The expression which pertains to a number of decorative concrete flooring options which typically end up leaving a concrete surface preferably exposed as the last final and final floor finishing. For a thorough cleaning, clean the floor with a concrete cleaner and then follow with a great rinsing. Little bumps & ridges are created on textured concrete floor surfaces for a better traction while walking.

Images about Concrete Floor Tolerances

You can find a few places that discover this type of polished concrete flooring quite helpful. The concrete floor even offers different degrees of absorbency together with the acid giving the floor a marble effect that can seem hitting. To polish the concrete floor brings out the beauty of the floor and leaves home owners with the very best building material.

Slab surface flatness vs slab surface finish u2013 SMD Structural

Even though you may be in a position to keep your floor war with radiant floor heating installed, if you don't have the choice and concrete flooring can be a little cool. Polished concrete floors, lengthy consigned to finished basements and industrial spaces, are actually producing well-deserved inroads into residential houses.

Floor Flatness Surveying and Testing – Face Consultants

CONSTRUCTION DEFECTS EXPERT post-tensioned concrete decks

ACI Tolerances for Concrete Construction Concrete Construction

A High Tolerance Concrete Flooring Collaboration – Face Consultants

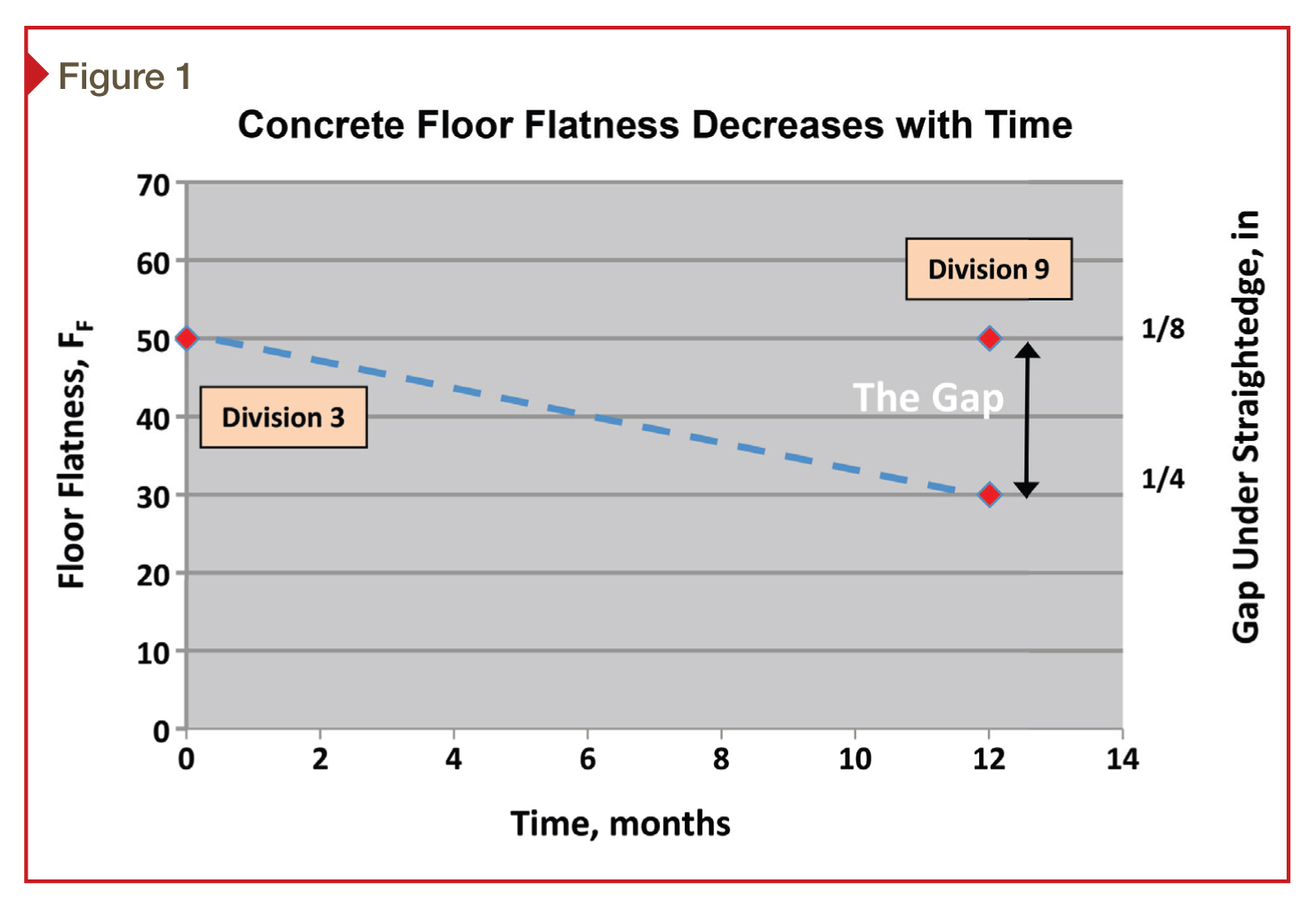

Bridging the Specification Gap between Divisions 03 and 09

A High Tolerance Concrete Flooring Collaboration – CoGri Group Ltd

What Are Superflat Floors? Superflat Floors

Floor Flatness and Levelness – FF u0026 FL Numbers – Concrete Network

Checking a concrete floor for tolerance.

A time bomb in floor tolerances? – Concrete Construction

Having Tolerance Compatibility Problems? For Construction Pros

Floor Flatness and Levelness Can Severely Affect Polished Concrete

Related Posts:

- Laying A Concrete Floor In A House

- Stained Concrete Floor Sealer

- Filling Holes In Concrete Floor Before Staining

- DIY Concrete Floor Tiles

- How Much Does It Cost To Seal Concrete Floors

- Concrete Floor Fire Rating

- Concrete Floor Issues

- Concrete Floor Faux Finish

- Latex Primer For Concrete Floors

- Concrete Floor Primer For Vinyl Tiles

Concrete Floor Tolerances: Everything You Need to Know

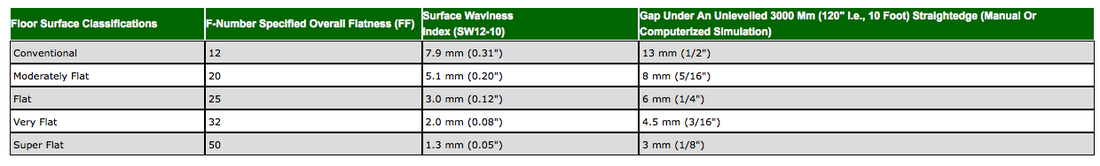

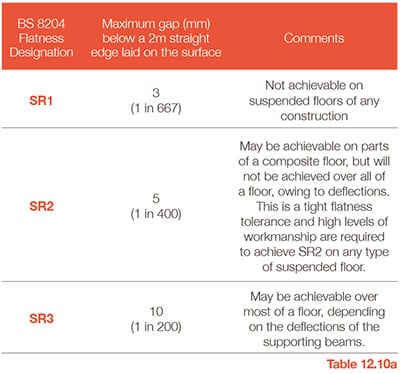

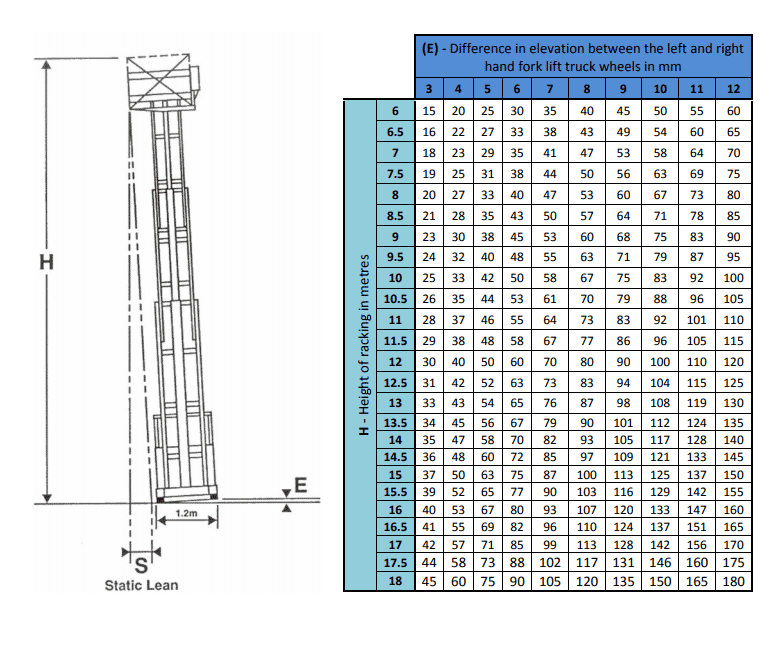

The quality of any concrete floor is determined by its ability to meet tolerances, which are standards for flatness and levelness. When a contractor pours the concrete, it must be within these exact specifications in order to ensure the best performance and longevity of the floor. In this article, we’ll discuss what these tolerances are, how they are measured, and why they are important. We will also provide answers to some frequently asked questions about concrete floor tolerances.

What Are Concrete Floor Tolerances?

Concrete floor tolerances are the standards used to determine whether a concrete floor is flat and level enough for use. A concrete floor must meet specific requirements in order to be considered suitable for use. These requirements vary depending on the type of application the concrete will be used for, but generally speaking, they all involve measurements of flatness and levelness.

How Are Concrete Floor Tolerances Measured?

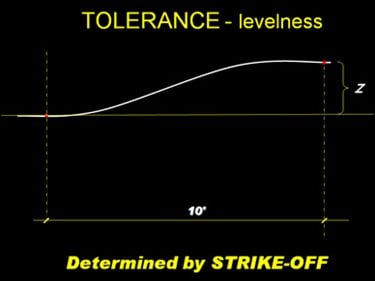

Concrete floor tolerances are measured using a variety of different tools and techniques. The most common tool is a laser level, which can measure both flatness and levelness quickly and accurately. Other tools such as straight-edges and spirit levels can also be used to measure tolerances. In addition, there are several methods that can be used to measure flatness and levelness, such as using a straight edge or a series of points along the surface of the concrete.

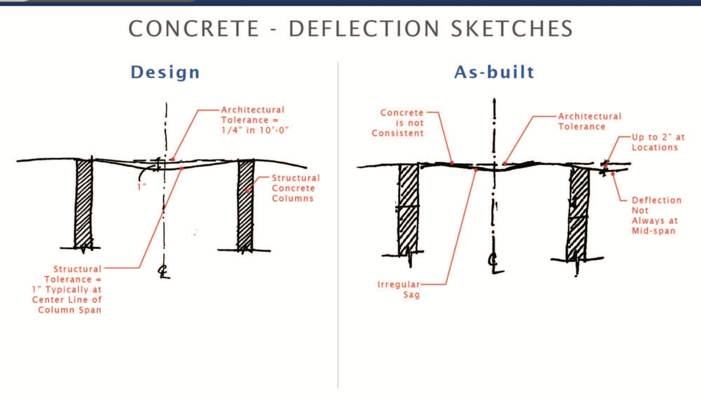

Why Are Concrete Floor Tolerances Important?

Concrete floor tolerances are important because they determine the overall quality of the finished product. If a concrete floor does not meet the required tolerances, it could cause problems such as uneven wear patterns or cracking over time due to poor settlement or improper curing processes. As such, it is essential that contractors follow proper procedures when pouring concrete floors in order to ensure that they meet all applicable tolerances.

FAQs About Concrete Floor Tolerances

Q: What is considered an acceptable tolerance for a concrete floor?

A: An acceptable tolerance for a concrete floor depends on the type of application it will be used for. Generally speaking, most residential applications require a flatness tolerance of 1/8 inch or less over 10 feet, while commercial applications typically require a tolerance of 1/4 inch or less over 10 feet. It is important to check with local building codes and regulations regarding acceptable tolerances for your particular application prior to beginning any work.

Q: How can I check if my concrete floor meets tolerance requirements?

A: The best way to check if your concrete floor meets tolerance requirements is with a laser level or other measuring device such as a straight edge or spirit level. A laser level will provide an accurate measurement of both flatness and levelness quickly and easily. If you do not have access to one of these devices, you can also use a series of points along the surface of the concrete in order to measure flattening and leveling.

Q: What happens if my concrete floor does not meet tolerance requirements?

A: If your concrete floor does not meet tolerance requirements, it may cause problems such as uneven wear patterns or cracking over time due to poor settlement or improper curing processes. In this case , you may need to take corrective action such as re-pouring or re-leveling the concrete in order to ensure that it meets all applicable tolerances.