The color of the tile may be used as the same color to spot the concrete floor. Concrete floors are durable and hard. The concrete floors is there to remain and once you move on at a bit of stage, the new owners will have the ability to enjoy the benefits this sort of flooring provides. Most standard flooring have arduous cleaning demands.

Images about Concrete Floor Joint Repair

On top of a mirror-like gloss, concrete flooring could be spruced up with embedded patterns, lines, images, grids and other designs. They impart a luxurious richness that can't be attained by any other flooring. With more properties being crafted in a modern style, concrete polishing floors is actually growing in bounds and leaps. Abrasive pads file down the top surface of the concrete.

Expansion Joint Repair (A Complete Guide)

The spectacular rise in both science as well as systems have more array of flooring alternatives for the builders along with homeowners, as well as seems that concrete polish flooring is among the hottest and latest options among others. Concrete flooring today has developed into a brand new flooring option for homeowners as well as designers around the world.

Concrete Floor Joint Repair Solutions – Tremco CPG APAC Blog

Control Joint Repair – Professional Warehouse Floor Repair Contractors

Repairing Joints In Concrete Slabs Concrete Construction Magazine

Blog

Floor Joint Reseal Repair – CoGri USA INC

Concrete Floor Crack Repair – CG Flooring Systems

How to Repair Concrete Expansion Joints – Pro Tool Reviews

Repair joints concrete floor

Floor Joint Repairs Industrial Floor Joint Repairs

Floor Joint Repairs Industrial Floor Joint Repairs

Repair joints concrete floor

Concrete Joint Filling and Repair – Glossy Floors

Related Posts:

- Concrete Floor Heating And Cooling

- Stained Concrete Floor Tiles

- Outdoor Concrete Floor Coverings

- Stained Concrete Floors Cleaning

- Concrete Floor Garage Paint

- Grinding Down High Spots Concrete Floor

- Fixing Sole Plate To Concrete Floor

- Cheapest Floor Covering For Concrete Floor

- How To Stain And Polish Concrete Floors

- Concrete Floor Paint Interior

Concrete Floor Joint Repair: A Comprehensive Guide

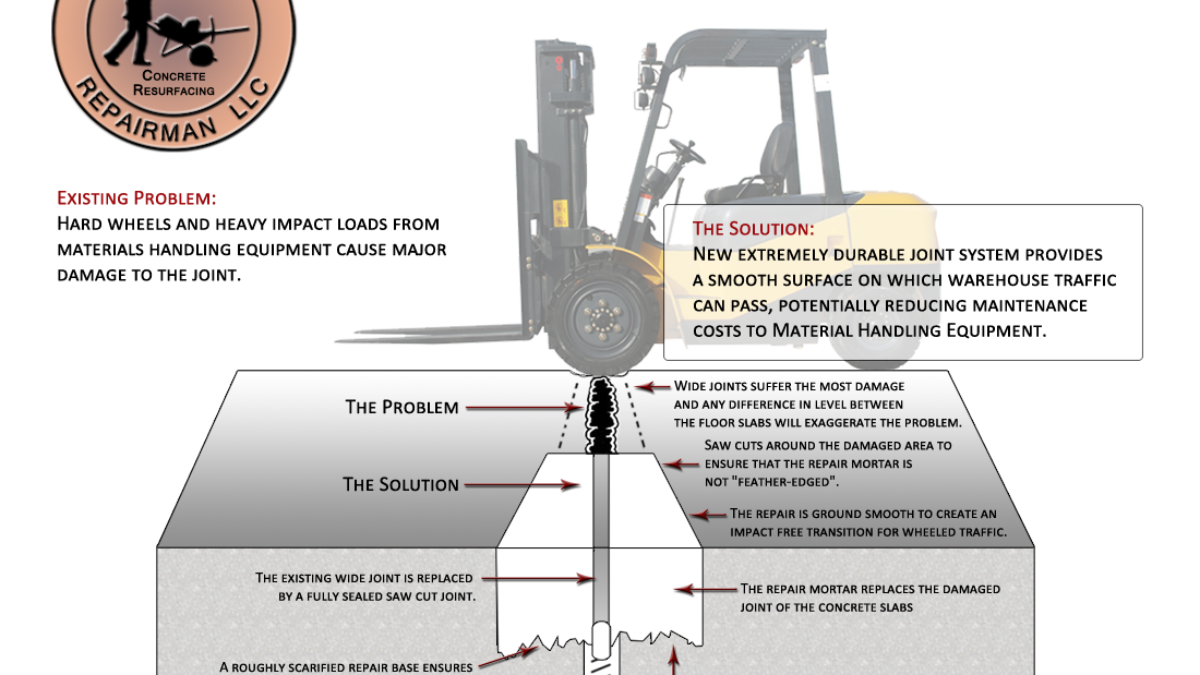

Concrete floors are a popular choice for both residential and commercial applications, as they are durable, low maintenance, and aesthetically pleasing. However, with age and wear and tear, concrete floors can start to develop cracks and joints. If not properly repaired, these joints can cause further damage to the flooring. Here’s a comprehensive guide on how to repair your concrete floor joints.

What are Floor Joints?

Floor joints, also known as control joints or expansion joints, are intentional spaces between sections of concrete designed to absorb any movement caused by temperature changes and other factors. They ensure that the concrete does not crack due to thermal expansion and contraction. These joints can be found in many areas of buildings such as warehouses, garages, and basements.

Why are Floor Joints Important?

Floor joints play an important role in ensuring that your concrete floor remains in good condition for years to come. Without them, the concrete would be more prone to cracking due to thermal expansion and contraction. Additionally, floor joints help reduce the risk of water infiltration into the concrete slab which can cause mold growth and other problems. Finally, floor joints help reduce stress on the concrete slab which can lead to premature cracking and deterioration.

How Do You Repair Floor Joints?

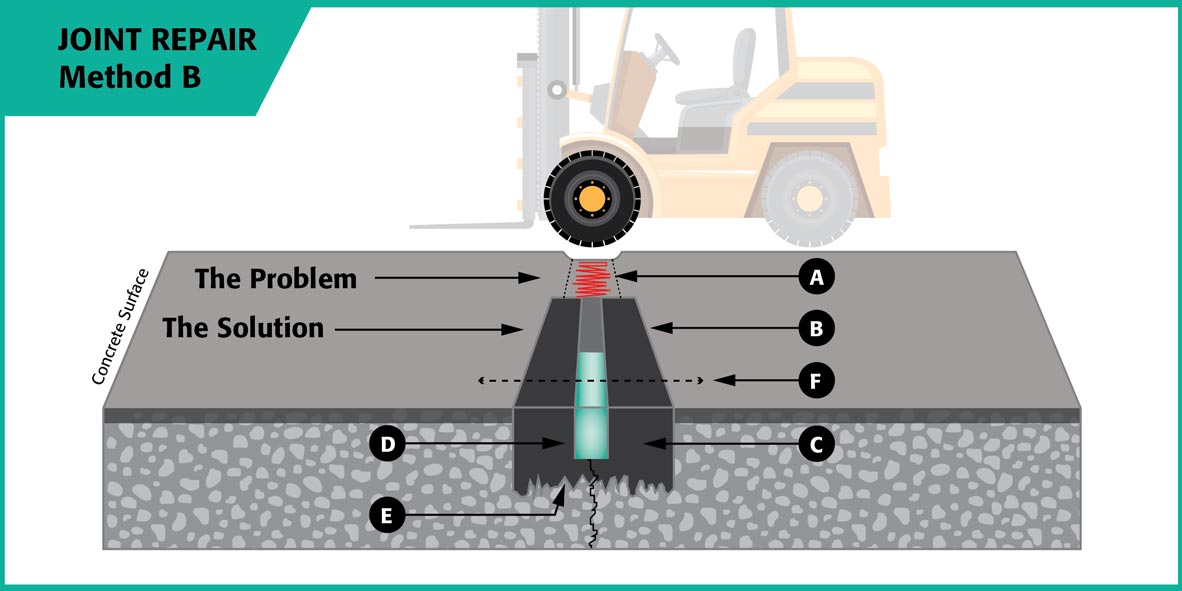

Repairing floor joints is relatively simple if done correctly. The first step is to clean out the joint using a wire brush or other suitable tool. This will remove any dirt or debris that may be obstructing proper repair work. Once cleaned out, you should inspect the joint for any signs of damage or other issues such as spalling or crumbling concrete. If present, these should be repaired prior to patching the joint.

Next, you’ll want to fill the joint with a suitable material such as epoxy or polyurethane caulk. This material should be applied evenly along the length of the joint making sure it fully fills all gaps and crevices. Once applied, allow it to set according to manufacturer instructions before smoothing over with a trowel or other suitable tool such as a putty knife.

Finally, it’s important to seal over the repaired joint with an appropriate sealant such as acrylic sealer or polyurethane sealer in order to protect it from water infiltration and other environmental elements that could cause damage over time. Sealant should be applied in two coats allowing each coat sufficient time to dry before applying the next one. Once complete, your repaired joint should be protected for years ahead!

FAQs About Concrete Floor Joint Repair

Q: How do I know if my floor joint needs repairing?

A: The best way to tell if your floor joint needs repairing is by inspecting it for signs of damage such as cracks or crumbling concrete. If present then repairs should be undertaken as soon as possible in order to prevent further damage occurring in future.

Q: What materials should I use for repairing floor joints?

A: The best materials for repairing floor joints are epoxy or polyurethane caulk as they provide excellent adhesion properties and resistance against water infiltration and other environmental elements that could cause damage over time.

How much does it cost to repair a concrete floor joint?

The cost of repairing a concrete floor joint will depend on the size and complexity of the repair, as well as the type of materials used. On average, repairs typically range from $50-$150 per linear foot.What materials are needed to repair a concrete floor joint?

1. Angle grinder2. Concrete sealant

3. Caulking gun

4. Chisel or hammer

5. Vacuum cleaner

6. Joint filler (polyurethane, epoxy, etc.)

7. Patching compound

8. Trowel

9. Paintbrush

10. Paint (if desired)

What tools are needed to repair a concrete floor joint?

1. Hammer and chisel2. Caulking gun

3. Concrete grinder

4. Joint sealant

5. Concrete saw

6. Trowel

7. Putty knife

8. Vacuum cleaner

9. Paintbrush (if desired)

10. Paint (if desired)