First, you must decide whether the floor has a coating on it. It will require the bit of maintenance. The actual advantage is actually the durability that these varieties of floors have, together with the good looks of theirs. Manufacturing epoxy flooring covering items change the properties of theirs when subjected to humid surroundings.

Images about Duraflex Epoxy Floor Coatings

They’re not difficult to apply and often affordable. The good point about this particular type of coating is that you are able to blend it according to your needs. If the business of yours is contemplating floor plans for brand new design, or even desiring to renovate the old layout, epoxy floors can be extremely helpful to the plans of yours.

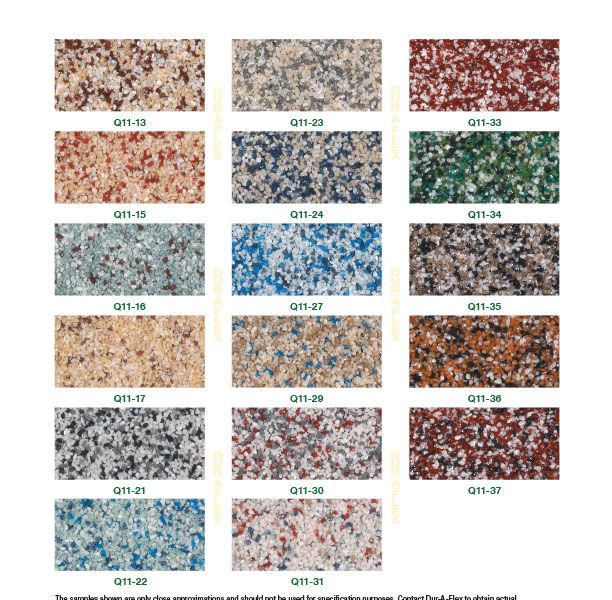

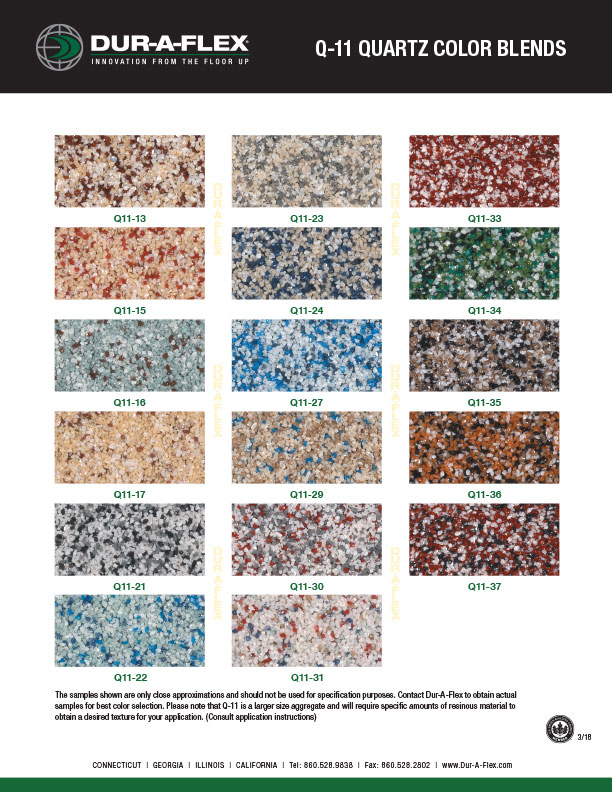

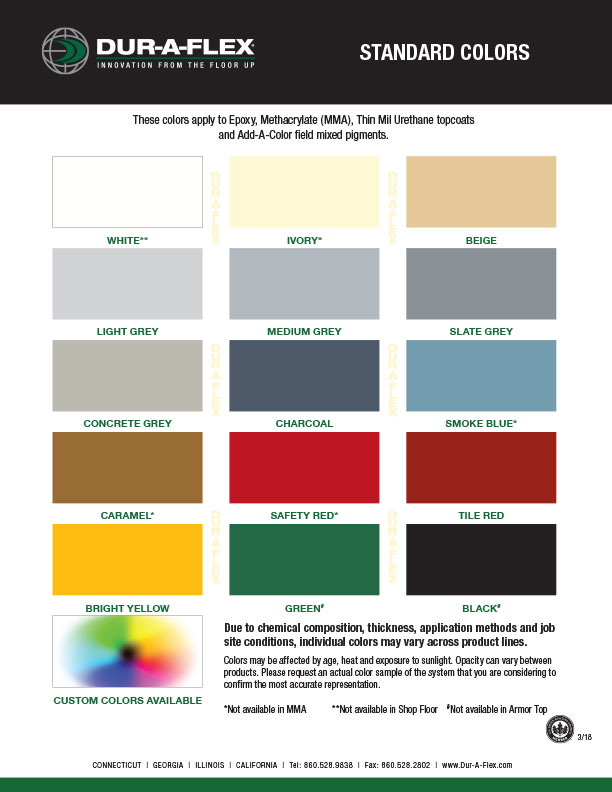

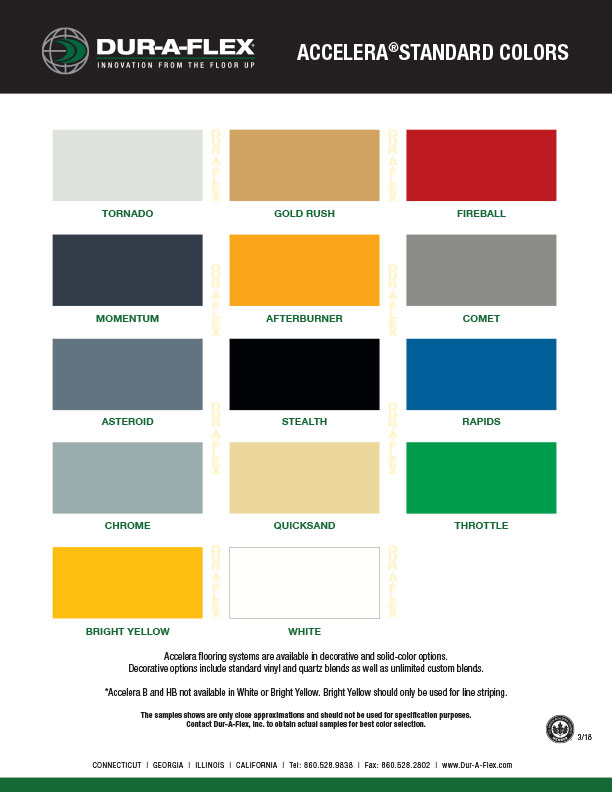

Color Charts for Epoxy Floors Associated Concrete Coatings

There are several epoxy goods with a wide variety of color options to choose from. The garages today aren’t only designed for parking the automobiles, but the serve various intents as well. More and more individuals are trying to follow epoxy floor paint to generate various rooms in their homes and businesses look better than before.

Hybri-Flex® EC – Dur-A-Flex

An epoxy flooring coating for the warehouse of yours is going to make the floor of yours in a position to endure the rough environments on which the usage of the fleet of yours of factory automobiles would normally harm the floor with no epoxy coating. Nonetheless, not all flooring is able to hold epoxy coating. The epoxy floor paints can be given the preferred color as per the person requirements.

Dur-A-Chip Vinyl Chip Flooring Dur-A-Flex

Dur-a-Flex Epoxy Systems – Flooring Concepts Inc.

Dur-A-Flex Epoxy – Advanced Surfaces Corporation

ACCELERA® HC – Dur-A-Flex

Color Charts for Epoxy Floors Associated Concrete Coatings

Dur-A-Flex Epoxy – Advanced Surfaces Corporation

Dur-a-Flex Epoxy Systems – Flooring Concepts Inc.

Color Charts for Epoxy Floors Associated Concrete Coatings

Dur-A-Quartz Epoxy Quartz Flooring Dur-A-Flex

Dur-A-Gard® ESD Static Dissipative Flooring Dur-A-Flex

Color Charts for Epoxy Floors Associated Concrete Coatings

Related Posts:

- Clear Epoxy Coating For Concrete Floors

- Harga Epoxy Floor Coating

- How Long For Epoxy Floor To Cure

- Rustoleum Epoxy Floor Paint Colors

- Quikrete Epoxy Floor Coating

- Steps To Epoxy Garage Floor

- DIY Epoxy Flooring Systems

- Epoxy Floor Paint Metallic

- Gloss Epoxy Floor

- Why Epoxy Your Garage Floor

Duraflex Epoxy Floor Coatings: Enhancing Durability and Aesthetics

Introduction:

Duraflex epoxy floor coatings have gained immense popularity in recent years due to their exceptional durability and aesthetic appeal. Whether it’s a residential garage, industrial warehouse, or commercial facility, these coatings provide a seamless and long-lasting flooring solution that can withstand heavy traffic, chemical spills, and impact. In this article, we will delve into the various aspects of Duraflex epoxy floor coatings, including their benefits, application process, maintenance requirements, and frequently asked questions.

I. Understanding Duraflex Epoxy Floor Coatings:

Duraflex epoxy floor coatings are a type of resinous flooring system that combines epoxy resins with various aggregates and pigments to create a highly durable and visually appealing surface. These coatings are commonly used in industrial settings but have also gained popularity for residential and commercial applications due to their versatility.

Duraflex offers a range of epoxy floor coating options, including solid color systems, decorative quartz systems, metallic systems, and more. Each system has its unique characteristics and benefits, making it suitable for different environments and design preferences.

FAQs:

1. What makes Duraflex epoxy floor coatings different from traditional flooring options?

Duraflex epoxy floor coatings offer several advantages over traditional flooring options. They are highly resistant to chemicals, stains, impact, abrasion, and UV rays. Additionally, they provide a seamless surface that is easy to clean and maintain.

2. Can Duraflex epoxy floor coatings enhance the aesthetics of my space?

Yes, Duraflex offers various decorative options like decorative quartz or metallic systems that can transform your space with stunning visual effects. These coatings come in a wide range of colors and patterns to suit any design aesthetic.

II. Advantages of Duraflex Epoxy Floor Coatings:

1. Exceptional Durability:

Duraflex epoxy floor coatings are renowned for their exceptional durability. The epoxy resins used in these coatings create a strong, chemical-resistant surface that can withstand heavy loads, foot traffic, and impact without cracking or chipping. This makes them ideal for high-traffic areas such as warehouses, factories, and garages.

2. Chemical and Stain Resistance:

One of the key advantages of Duraflex epoxy floor coatings is their resistance to chemicals and stains. They create a non-porous surface that repels spills and prevents them from seeping into the concrete substrate. This makes the cleaning process easier and helps maintain a hygienic environment in industries such as food processing, pharmaceuticals, and laboratories.

3. Seamless Installation:

Duraflex epoxy floor coatings offer a seamless installation process that ensures there are no joints or gaps in the flooring. This eliminates the risk of moisture penetration, bacterial growth, and other issues associated with traditional flooring options like tiles or vinyl sheets.

FAQs:

1. Can Duraflex epoxy floor coatings withstand heavy machinery or forklift traffic?

Yes, Duraflex epoxy floor coatings are designed to withstand heavy machinery, forklift traffic, and other industrial equipment without cracking or delamination. However, it’s crucial to consult with professionals to determine the appropriate thickness and aggregate selection based on your specific requirements.

2. Are Duraflex epoxy floor coatings suitable for outdoor applications?

While Duraflex epoxy floor coatings are primarily designed for indoor use due to their excellent chemical resistance and durability, they can also be used in covered outdoor areas. However, prolonged exposure to direct sunlight May cause the coating to fade or discolor over time. It is recommended to consult with professionals to determine the best coating system for outdoor applications based on your specific needs and conditions. 3. How long does it take to install Duraflex epoxy floor coatings?

The installation time for Duraflex epoxy floor coatings can vary depending on the size and complexity of the project. However, in general, the process can take anywhere from a few days to a couple of weeks. It is recommended to consult with professionals to get an accurate estimate for your specific project.

4. How do I clean and maintain Duraflex epoxy floor coatings?

Cleaning and maintaining Duraflex epoxy floor coatings is relatively easy. Regular sweeping or vacuuming to remove dirt and debris is recommended. For routine cleaning, a mild detergent or pH-neutral cleaner can be used with warm water and a soft mop or cloth. Avoid using harsh chemicals or abrasive cleaners as they can damage the coating. It is also important to promptly clean up any spills to prevent staining. Additionally, periodic resealing may be required to maintain the durability and appearance of the coating.

5. Can Duraflex epoxy floor coatings be applied over existing flooring?

In many cases, Duraflex epoxy floor coatings can be applied over existing flooring such as concrete, tile, or vinyl. However, proper surface preparation is crucial for ensuring adhesion and longevity of the coating. This may involve cleaning, repairing any cracks or damage, and applying a primer before applying the epoxy coating. It is recommended to consult with professionals to assess the condition of your existing flooring and determine if it is suitable for an epoxy coating.

6. What is the lifespan of Duraflex epoxy floor coatings?

The lifespan of Duraflex epoxy floor coatings can vary depending on factors such as traffic levels, maintenance practices, and environmental conditions. However, with proper installation and regular maintenance, these coatings can last for many years. It is recommended to consult with professionals to get an estimate of the expected lifespan for your specific project.