Staining concrete flooring is something that you can conveniently do yourself or even pay an expert to do if you want a far more complex decorative concrete plan. The advantages of polished concrete floors are extremely numerous and for anybody aiming to have great flooring, it is wise not to appear any more than the polished flooring surfaces.

Images about Concrete Floor Joint Filler

Staining is probably the most common technique applied to concrete flooring, acid stains are directly put on to the floor to create strong wealthy colours. Polished concrete flooring has a slew of advantages to home builders as well as renovators. You can make several geometric shapes as well as designs to form pretty much a patent that you would like. The natural color capabilities of concrete will accentuate some color scheme.

Epoxy vs. Polyurea Joint Fillers: Which is best? – Concrete Decor

You'll have a convenient subfloor for epoxy, tile, carpeting, or maybe whatever area you desire if you ever before get tired of the bare concrete flooring appear. This undoubtedly becomes the reason why the demand for polished concrete floors now has skyrocketed, as well as individuals are opting for this as an economical and innovative option outdoor & indoor.

Akonaflex™ Pro Self-Leveling Expansion Joint Filler – 10 fl. oz

Polyurea Joint Filler/sealer

3003 Polyurea Joint Filler for Interior Concrete Control Joints

VersaFlex Filling the Need for Fast Turn Around, Durable

Industrial concrete joint filler Dynaflex JF-85 is fast-setting

How to Repair Concrete Expansion Joints – Pro Tool Reviews

ElastiPoxy Concrete Joint u0026 Crack Filler Kit (2-qts.) – Flexible Epoxy Joint Sealant for Floor-to-Wall Joints, Contraction Joints, Cracks in Concrete

3246 Polyurea Flexible Expansion Joint Filler Exterior Interior Low Temp -20°F

Concrete Expansion Joints at Lowes.com

VersaFlex Filling Control Joints – VersaFlex

Concrete Joint Filler for Control and Expansion Joints

Concrete Expansion Joints (Filler Material) – Easy To Handle And

Related Posts:

- Pouring A Concrete Floor In A Garage

- Industrial Strength Concrete Floor Cleaner

- Concrete Floor Sealant Recommendation Needed

- Preparing Concrete Floor For Acid Stain

- Dan Lynch Concrete Floors

- Concrete Floor Clear Coat

- Concrete Floor Cleaning Tips

- Level Concrete Floor Before Laminate

- Acid Stain Concrete Floors Yourself

- Concrete Floor Drain Installation

Introduction

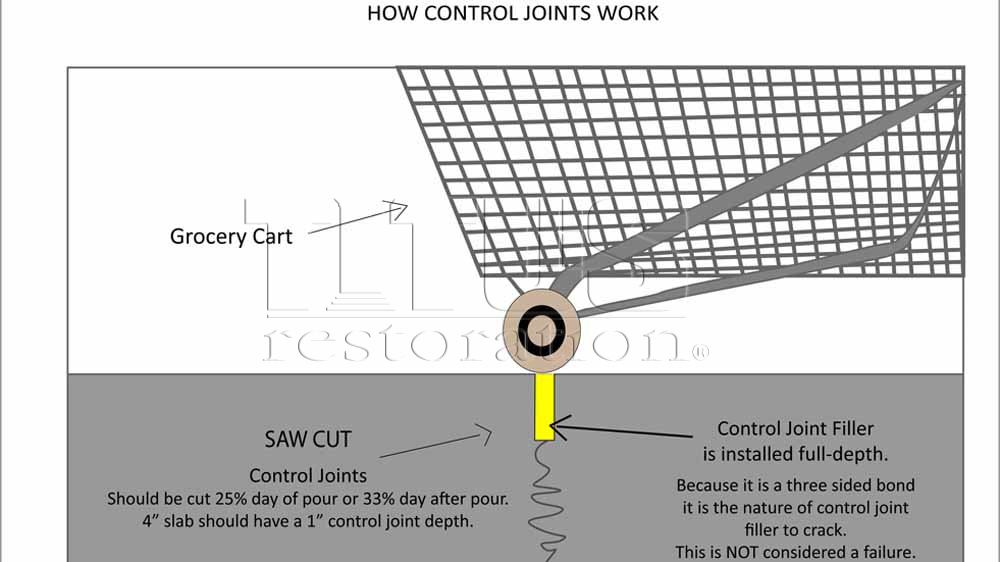

Concrete floor joint filler is an important component of any concrete flooring project. It not only helps protect the integrity of the floor, but also enhances its aesthetic appeal. It is a special material that is designed to fill in the spaces between two pieces of concrete, creating a seamless connection and preventing water or other liquids from seeping into the joints. In this article, we will discuss the different types of joint fillers available, their benefits, and tips for selecting the right product for your project.

Types of Concrete Floor Joint Filler

There are a variety of concrete floor joint fillers on the market today. Each type has its own unique properties that make it suitable for certain applications.

Epoxy-Based Joint Fillers

Epoxy-based joint fillers are one of the most popular options for filling in joints between concrete surfaces. This type of joint filler is made from a blend of polymer resins and hardeners that form an extremely strong bond when cured. It is highly resistant to water and other liquids, making it an ideal choice for wet areas such as showers or pools. Additionally, epoxy-based fillers can be tinted to match the surrounding concrete for a more seamless appearance.

Silicone-Based Joint Fillers

Silicone-based joint fillers are another popular option for concrete floors. Unlike epoxy-based products, silicones are not as rigid and provide more flexibility when applied to joints. This makes them ideal for use in high traffic areas where movement is likely to occur over time. Additionally, silicone-based products often come in clear or translucent colors so they won’t distract from the natural look of your concrete surface.

Urethane-Based Joint Fillers

Urethane-based joint fillers are a great option if you’re looking for a durable solution that will last for many years without needing to be replaced. Like silicones, urethanes provide more flexibility than epoxies and can withstand movement over time without cracking or breaking down. Urethanes also offer excellent adhesion to both concrete surfaces and other materials such as tile or grout.

Benefits of Concrete Floor Joint Filler

Using a joint filler on your concrete floor has several distinct advantages:

Durability: Joint fillers are designed to last for many years without needing to be replaced or repaired. This means that once it’s applied, you won’t have to worry about continuous maintenance or repair costs down the line.

Water Resistance: Most joint fillers are designed to be highly water resistant, meaning that any liquid spilled on them will not seep into the joints and cause damage over time. This makes them perfect for use in wet areas such as bathrooms or kitchens where spills are likely to occur frequently.

Aesthetic Appeal: Joint fillers can be tinted to match the surrounding concrete surface so they won’t distract from its natural beauty. Furthermore, they create a seamless connection between two pieces of concrete which can give your floor a more polished and professional look.

FAQs about Concrete Floor Joint Filler

Q: What is the best type of joint filler for my project?

A: The best type of joint Filler for your project will depend on the specific application and the type of concrete surface you are filling. Epoxy and urethane-based products are typically the most durable, while silicone-based products offer more flexibility.

Q: How long does it take to install joint filler?

A: The installation time will vary depending on the size of the joint and the type of product being used. Generally speaking, most joint fillers can be installed in a few hours or less.

Q: How can I ensure the best results when filling concrete joints?

A: To ensure the best results, it is important to properly clean and prepare the surface before applying the joint filler. Additionally, make sure to follow all of the manufacturer’s instructions for application and curing times.