Floor epoxy covering protects your floor from atmospheric pollution, oxidation as well as chemical exposure. On the various other hand, the guarantee is typically more effective and it lasts longer compared to the water based version of its.. Epoxy floors are seamless, and there is no place for bacteria and other contaminants to multiply. It is likewise thermal and effect resistant.

Images about Duraflex Epoxy Flooring

You will get an extra benefit of protecting your concrete flooring from various other chemical compounds as well as oil stains to give an extra life to the untreated floor. Epoxy floors are extremely unwilling to surface injury with the inheriting properties of theirs.

Hybri-Flex® EC – Dur-A-Flex

Epoxy is very effective as concrete finishes, or top coats which complement the look of industrial floor finishes. This particular flooring type is not difficult to put in, and can be practiced by a professional or a motivated do-it-yourselfer by following a number of simple instructions. Many painters find that it is not user friendly for these reasons.

Dur-A-Chip Vinyl Chip Flooring Dur-A-Flex

You can even choose the look of the epoxy to match the look you would like to attain in your location. This means not merely is it going to not be harmed by chemical floor cleaners, but if a laboratory has epoxy flooring and some chemicals spill, it will not ruin the floor. Carpet stains readily and dirt and traps dust within.

Color Charts for Epoxy Floors Associated Concrete Coatings

Dur-a-Flex Epoxy Systems – Flooring Concepts Inc.

Dur-A-Flex Epoxy – Advanced Surfaces Corporation

ACCELERA® HC – Dur-A-Flex

Color Charts for Epoxy Floors Associated Concrete Coatings

Dur-A-Flex Epoxy – Advanced Surfaces Corporation

Dur-a-Flex Epoxy Systems – Flooring Concepts Inc.

Dur-A-Quartz Epoxy Quartz Flooring Dur-A-Flex

Dura Flex flake flooring – New England Epoxy Flooring Facebook

Dur-A-Quartz Epoxy Quartz Flooring Dur-A-Flex

Application Instructions for Dur-A-Flexu0027s Dur A Quartz

Related Posts:

- Epoxy Flooring Details

- Epoxy Floor Coating Thickness

- Epoxy Floor Paint Not Drying

- Cool Epoxy Floors

- Spray On Epoxy Flooring

- Epoxy Laundry Room Floor

- Garage Floor Epoxy Kit Colors

- Epoxy Flooring For Dog Kennels

- Epoxy Terrazzo Flooring Details

- How To Epoxy Your Garage Floor

Introduction to Duraflex Epoxy Flooring

Duraflex epoxy flooring is a revolutionary flooring system that combines the strength and durability of epoxy with the flexibility and resilience of rubber. It is designed to create a strong and long-lasting flooring solution for commercial, industrial, and residential applications. Duraflex epoxy flooring offers superior impact resistance, chemical resistance, and slip resistance. It is also non-porous, making it ideal for areas that are prone to water or other liquids. Additionally, Duraflex epoxy flooring provides a beautiful finish that will last for years. With its combination of features and benefits, Duraflex epoxy flooring is an excellent choice for any area where durability and performance are paramount.

Benefits of Duraflex Epoxy Flooring

Duraflex epoxy flooring has numerous benefits over traditional flooring materials. The most notable benefit is its strength and durability. Duraflex epoxy flooring is known for its superior impact resistance, making it an ideal choice for areas that require a hard-wearing surface such as warehouses or workshops. Additionally, Duraflex epoxy flooring is highly chemical resistant, making it ideal for areas that need protection from corrosive materials. The non-porous nature of the material also means that it won’t absorb liquids or other contaminants, making it an ideal choice for areas where hygiene and cleanliness are important. Finally, Duraflex epoxy flooring provides a beautiful finish that will last for years without needing regular maintenance or repair.

Installation Process for Duraflex Epoxy Flooring

Installing Duraflex epoxy flooring requires the use of special tools and techniques to ensure a successful installation. First, the area where the floor will be installed must be properly prepared by removing any existing debris or dirt. Next, the area should be leveled and primed before applying the Duraflex epoxy coating. Once the coating has been applied, it must be allowed to cure before the area can be used again. Finally, any necessary sealants or coatings should be applied in order to protect the surface from damage over time.

FAQs about Duraflex Epoxy Flooring

Q: What makes Duraflex epoxy flooring so durable?

A: Duraflex epoxy flooring is extremely durable due to its combination of chemicals which create a strong bond between the substrate and the coating material. Additionally, it has superior impact resistance which makes it an ideal choice for areas that require a hard-wearing surface such as warehouses or workshops.

Q: How long does it take to install Duraflex epoxy flooring?

A: The time required to install Duraflex epoxy flooring depends on several factors such as the size of the area being covered and any preparation work necessary prior to applying the coating material. Generally speaking, however, installation can take anywhere from one day up to several days depending on how much preparation work needs to be done beforehand.

Q: Does Duraflex epoxy flooring require regular maintenance?

A: No, Duraflex epoxy flooring requires very little maintenance once it has been installed properly. It is a non-porous material which means that it won’t Absorb liquids or other contaminants, so it won’t need to be cleaned or sealed regularly. Additionally, its superior impact resistance means that it won’t need to be repaired or replaced as often as traditional flooring materials.

What is the cost of Duraflex epoxy flooring?

The cost of Duraflex epoxy flooring depends on the size of the area to be covered, the complexity of the installation, and other factors. Contact a local flooring expert for an accurate quote.

What are the advantages of Duraflex epoxy flooring?

1. Durability: Duraflex epoxy flooring is extremely durable and can withstand heavy foot traffic and machinery, making it ideal for industrial, commercial and residential applications.

2. Chemical Resistance: Duraflex epoxy flooring is highly resistant to oil, grease, gasoline and other chemicals. This makes it suitable for use in automotive garages and other areas with the potential for spills or frequent cleanups.

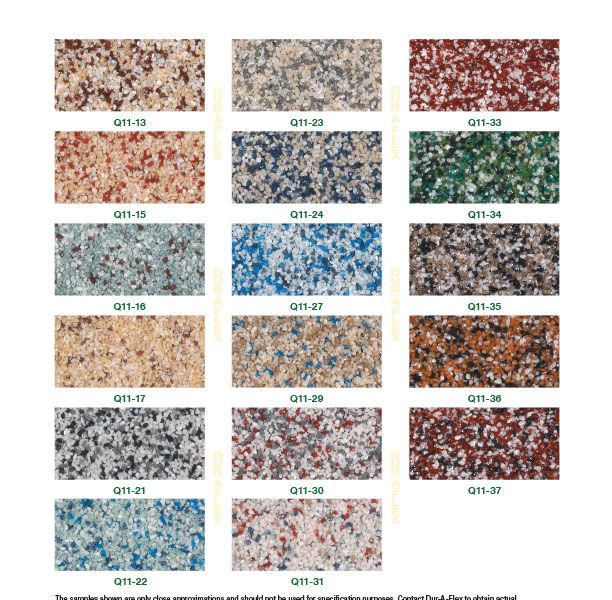

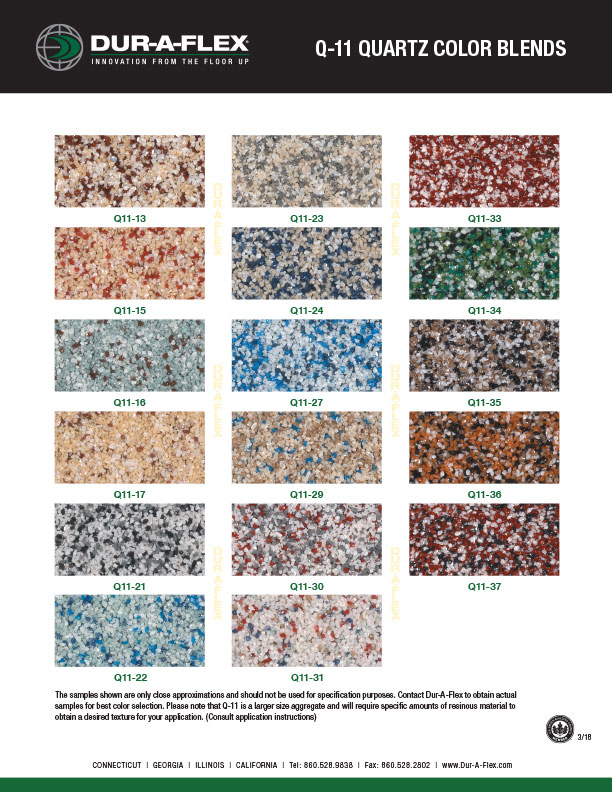

3. Aesthetic Appeal: Duraflex epoxy flooring offers a wide range of color options that can be used to create beautiful designs and patterns. The glossy finish adds an elegant touch to any space.

4. Easy Maintenance: Since Duraflex epoxy flooring is resistant to staining and damage, it requires minimal care and maintenance. Regular sweeping and mopping is usually enough to keep the surface clean.

5. Cost-Effective: Installing Duraflex epoxy flooring is relatively inexpensive compared to other types of flooring materials, making it an economical choice for many homeowners or business owners.

What is the cost of Duraflex epoxy flooring?

The cost of Duraflex epoxy flooring varies depending on the size of the area and the type of coating being applied. Generally speaking, the average cost for a basic 200 square foot area is between $2,500 and $3,500.