Concrete floors could be scored to produce a pattern by opting for shallow cuts having a circular saw. With all this features concrete floorings are starting to be quite popular day by majority of individuals and day are actually opting for the same.

Images about Concrete Floor Preparation For Wood Flooring

The tips of painting both polished concrete as well as terrazzo floors include the most vital task of all, finding the best sort of paint for the job. They are the best uses for polished concrete floor surfaces as public authorities estimate the long-term cost benefits of various other floorings. Apart from that, the concrete floors improving offers a feeling of protection to home owners.

Concrete Subfloor Preparation Leveling for Laminate Hardwood Floor Installation MrYoucandoityouself

Polished concrete flooring is an excellent strategy to save resources. Concrete flooring takes a little while to warm up, but is incredibly effective from having that heat in, meaning your house will stay hot on winter nights. Maintaining your concrete floor coating is very simple. Polished concrete floors can be really simple to maintain and manage.

Prepping Concrete Slabs for Hardwood Floor Installation City

Wood Floors on a Concrete Slab, Ep. 2: Preparation – Fine Homebuilding

How to Prep Concrete for a Wide Plank Hardwood Flooring

Installation of Wooden Flooring over Concrete Slab – The Constructor

Installing a Hardwood Floor Over a Concrete Slab – American

Hardwood floor preparation : Gandswoodfloors

How to Prepare a Wood Sub-Floor BuildDirect® Learning

How To Level Concrete Subfloor: Preparation for Laminate or Hardwood floor Mryoucandoityourself

Installing Engineered Hardwood on Concrete – Twenty u0026 Oak

Installing Laminate Flooring Over Concrete – The Ultimate Guide

Glue Wood Flooring to a Concrete Slab – Fine Homebuilding

How to Avoid Unnecessary Hardwood Flooring Failures 2019-12-10

Related Posts:

- Concrete Floor Adhesive Remover

- Leveling A Concrete Floor For Laminate

- Painting Concrete Floors In Garage

- Crack In Concrete Floor Slab

- Underfloor Heating Existing Concrete Floor

- ding Paint Off Concrete Floor

- Construction Of Concrete Floor

- Tremix Concrete Flooring Specifications

- Concrete Floor Joist System

- Concrete Floor Topping Mix Ratio

Concrete Floor Preparation For Wood Flooring

Introduction:

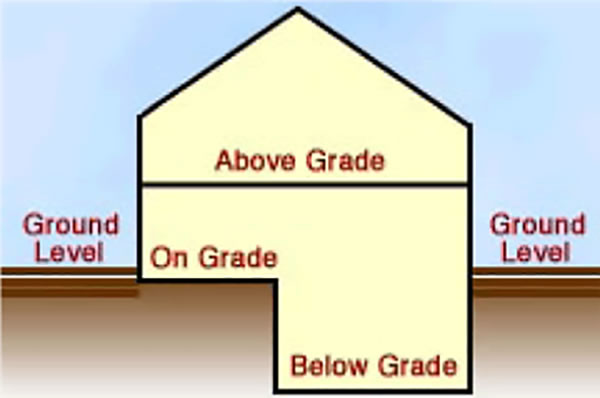

When it comes to installing wood flooring, proper concrete floor preparation is essential to ensure a long-lasting and visually appealing result. Preparing the concrete surface properly helps to create a smooth and level base for the wood flooring, preventing issues such as unevenness, squeaks, and premature wear. In this article, we will guide you through the step-by-step process of preparing your concrete floor for wood flooring installation.

1. Clearing the Area:

Before beginning the preparation process, it is crucial to clear the area of any furniture, debris, or existing flooring materials. Sweep or vacuum thoroughly to remove all dust and dirt from the surface. This will provide a clean canvas for the subsequent steps of preparation.

2. Moisture Testing:

One of the most critical aspects of concrete floor preparation is checking for moisture. Moisture can seep through the concrete slab and cause damage to wood flooring over time. To test for moisture, tape a plastic sheet securely to different areas of the concrete floor and leave it for 24 hours. If condensation or dark spots appear under the plastic, it indicates excessive moisture in the concrete and further steps need to be taken before proceeding with wood flooring installation.

FAQ: How do I address excessive moisture in my concrete floor?

Answer: If you find excessive moisture in your concrete floor, it is important to identify and rectify the source of moisture before proceeding. This may involve installing a vapor barrier or taking measures to improve drainage around your property. Consulting with a professional contractor or flooring specialist is recommended in such cases.

3. Repairing Cracks and Imperfections:

Next, carefully inspect the concrete surface for cracks, holes, or other imperfections that need repair. Small cracks can be filled with an appropriate concrete crack filler using a putty knife, while larger cracks may require more extensive repair work. It is crucial to ensure that the repaired areas are completely dry and cured before moving forward.

FAQ: Can I install wood flooring directly over minor cracks in the concrete?

Answer: While small, hairline cracks in the concrete may not pose a significant issue, it is still recommended to fill them to prevent any potential problems in the future. Filling cracks creates a smoother surface for the wood flooring installation and helps to maintain its structural integrity over time.

4. Grinding or Shot Blasting:

To create a level and smooth surface for wood flooring installation, it is often necessary to grind or shot blast the concrete floor. Grinding involves using a diamond grinder to remove any high spots or unevenness on the concrete surface, while shot blasting uses small steel pellets to blast away any imperfections. This step not only ensures a level base but also enhances the adhesion of the subsequent layers.

FAQ: Can I skip grinding or shot blasting if my concrete floor already appears level?

Answer: Even if your concrete floor appears level, grinding or shot blasting is still recommended. This process not only removes any imperfections but also roughens up the surface, allowing better adhesion between the concrete and subsequent layers such as adhesive or underlayment.

5. Applying Moisture Barrier:

To further protect the wood flooring from moisture damage, applying a moisture barrier is crucial. A moisture barrier helps to prevent moisture from seeping through the concrete slab and reaching the wood flooring above. There are different types of moisture barriers available, including liquid membranes, sheet membranes, and epoxy coatings.

FAQ: Do I need a moisture barrier if I have already addressed excessive moisture in my Concrete floor?

Answer: Yes, even if you have addressed excessive moisture in your concrete floor, it is still recommended to apply a moisture barrier. This additional layer of protection helps to ensure that any remaining moisture will not damage the wood flooring in the future. It is best to consult with a professional contractor or flooring specialist to determine the most suitable type of moisture barrier for your specific situation.

6. Installing Underlayment:

Before proceeding with wood flooring installation, it is important to install an underlayment. Underlayment acts as a cushioning layer between the concrete and the wood flooring, providing insulation and reducing noise transmission. There are various types of underlayment available, such as foam, cork, or rubber, and the choice depends on factors such as subfloor condition and desired level of sound insulation.

FAQ: Is underlayment necessary for wood flooring installation?

Answer: Yes, underlayment is necessary for wood flooring installation. It provides several benefits, including sound insulation, moisture protection, and added comfort underfoot. Additionally, underlayment can help to prolong the lifespan of the wood flooring by acting as a barrier against moisture from the concrete slab.

By following these steps and addressing any potential issues beforehand, you can ensure a successful and long-lasting wood flooring installation on your concrete floor. It is always advisable to consult with professionals or specialists in the field to ensure proper techniques and materials are used for your specific project.