The spectacular rise in each science as well as systems have more array of flooring choices for the builders as well as homeowners, and appears that concrete polish flooring is one of the hottest and latest options among others. Concrete flooring nowadays has developed into the latest flooring choice for homeowners as well as designers around the globe.

Images about Concrete Floor Control Joints

Staining is actually probably the most common method applied to concrete floors, acid stains are exclusively put on to the floor to create deep rich colours. Polished concrete flooring offers a slew of amazing benefits to home builders and renovators. You can make many geometric shapes as well as styles to create pretty much any sort of patent that you would like. The natural color proficiency of concrete will enhance some color scheme.

Joints In Polished Concrete Floors u2014 Dancer Concrete

The mantra is to cover the current concrete floor with a slim cement based overlay to create a fresh brand new picture to concentrate on. Once they've cured, new concrete installations are inexpensively and easily brought to a shine. When installing polished concrete flooring surfaces, the concrete is actually sanded with a diamond surfaced polishing machine.

Joints in Concrete Slabs JLC Online

Where To Locate Control Joints in Concrete – Construction Math

Epoxy Floor Coatings: What about the Cracks? What if I have a

flooring – Do I need to “fill in” concrete control joints before

Fill Concrete Joints with Joint Filler u0026 Sealant Premier Veneers

Concrete: Control Joints and Expansion Joints – Schedule Fred

Control Joints, Expansion Joints and Cold Joints in Concrete

Preparing for Concrete Cracks with Control Joints – Concrete Decor

How Often Do You Need Expansion Joints in Concrete? Kaloutas

CE Center – Building Movement Joints and BIM

What is a Concrete Expansion Joint? Total Concrete

Expansion Joint in Concrete u2013 Types and Characteristics – The

Related Posts:

- Concrete Floor Faux Finish

- Concrete Floor Anchor Kit

- Painted Concrete Floors In A Home

- Cleaning Adhesive Off Concrete Floor

- Outdoor Concrete Floor Paint Ideas

- Insulated Concrete Floor Slab Detail

- How To Insulate An Existing Concrete Floor

- Non Slip Concrete Floor Coatings

- How To Build A Shed With Concrete Floor

- Concrete Floor Polishing Equipment

Introduction to Concrete Floor Control Joints

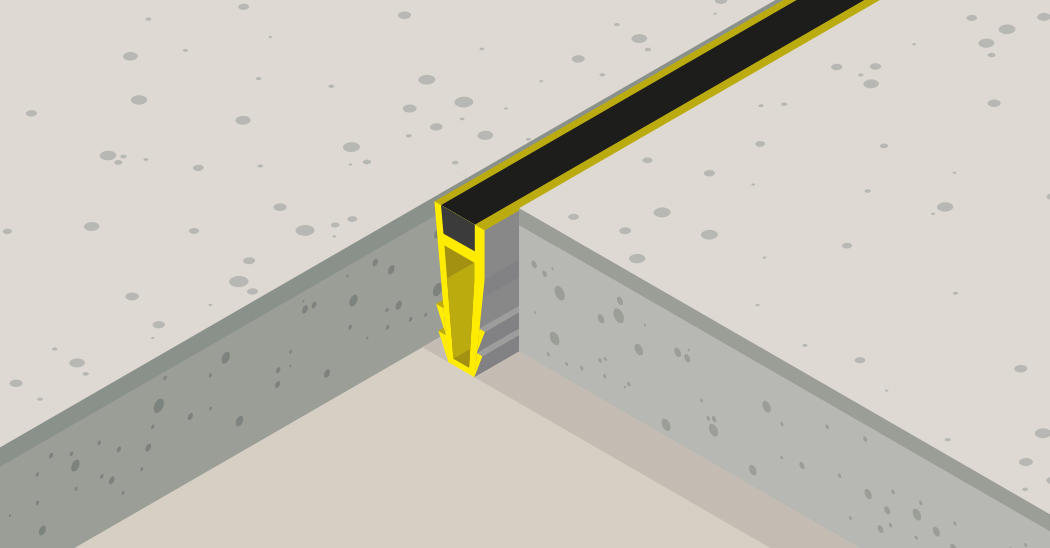

Concrete floor control joints are an important part of any concrete project. They are designed to help prevent cracking in the concrete, as well as provide a better appearance. Control joints allow contraction and expansion of the concrete slab by creating a weakened plane that permits movement and relieves stress. Without them, large cracks can form in the concrete, leading to costly repairs and maintenance. Understanding how and when to use control joints is essential for any successful concrete project.

What Are Concrete Floor Control Joints?

Concrete floor control joints are grooves or lines cut into the concrete slab that allows the slab to move without cracking or breaking. They are placed at regular intervals throughout the slab, usually between 10-15 feet apart. The grooves are typically cut with a saw and filled with flexible sealant or filler materials such as elastomeric joint sealants, polyurethane caulking or plastic backer rods. Control joints should be placed on all sides of structural elements, such as columns and walls, as well as along long runs of pavement, driveways and sidewalks.

How Do Control Joints Work?

Concrete is a strong material but it can be susceptible to shrinkage due to changes in temperature or moisture levels. This shrinkage can cause cracks to form in the concrete surface. By providing weakened planes that allow for movement, control joints help reduce cracking by allowing for expansion and contraction without buckling or breaking. In addition, they provide a better appearance than random cracks would produce.

When Should Control Joints Be Used?

Control joints should always be used when pouring new concrete slabs as they will help prevent cracking over time. It is best to start planning for control joints when designing the slab layout, as this will give you time to properly space them out according to their recommended intervals. For existing slabs that are already showing signs of cracking, it may be necessary to install additional control joints to help reduce further damage from occurring.

What Materials Should Be Used for Control Joints?

The type of material used for control joints should depend on the application and conditions of the area where they will be installed. Elastomeric joint sealants are usually best for interior applications where movement isn’t expected to be excessive. Polyurethane caulking is a good choice for exterior applications since it is more resistant to weathering than elastomeric sealants. Plastic backer rods should also be used in combination with sealants to help fill larger gaps and create an airtight seal. No matter what material is used, it should be flexible enough to accommodate movement yet still remain durable over time.

FAQs About Concrete Floor Control Joints

Q: What Is The Purpose Of A Control Joint?

A: The purpose of a control joint is to create a weakened plane that allows contraction and expansion of the concrete slab without cracking or buckling. This helps protect against potential damage caused by changes in temperature or moisture levels over time.

Q: How Far Apart Should Control Joints Be Placed?

A: Control joints should typically be placed between 10-15 feet apart but this can vary depending on the size of the slab and other factors such as climate conditions and amount of traffic expected . It is important to consult with an experienced concrete contractor to ensure the correct spacing is used for your particular application.

What is the purpose of a control joint in concrete?

Control joints are used to create weakened planes in concrete, allowing it to crack in a more uniform pattern when it is under stress. This helps to prevent large, random cracks from forming. Control joints also help reduce the amount of cracking due to shrinkage and temperature fluctuations.What are the benefits of using a control joint in concrete?

1. Control joints help reduce random cracking by providing a weakened plane in the concrete that can be easily identified, thus allowing for controlled cracking.2. Control joints also allow for thermal and shrinkage stresses to be relieved, which can help prevent excessive cracking.

3. They aid in the curing process by permitting a more uniform rate of drying and cooling, thus reducing curling and warping.

4. Control joints can reduce the stress concentration around corners and edges of concrete slabs, thus helping to prevent cracks from propagating along these points.

5. Lastly, control joints help improve the appearance of concrete by allowing for a neat, straight line instead of a jagged crack pattern.