The advantages that a single could get through the polished concrete floors are really numerous and some of them include the fact that the polished concrete floors provide a true low cost solution to the notion of floors as a well as providing a good choice in terms of environmentally friendly options.

Images about Concrete Floor Slab Construction Joints

You will be surprised to know the possibilities of floor are unlimited with polished concrete floors. Right now there are huge amounts of looks for the office floor that can be achieved with different polished concrete flooring. Concrete flooring polishing causes a planet of difference between the a floor and some other kind of floor.

Joints in Concrete Construction – Types and Location of Concrete

Today's concrete for floor surfaces comes in a wide range of colors that are different, and it's feasible to include in a number of other elements and different stone to produce a polished concrete floor a thing of beauty. Concrete flooring has appeal which is great for people keen on eco-friendly construction.

Control Joints in Concrete [a deep study] – Structural Guide

Types of Concrete Construction Joints Tips on Placing Joints in

Joints in Concrete Slabs on a Grade u2014 What, why, u0026 how? u2013 Nevada

Construction joints: Ideal Joint Classic, Performance and Dual

Joints in Concrete Slabs JLC Online

Construction Joint In Concrete Types Of Construction Joints

![]()

Placing Joints in Concrete Flatwork- Why, How, and When

5 Different Types Concrete Joints: How To Make u0026 Repair

Typical Concrete Slab Construction Joint (pdf)

Types of Concrete Construction Joints Tips on Placing Joints in

Construction Joints in Concrete Engineersdaily Free

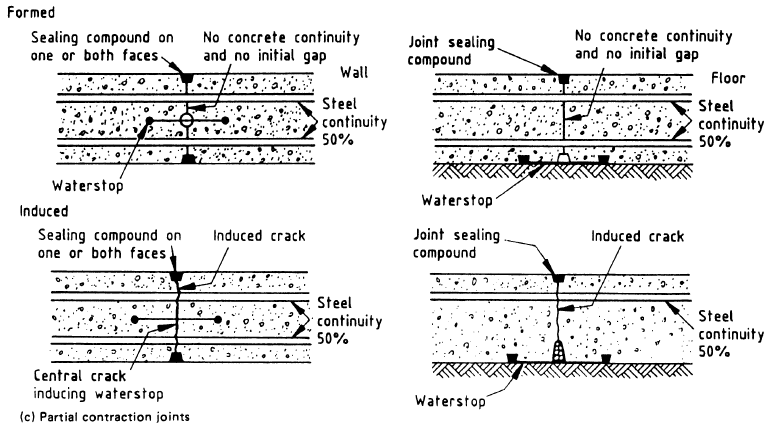

Concrete contraction joints are intended to create weakened planes

Related Posts:

- DIY Concrete Floor Tiles

- Painting Concrete Floors In Your House

- Staining Concrete Floors Yourself

- Pitted Concrete Floor

- Indoor Concrete Flooring Ideas

- Do It Yourself Interior Concrete Floors

- Resealing Concrete Floors

- Concrete Floor Rubber Coating

- White Concrete Floors Interior

- Decorative Concrete Floors DIY

Concrete Floor Slab Construction Joints: A Comprehensive Guide

Introduction:

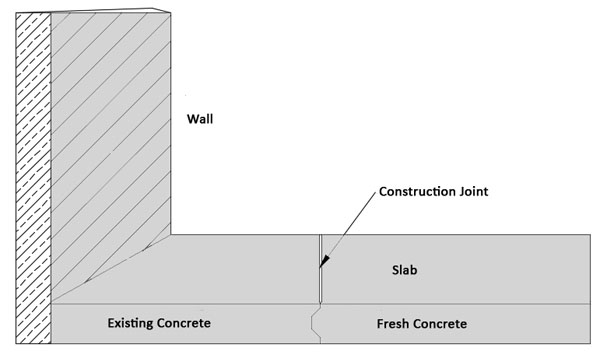

Concrete floor slabs are an essential component of many construction projects, providing a durable and long-lasting foundation for a variety of structures. However, to ensure the structural integrity of these slabs, proper attention must be given to the construction joints. In this article, we will delve into the intricacies of concrete floor slab construction joints, discussing their importance, types, installation methods, and common FAQs associated with them.

I. Importance of Concrete Floor Slab Construction Joints:

Construction joints play a crucial role in minimizing cracking and ensuring the overall stability of concrete floor slabs. They are designed to accommodate movement caused by thermal expansion, shrinkage, and settling, preventing unsightly cracks from forming and compromising the structural integrity of the slab.

FAQ 1: Why are construction joints necessary in concrete floor slabs?

Answer: Construction joints allow for controlled cracking at predetermined locations, relieving stress that would otherwise lead to random cracks throughout the slab. They also provide an opportunity to make adjustments or modifications during the construction process.

FAQ 2: What happens if construction joints are not properly installed?

Answer: Without proper construction joints, concrete floor slabs are more susceptible to uncontrolled cracking. These cracks can compromise the strength and durability of the slab, leading to costly repairs or even complete failure.

II. Types of Concrete Floor Slab Construction Joints:

There are several types of construction joints commonly used in concrete floor slabs. Each type serves a specific purpose and should be carefully selected based on project requirements.

1. Construction Joint with Keyway:

This type of joint includes a keyway, which is essentially a groove formed along the joint’s length. The keyway helps maintain alignment between adjacent sections of the slab while allowing limited movement.

FAQ 3: What is the purpose of a keyway in a construction joint?

Answer: The keyway facilitates load transfer between adjacent sections of the slab, preventing differential settlement and reducing the risk of cracks forming at the joint.

2. Construction Joint with Dowels:

In this type of joint, dowel bars are inserted into one side of the joint and extend into the adjacent section. Dowels ensure proper load transfer between sections, allowing for differential movement while maintaining structural continuity.

FAQ 4: Why are dowels used in construction joints?

Answer: Dowels provide load transfer across construction joints, enabling independent movement between sections while preventing vertical or horizontal displacement.

3. Construction Joint with Tie Bars:

Tie bars are steel reinforcement elements that span across the joint, securing adjacent sections of the slab together. They are commonly used in large-scale projects where high loads and significant movement are expected.

FAQ 5: How do tie bars differ from dowels in construction joints?

Answer: While both tie bars and dowels provide load transfer, tie bars offer greater resistance to shear forces, making them suitable for applications involving heavy loads or significant movement.

III. Installation Methods for Concrete Floor Slab Construction Joints:

Proper installation is crucial to ensure the effectiveness of construction joints in concrete floor slabs. Below, we discuss two common methods used during the installation process.

1. Formed Construction Joints:

Formed joints are created by placing temporary forms or bulkheads at predetermined locations before pouring each section of the slab. These forms prevent concrete from flowing into adjacent areas and create a straight edge for later joining.

FAQ 6: What materials can be used as forms for formed construction joints?

Answer : Common materials used as forms for formed construction joints include wood, metal, or plastic. These materials should be sturdy and able to withstand the pressure of the poured concrete. 2. Sawed Construction Joints:

Sawed joints are created by using a concrete saw to cut through the hardened concrete at a predetermined location. This method allows for controlled cracking and helps relieve stress on the slab, reducing the risk of random cracks forming.

FAQ 7: When should sawed construction joints be made?

Answer: Sawed construction joints should be made as soon as possible after the concrete has hardened enough to prevent excessive raveling or spalling during cutting. The timing will vary depending on factors such as temperature and mix design.

Overall, selecting the appropriate type of construction joint and following proper installation methods are essential for ensuring the durability and performance of concrete floor slabs. It is important to consult with professionals and consider project requirements when making these decisions.