With many selections of hardwood floors offered, consumers are frequently confused about the make up of wood floors resulting in getting a floor which doesn’t fit into an allotted financial position or installation not designed for the intended use. Lots of offshore manufactured products will say they’ve lightweight aluminum oxide in them but in fact do not.

Images about Engineered Hardwood Flooring Hardness Scale

These pieces need to be laid in the same track as the panel rows of yours. Solid hardwood flooring is milled from a single portion of lumber, and it is readily available both unfinished and prefinished. purchasing and Installation of a wood flooring not created for a certain function will frequently lead to loss and replacement of expenditures of funds earlier applied.

Janka Hardness Scale – Superior Flooring

The first element that a person notice when they enter a particular home is the floor. If the retailer offering you flooring does not use a moisture meter and will take a look at the moisture for you next I would recommend you run. Strong hardwood flooring demands special care to keep their look and luster. Many hardwoods these days are sent pre finished.

Janka Scale Musolfu0027s Wood Flooring

What is Janka Hardness Rating? Pinnacle Floors

The Janka Scale Blog – KT Hardwoods, Inc.

Hardwood Flooring Hardness Guide Janka Hardness Scale Bamboo

Hardness Chart Reserve Hardwood Flooring

Hardwood Flooring Buying Guide

Janka Wood Hardness Chart

Janka Scale A Step Above Flooring u0026 Installation, Inc.

The Janka Hardness Scale – Not just a number u2013 Gaylord Flooring

Related Posts:

- Hardwood Flooring DIY Cost

- Hardwood Floor Scratches From Dogs

- Best Way To Install Engineered Hardwood Flooring On Concrete

- Engineered Hardwood Flooring Photos

- What Is Bamboo Hardwood Flooring

- Hardwood Floor Padding Cost

- Usfloors Exotic Locking Bamboo Hardwood Flooring

- Hardwood Flooring Black Walnut

- Black Locust Hardwood Flooring

- Hardwood Flooring Ideas Photos

Engineered Hardwood Flooring Hardness Scale: An Overview

Choosing the right flooring for a home can be an overwhelming task. With so many brands and types of flooring available, it can be difficult to know which type is best for the customer’s needs. One such option is engineered hardwood flooring, which is designed to be more durable than traditional hardwood floors. To help buyers make the right decision, it’s important to understand the engineered hardwood flooring hardness scale and how it applies to their purchase.

What is Engineered Hardwood Flooring?

Engineered hardwood flooring is made from three or more layers of wood that are bonded together under heat and pressure. The top layer is typically composed of real hardwood, while the other layers are composed of plywood or high-density fiberboard (HDF). This construction makes engineered hardwood flooring more resistant to changes in temperature and humidity than traditional hardwood floors. It also makes them easier to install, as they can usually be floated on top of an existing subfloor.

What is the Engineered Hardwood Flooring Hardness Scale?

The engineered hardwood flooring hardness scale is a measure of how resistant the product is to dents and scratches. The scale ranges from 1-6, with 6 being the hardest and most resistant to wear and tear. The higher the number on the scale, the harder and more resilient the product will be over time. Each manufacturer will assign a hardness rating to their particular product, so it’s important to check this rating before making a purchase.

What Are The Benefits Of An Engineered Hardwood Floor With A High Hardness Rating?

Engineered hardwoods with a higher hardness rating offer several benefits over those with a lower rating. They are highly resistant to scratches and dents, making them ideal for areas with heavy foot traffic or pets. They are also less likely to fade over time due to exposure to sunlight or extreme temperatures, making them great for homes in sunny climates or with large windows that allow in lots of natural light. Finally, they tend to retain their original shape better than softer options, meaning they won’t warp or buckle as easily when exposed to moisture or high humidity levels.

Why Might Someone Choose An Engineered Hardwood Floor With A Lower Hardness Rating?

While engineered hardwoods with a higher hardness rating offer several benefits, they can also be more expensive than those with a lower rating. For those who are on a tight budget but still want an attractive flooring option, there may be advantages to choosing one with a lower hardness rating that offers good value for money without sacrificing too much in terms of durability and longevity. Furthermore, softer options may be more comfortable underfoot than harder options, making them good choices for bedrooms or other areas where people spend a lot of time standing or sitting on the floor.

Frequently Asked Questions About The Engineered Hardwood Flooring Hardness Scale

Q: How Is The Hardness Rating Determined?

A: The hardness rating is determined by testing samples of the product in a laboratory setting using specialized equipment that measures its resistance to indentation under pressure. This testing is performed according to industry standards set By the American National Standards Institute (ANSI).

What is the Janka scale for engineered hardwood flooring?

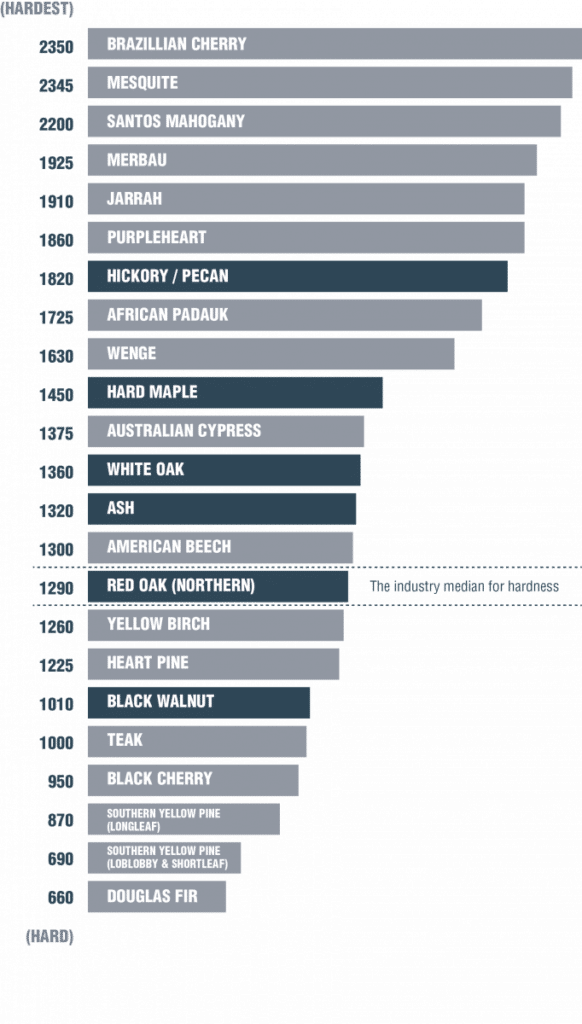

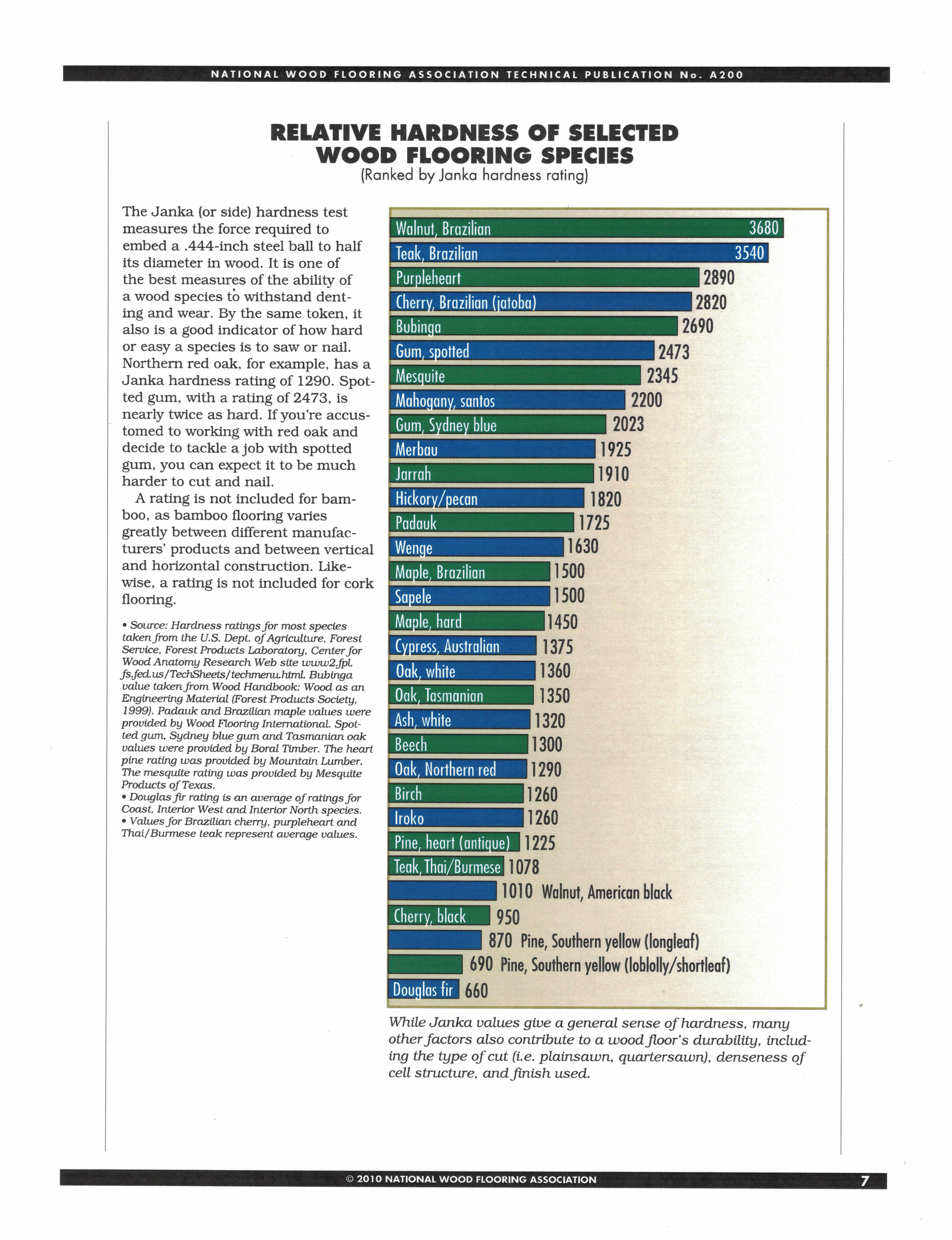

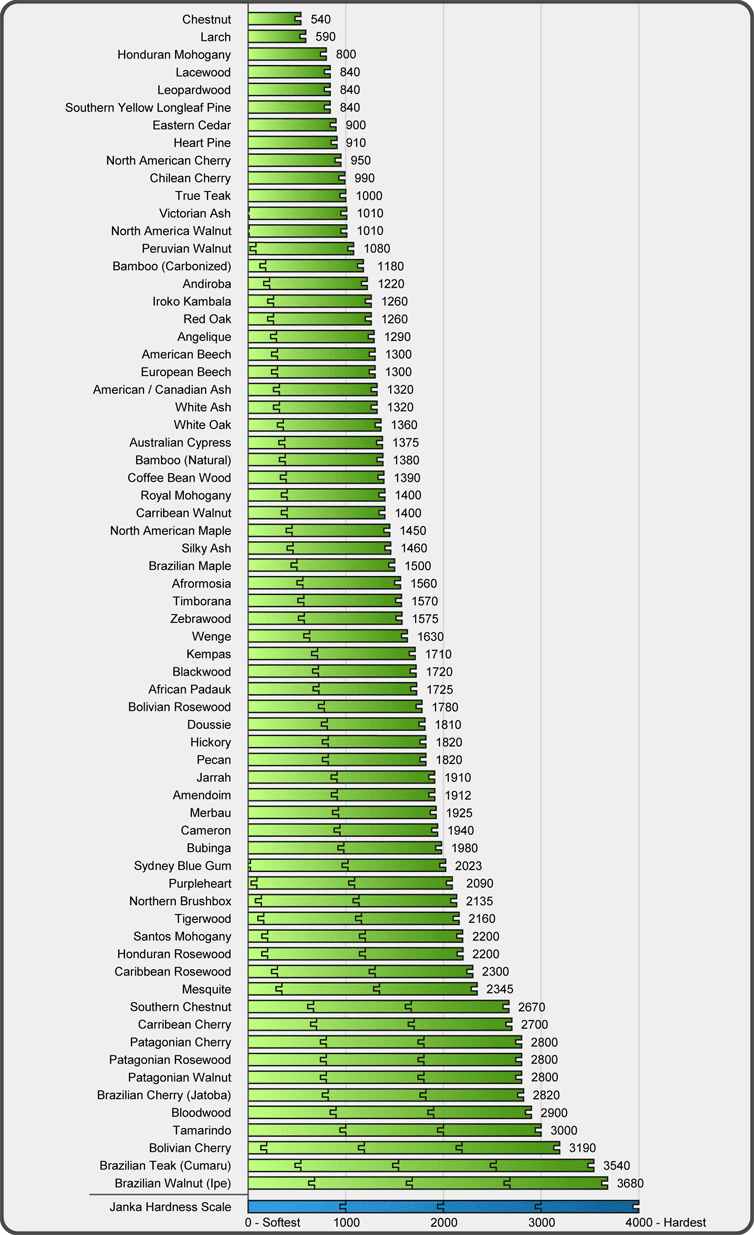

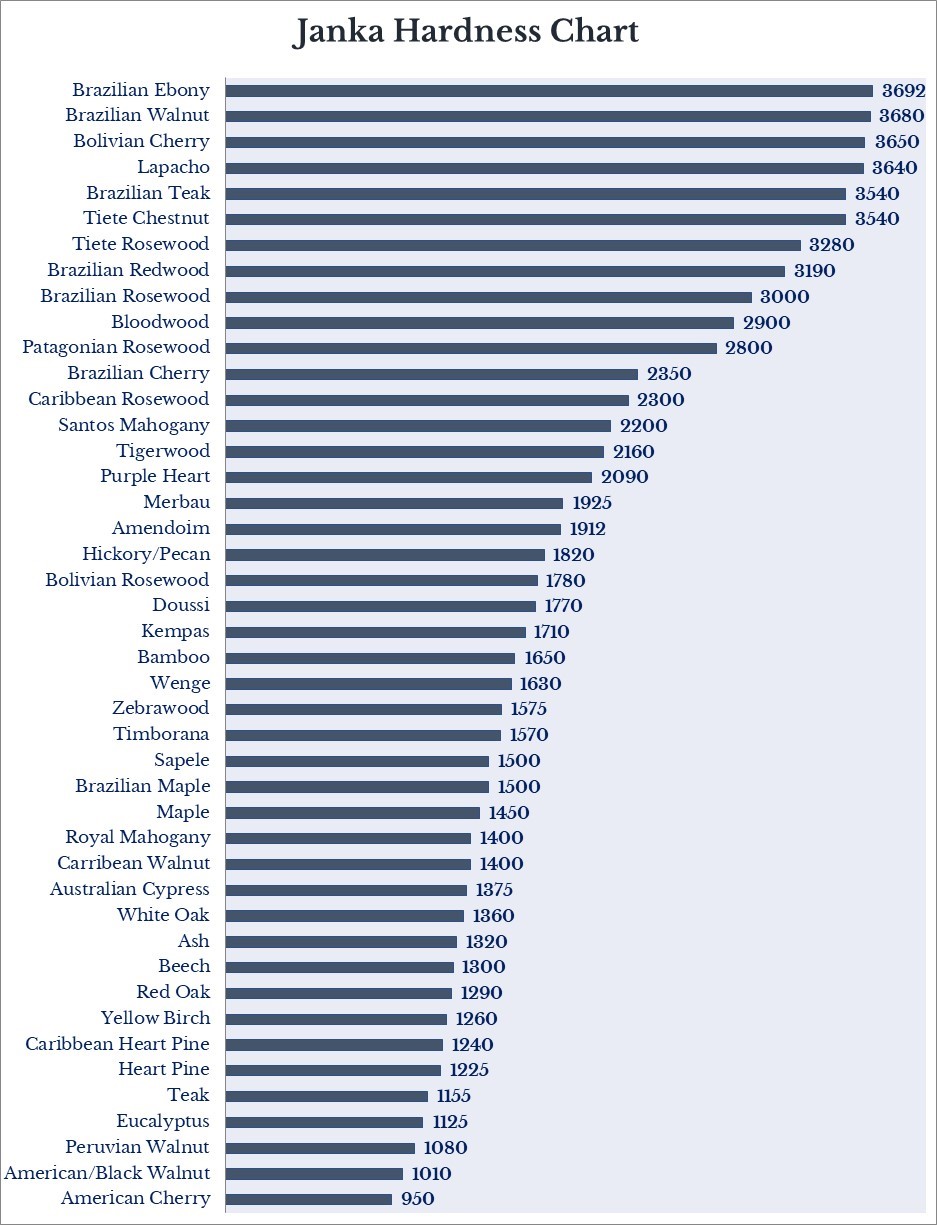

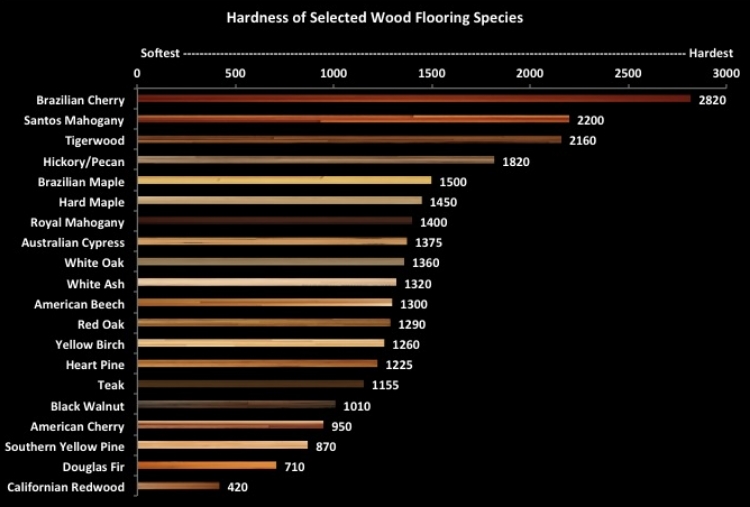

The Janka scale is used to measure the hardness of a wood species. It measures the amount of force required to embed a .444 inch steel ball into the wood by half its diameter. The higher the number, the harder the flooring material. For engineered hardwood flooring, the Janka rating typically ranges from 1,000-3,000 depending on the species and construction of the product.

What is the difference between solid and engineered hardwood flooring?

Solid hardwood flooring is made from a single piece of wood and is usually 3/4 inch thick. This type of flooring can be sanded and refinished multiple times and is the most durable option. Engineered hardwood flooring is made with layers of real wood that are bonded together with adhesives. This type of flooring can vary in thickness, but is generally thinner than solid hardwood flooring. Engineered wood flooring is more dimensionally stable than solid hardwood, making it better suited for areas with high humidity or temperature changes. It cannot be sanded or refinished as many times as solid hardwood, but it typically has a longer lifespan than laminate or vinyl flooring.

What are the pros and cons of solid and engineered hardwood flooring?

Pros of Solid Hardwood Flooring:

– Solid hardwood flooring is a timeless and classic option that adds beauty and value to any home.

– It is durable and can last for generations if properly cared for.

– It is easy to repair and refinish.

– It can be sanded down and refinished multiple times over its lifetime.

Cons of Solid Hardwood Flooring:

– It is expensive and difficult to install.

– It can be susceptible to water damage, staining, and warping if exposed to too much moisture.

– It may require professional installation.

Pros of Engineered Hardwood Flooring:

– Engineered hardwood flooring is more affordable than solid hardwood due to its construction.

– It is resistant to moisture, making it an ideal choice for rooms prone to spills or high humidity levels.

– It is easier to install than solid hardwood, as it can be installed as a floating floor or glued down.

– It comes in a variety of colors, textures, and styles, making it an attractive choice for many homeowners.

Cons of Engineered Hardwood Flooring:

– It cannot be sanded or refinished like solid hardwood, meaning it must be replaced when it begins to show signs of wear and tear.

– Its lifespan is much shorter than that of solid hardwood, typically ranging from 10 to 20 years depending on usage and care.

– Its construction makes it more susceptible to damage from scratches or dents if not properly maintained.