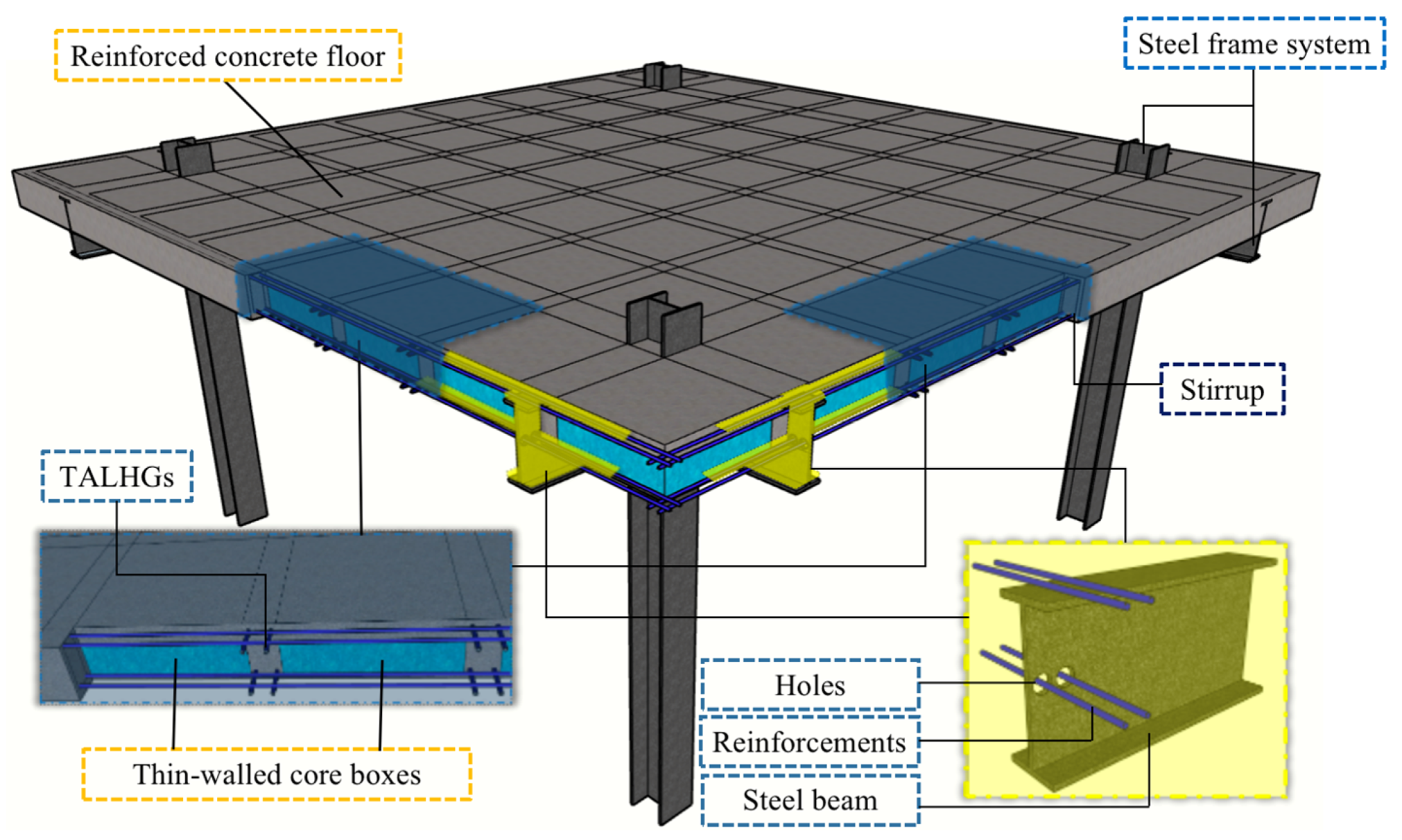

Composite steel and concrete floor construction is a type of building system that combines steel beams and columns with a concrete slab in order to create a strong and stable structure. This type of construction is common in high-rises, warehouses, and other large structures. The advantages of this system include increased structural integrity, cost savings, and reduced construction time. In addition, the composite floor construction system also provides additional support for heavy loads.

Advantages of Composite Steel and Concrete Floor Construction

Composite steel and concrete floor construction offers several advantages over traditional building systems. The main advantage is the increased strength of the structure due to the combination of steel and concrete. The steel beams provide a strong frame while the concrete slab provides added support for the weight of the structure. Additionally, this type of construction is typically less expensive than other types since it requires fewer materials and less labor. Furthermore, composite floor construction has been proven to reduce construction time when compared to non-composite systems.

Design Considerations for Composite Steel and Concrete Floor Construction

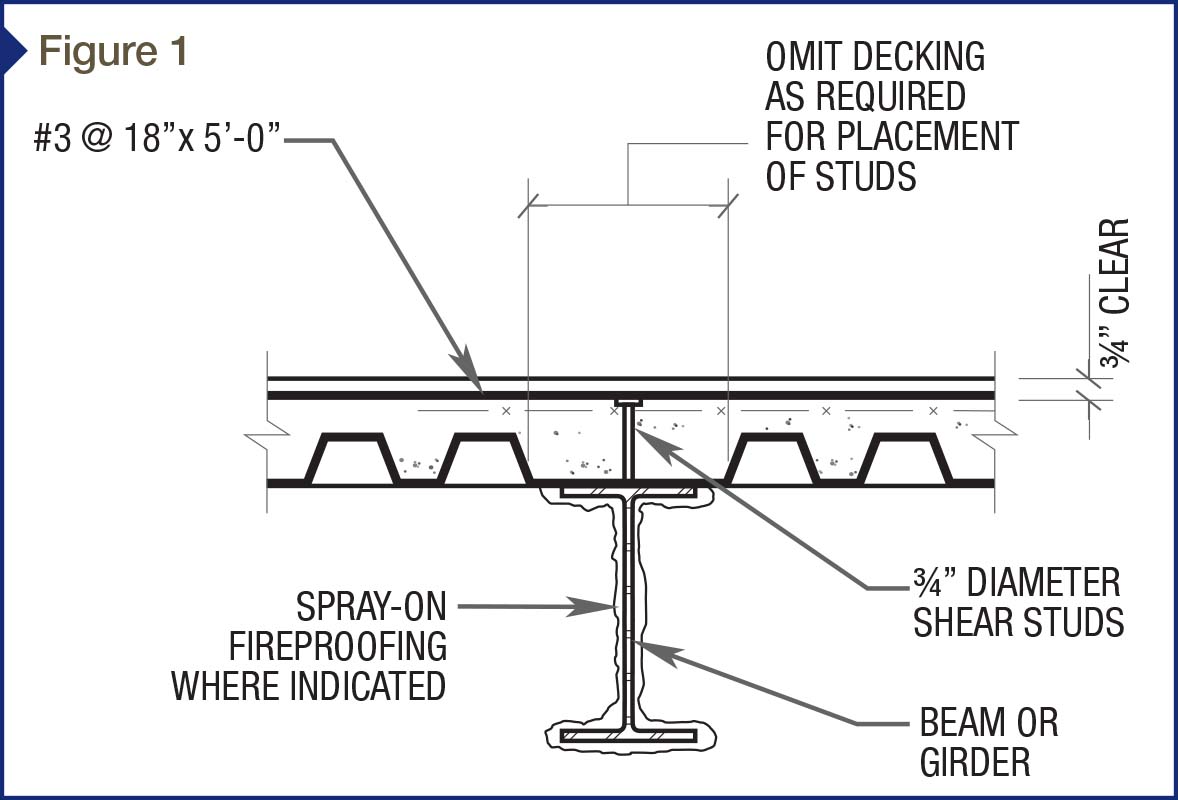

When designing a building with composite steel and concrete floor construction, there are several important considerations to keep in mind. It is important to ensure that the steel beams are properly connected to the concrete slab using appropriate fasteners. Additionally, it is essential to select appropriate steel components such as beams, columns, trusses, or girders that meet local building codes and standards. Furthermore, it is important to ensure that all components are properly designed so that they can accommodate the loads they will be subjected to during their lifetime. Finally, it is also important to consider how the structure will be insulated in order to maintain energy efficiency and comfort levels within the building.

Installation Process for Composite Steel and Concrete Floor Construction

The installation process for composite steel and concrete floor construction involves several steps. First, the foundation must be prepared by leveling it off before any components can be installed. Next, the steel components must be installed according to local building codes and standards using appropriate fasteners such as bolts or welding rods. After that, the concrete slab must be poured around the steel frame in order to create a strong bond between them. Finally, any insulation or waterproofing materials should be applied as necessary in order to maintain energy efficiency within the building.

FAQs Related To Composite Steel And Concrete Floor Construction

Q1: What are the advantages of composite steel and concrete floor construction?

A1: The main advantages of this type of floor construction are increased strength of the structure due to the combination of steel and concrete; cost savings due to fewer materials being used; reduced overall construction time; additional support for heavy loads; improved energy efficiency due to insulation; and improved comfort levels within buildings due to insulation as well.

Q2: What design considerations should be taken into account when designing a building with composite steel and concrete floor construction?

A2: When designing a building with composite steel and concrete floor construction, important considerations include ensuring that all components are properly connected using appropriate fasteners; selecting appropriate steel components such as beams, columns, trusses or girders that meet local building codes; ensuring that all components are properly designed so they can accommodate loads; considering how insulation will be applied In order to maintain energy efficiency and comfort levels within the building.

What are the advantages and disadvantages of composite steel and concrete floor construction?

Advantages:1. Increased strength and rigidity – A composite floor system combines the high strength of steel with the superior fire, acoustic and thermal insulation qualities of concrete, creating a structural system that is exceptionally strong.

2. Reduced weight – The use of composite steel and concrete construction has the potential to reduce overall building weight by up to 40%. This reduces the size of foundations required as well as reducing material costs.

3. Improved acoustic performance – Composite floors are often used in buildings where sound performance is a critical factor, such as music and performance venues, as they can provide superior acoustic insulation with minimal thickness compared to other traditional floor systems.

4. Reduced installation time – Composite steel and concrete floors can be quickly installed due to their pre-fabricated nature. This leads to reduced construction time as well as lower labour costs, making them ideal for fast-track projects.

Disadvantages:

1. High initial cost – Due to the large amount of materials required and labour involved in installing a composite floor system, they tend to be more expensive than other traditional floor systems such as timber or masonry construction.

2. Complexity of design – As composite floor systems involve multiple materials, they can be more difficult to design than other traditional floor systems due to their complex nature.

3. Limited fire resistance – While composite floors offer superior fire resistance compared to timber or masonry construction, they are still limited in this regard compared to other more specialized floor systems such as those utilising intumescent coatings or fire-rated boards.