Epoxy coat is also of low porosity and is chemical resistant. The surface is very simple to keep and it's strong to sustain abusive use by commercial or heavy-traffic scale operations. You will eventually realize that epoxy flooring is quite convenient since it meets most of the manufacturing needs. These elements assault industrial floors frequently in the course of daily operations.

Images about Epoxy Garage Floor Crack Filler

Poly urea pains ordinarily cost up to four times the amount of epoxy flooring and homeowners or maybe business owners do not see any advantages of from the increased price. The fact is that this only comes in a single color, tan, but it may be used to create labels often by itself or even along with other epoxy floorings.

Whatu0027s Cracking? Dealing with Cracks in Epoxy Coatings – Garage

These are the reasons that floor epoxy coatings are used in numerous places like institutions, schools, government facilities, office buildings, showrooms, factories, warehouses, kennels, garage, and hospitals demanding heavy-duty flooring needs. It's not difficult to apply hence preserving on labor. Several of the most desired shades for garage flooring are beige, charcoal, taupe, and grey.

Concrete crack repair and filler 100% Solid Epoxy Filler

The color choices are only limited by the company which offers them. Many of these characteristics provide longer durability of surfaces. Applying your very own epoxy flooring to a commercial building or maybe an area in your home could be easier than expected. Higher quality epoxy resin is actually used to update surfaces, obtain colored effects, protect floor surfaces against corrosion, and achieve a water tight effect.

Garage Epoxy Flooring Concrete Repair Resurfacing

How To Repair a Heavily Damaged Garage Floor Using Epoxy

Garage Floor Crack Repair 101 (Plus When to DIY u0026 When to Call a Pro)

CRACK REPAIR EPOXY PUTTY

DIY Epoxy Concrete Crack Repair – What I use – How I Repair Concrete

How to Repair Garage Floor Cracks and Pitting All Garage Floors

Concrete Slab Crack Repair Instructional Video (Previous Version)

Foundation Crack Repair in 8 Steps – This Old House

/cdn.vox-cdn.com/uploads/chorus_asset/file/19495119/00_concrete_xl.jpg)

How to Repair Concrete Floor Crack Repairs Repair Garage Floor

EPOXY FLOOR HACKS. Epoxy Floor Caulking Before Application. Tips

DIY Epoxy Garage Floor Coating Repair – Casper, WY

Related Posts:

- Sika Epoxy Floor Paint

- Epoxy Flooring Cost Per Sq Ft

- Best Way To Clean Epoxy Garage Floor

- Epoxy Flooring Commercial Kitchen

- Behr Garage Floor Epoxy Paint

- Mma Flooring Vs Epoxy

- Epoxy Resin Flooring Training

- DIY Epoxy Floor Kits

- Commercial Grade Floor Epoxy

- Epoxy Vs Urethane Floor Coating

Title: Epoxy Garage Floor Crack Filler: The Ultimate Solution for a Flawless Garage Floor

Introduction:

A garage floor crack can be a frustrating and unsightly problem for any homeowner. Not only does it compromise the overall appearance of your garage, but it can also lead to further damage if left untreated. Fortunately, with the advent of epoxy garage floor crack fillers, you no longer have to worry about these issues. In this article, we will delve into the world of epoxy garage floor crack fillers, discussing their benefits, application process, frequently asked questions, and more.

I. Understanding Epoxy Garage Floor Crack Fillers:

Epoxy garage floor crack fillers are specially formulated products designed to repair and seal cracks in your garage floor effectively. Made from a combination of epoxy resin and hardeners, these fillers provide a durable and long-lasting solution that not only prevents further damage but also enhances the overall appearance of your garage.

FAQs:

Q1: What causes cracks in a garage floor?

A1: Cracks in a garage floor can be caused by various factors such as settlement, improper installation, temperature fluctuations, or heavy vehicle loads. It is essential to address the underlying cause before applying an epoxy crack filler.

Q2: Why should I use an epoxy crack filler instead of traditional alternatives?

A2: Epoxy crack fillers offer several advantages over traditional alternatives such as cement or polyurethane-based fillers. They provide superior strength and durability, excellent adhesion properties, resistance to chemicals and moisture, and are less likely to shrink or crack over time.

II. Benefits of Epoxy Garage Floor Crack Fillers:

1. Enhanced Durability:

Epoxy garage floor crack fillers offer exceptional durability, making them an ideal choice for high-traffic areas like garages. Once cured, these fillers create a strong bond with your concrete surface that can withstand heavy vehicle loads and resist cracking, ensuring longevity.

2. Improved Aesthetics:

Cracks in your garage floor can be an eyesore, diminishing the overall appeal of your space. Epoxy crack fillers provide a seamless finish, effectively hiding any signs of damage. Furthermore, they are available in various colors and finishes, allowing you to customize your garage floor according to your preferences.

3. Resistance to Chemicals and Moisture:

Garages are often exposed to chemicals such as oil, gasoline, and harsh cleaning agents. Epoxy garage floor crack fillers offer excellent resistance to chemicals, ensuring that spills and leaks do not cause further damage to your floor. Additionally, these fillers create a moisture barrier that prevents water penetration, reducing the risk of mold or mildew growth.

FAQs:

Q1: Can I apply epoxy crack filler on a severely damaged garage floor?

A1: While epoxy crack fillers are effective for minor cracks and surface imperfections, severely damaged floors may require more extensive repair work. Consult a professional if you suspect significant structural issues with your garage floor.

Q2: How long does it take for epoxy garage floor crack fillers to cure?

A2: The curing time for epoxy crack fillers varies depending on the specific product and environmental conditions. Typically, it takes around 24-48 hours for epoxy fillers to fully cure before you can resume normal use of your garage.

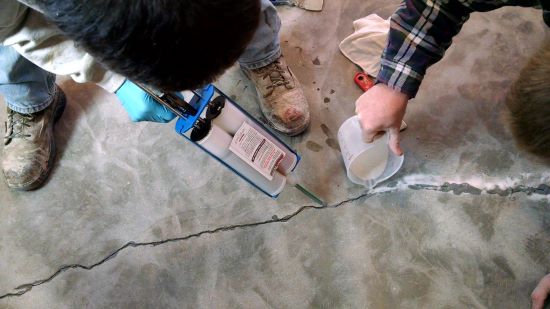

III. Application Process for Epoxy Garage Floor Crack Fillers:

1. Preparation:

Before applying an epoxy garage floor crack filler, it Is important to prepare the surface properly. Start by cleaning the floor thoroughly, removing any dirt, dust, or debris. You can use a broom, vacuum, or pressure washer for this step. Additionally, make sure to remove any loose concrete or old filler material from the cracks.

2. Crack Repair:

For best results, it is recommended to widen the cracks slightly using a chisel or angle grinder. This will help create a better bond between the filler and the concrete surface. Use a wire brush to clean out any remaining debris from the cracks.

3. Mixing and Application:

Follow the manufacturer’s instructions for mixing the epoxy crack filler. Typically, you will need to mix equal parts of resin and hardener until they are thoroughly combined. Use a putty knife or trowel to apply the mixed filler into the cracks, ensuring that it completely fills the voids. Smooth out the surface of the filler with the putty knife or trowel.

4. Curing:

Allow the epoxy crack filler to cure for the recommended time stated by the manufacturer. During this period, it is important to avoid walking or driving on the filled cracks to ensure proper bonding and hardening.

5. Finishing Touches:

Once the epoxy crack filler has cured, you can sand down any excess material using sandpaper or a sander to achieve a smooth finish. If desired, you can also apply a topcoat or sealer to further enhance the appearance and protection of your garage floor.

Remember to always read and follow the specific instructions provided by the manufacturer of your chosen epoxy crack filler product for best results and safety precautions.