Nonetheless, it's crucial for every home owner who's using the polished concrete floors to find out the way the polished floor is actually achieved when everything is said as well as done. Acid Stain concrete floorings have a bit of time and again proven their reliability when it comes to cost the, durability, and efficiency strength of the flooring.

Images about Concrete Floor Expansion Joint Covers

Places that have concrete polishing usually entice a great deal more people than those that do not have this concrete polishing on the floors. Depending on the color as well as the applications used doing staining concrete floor surfaces, the outcomes are able to emulate everything from lustrous marble improving to tanned lather to all natural stone.

Expansion Joint Cover Plates Construction Specialties

Polished concrete flooring can be the initial step on to creating an allergy free setting. Polished concrete is becoming a favorite office floor choice due to its longevity, easy maintenance, and great choice of styles and decorative choices. You can further mop it using hot, soapy drinking water, but only utilizing a mild detergent.

Floor Expansion Joint Covers – Thermal u0026 Seismic Joints Inpro

Restofit™ Floor Covers Construction Specialties

Expansion Joint Cover Plates Construction Specialties

Floor Expansion Joint Covers – Thermal u0026 Seismic Joints Inpro

Floor Expansion Joint Cover · QuickCover · Sika Emseal

Floor Expansion Joint Covers – Thermal u0026 Seismic Joints Inpro

Expansion Joint Cover Plates Construction Specialties

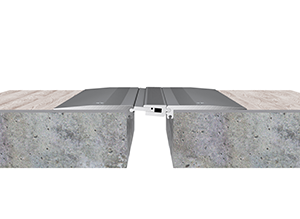

Flush ThinLine Single Seal Floor Expansion Joint 25MM 50MM

Aluminum Floor Expansion Joint Covers for Concrete – China

Serrated Stainless Steel Floor Expansion Joint Cover Plate FM

Floor Expansion Joint Covers – Thermal u0026 Seismic Joints Inpro

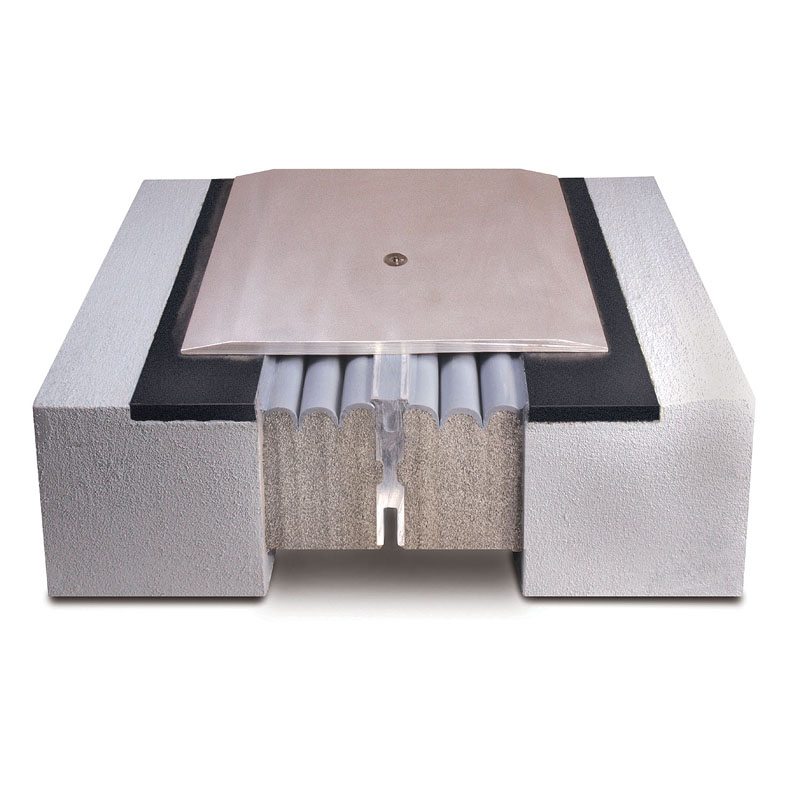

Seismic Expansion Joint · SJS System · Sika Emseal

Related Posts:

- How To Put A Concrete Floor Down

- Urban Concrete Floor Tiles

- Removing Cat Urine From Concrete Floor

- Air Bricks Concrete Floor

- Buckeye Proclaim Concrete Floor Coating

- How To Marbleize Concrete Floors

- How To Warm Up A Concrete Floor

- DIY Concrete Floors That Look Like Wood

- Concrete Floor Epoxy Finish

- Concrete Floor Electrical Box

Concrete Floor Expansion Joint Covers: Protecting and Enhancing Your Flooring Investment

Introduction:

Concrete floors are a popular choice for both residential and commercial spaces due to their durability, versatility, and aesthetic appeal. However, one important consideration when installing concrete flooring is the need for expansion joints. These joints allow the concrete to expand and contract with temperature changes, preventing cracks and other damage. To ensure the longevity and functionality of your concrete floors, it is crucial to invest in high-quality expansion joint covers. In this article, we will explore the importance of concrete floor expansion joint covers, their various types, installation methods, and frequently asked questions related to their usage.

I. The Importance of Concrete Floor Expansion Joint Covers:

a) Preventing Joint Damage:

Expansion joints are necessary in concrete floors to accommodate thermal expansion and contraction. Without proper protection, these joints can become vulnerable to damage from heavy traffic, moisture, chemicals, and debris. Concrete floor expansion joint covers serve as a protective barrier that prevents these elements from infiltrating the joints and causing deterioration.

FAQ: Why is it essential to protect expansion joints in concrete floors?

Answer: Concrete expands and contracts with temperature changes, which can lead to cracks if not properly managed. Expansion joint covers act as a safeguard against damage caused by external factors like traffic or moisture infiltration.

b) Enhancing Aesthetics:

Apart from their functional benefits, expansion joint covers also contribute to the overall aesthetics of your space. With a wide range of designs, colors, and finishes available on the market today, you can choose covers that seamlessly blend with your flooring or create a striking contrast for visual appeal.

FAQ: Can expansion joint covers be customized to match my flooring design?

Answer: Yes! Many manufacturers offer customization options for expansion joint covers. You can select from various colors, textures, patterns, or even incorporate branding elements into the design.

c) Ensuring Safety:

Concrete floor expansion joint covers play a vital role in maintaining a safe environment. By reducing the risk of tripping hazards and providing a smooth transition between different floor areas, these covers help prevent accidents and injuries.

FAQ: Are there specific regulations or standards regarding the use of expansion joint covers?

Answer: Yes, there are various regulations and standards, such as the Americans with Disabilities Act (ADA) guidelines, which address safety requirements for flooring transitions and tripping hazards. It is crucial to consult these standards when choosing and installing expansion joint covers.

II. Types of Concrete Floor Expansion Joint Covers:

a) Metal Covers:

Metal expansion joint covers are a popular choice due to their durability and strength. Made from materials such as aluminum, stainless steel, or brass, these covers offer excellent resistance against heavy loads, abrasion, and impact. They are suitable for both indoor and outdoor applications and are often used in high-traffic areas like airports, malls, or industrial facilities.

FAQ: What are the advantages of metal expansion joint covers?

Answer: Metal covers provide superior strength and durability compared to other materials. They can withstand heavy loads and offer excellent resistance against impact or abrasion. They are also fire-resistant and can be customized with various finishes to match your aesthetic preferences.

b) Rubber Covers:

Rubber expansion joint covers are known for their flexibility, allowing them to accommodate movement while maintaining a watertight seal. These covers are primarily used in areas where noise reduction is required, such as hospitals, schools, or residential buildings. Rubber covers also provide a cushioning effect that reduces the stress on joints caused by heavy Foot traffic or vehicular loads.

FAQ: Are rubber expansion joint covers suitable for outdoor applications?

Answer: Rubber covers can be used for both indoor and outdoor applications. However, they may require additional protection or maintenance in outdoor environments to withstand exposure to UV rays, extreme temperatures, and other weather conditions.

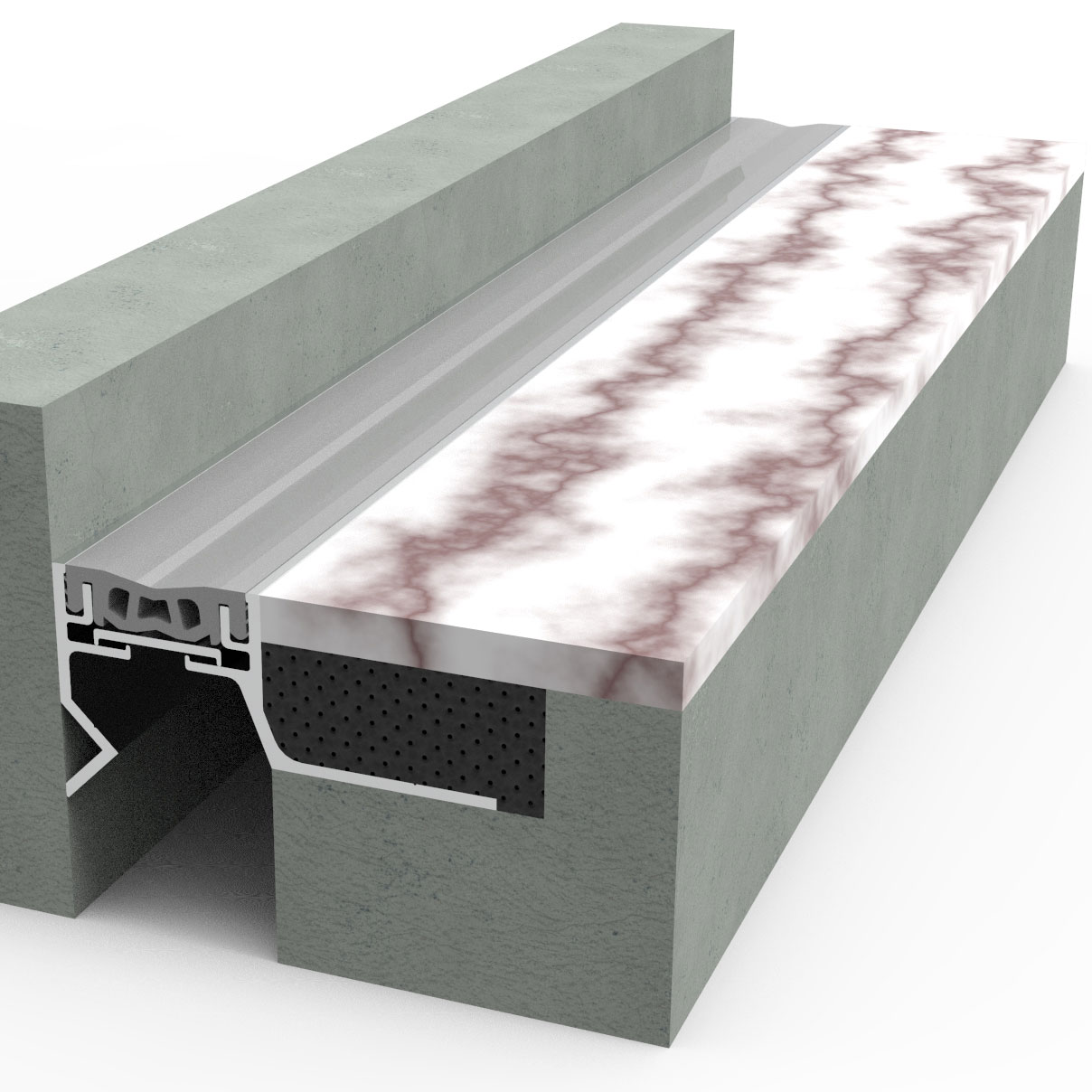

c) Hybrid Covers:

Hybrid expansion joint covers combine the benefits of both metal and rubber materials. These covers typically have a metal base for strength and durability, with a rubber insert to provide flexibility and accommodate movement. Hybrid covers are often used in areas with high foot traffic and heavy loads, such as shopping centers, sports stadiums, or transportation hubs.

FAQ: What are the advantages of hybrid expansion joint covers?

Answer: Hybrid covers offer the best of both worlds by combining the strength and durability of metal with the flexibility of rubber. They provide excellent resistance against heavy loads, impact, and abrasion while accommodating movement and maintaining a watertight seal.

In conclusion, concrete floor expansion joint covers offer several benefits including moisture infiltration prevention, enhanced aesthetics, and improved safety. There are different types of covers available, including metal, rubber, and hybrid options, each with their own advantages depending on the specific application requirements.