Nevertheless, seamless epoxy flooring gives you many benefits in a cost effective way. Concrete is actually porous which enables it to absorb dirt, salt, oils and chemicals, making it challenging to wash the concrete floors properly. It remains to become probably the most sought-after coatings methods that meet any sort of coatings application requirements. There is no problems with concrete dust, as well as cleaning is additionally easy.

Images about Epoxy Resin Flooring System

The floors are waterproof and prevent water from assaulting the substrate beneath. Even and appealing floor surfaces with epoxy polished concrete offer an excellent visual appeal. This can help the home owner hold the surfacing that perfectly complements the home of his or perhaps office interiors. Available in a rainbow of styles, these flecks, inside conjunction with the basic coats, give epoxy floor surfaces a burst of hue.

What is Resinous Flooring?

Rather than thinking about swapping out an old concrete floor, more individuals are trying to follow epoxy floor paint to come up with the floor look and perform better than it ever before had before. In addition, they are able to be cleansed readily and provide exceptional value for money.

Epoxy Flooring Systems wsmepoxyfloors

It won't impact the appearance of the floor or could it corrode the surface. Moreover, you should also think about the air temperature in the garage of yours. Even if the family of yours is actually acknowledged for their rough and tumble behavior, epoxy flooring won't allow you to down with the outstanding overall performance of its.

The Ultimate Introduction to Epoxy Flooring Flowcrete

Epoxy Resin Terrazzo Resinous Flooring – TERRAZZCO

Concrete Coatings Garage Floor Coating Penntek Coatings

Epoxy/Urethane floor coating – Material Handling 24/7

Broadcast vs Troweled Quartz Systems: Which is Right For Your Job

Epoxy Flooring Part 3: Benefits to Your Business All Things Flooring

6009 Epoxy Floor Coating Industrial u0026 Commercial Low Temp 35°F 100% Solids Quick Cure

Resin Flooring Spectra Contract Flooring

Chip Flooring Systems – Resinwerks

Seamless Epoxy Flooring Installation

NOVOL NOVOFLOOR – Anti-slip epoxy floor system

Related Posts:

- Rust Oleum Epoxyshield Premium Clear Floor Coating Kit

- Mma Flooring Vs Epoxy

- Epoxy Floor Leveler Self Leveling

- Epoxy Resin Floor Filler

- Epoxy Resin Floor Thickness

- Grinding Floor For Epoxy

- Basement Epoxy Floor Coating Reviews

- Jotun Epoxy Floor Coating

- Metallic Epoxy Bathroom Floor

- Fosroc Self Leveling Epoxy Flooring

Introduction

Epoxy resin flooring systems are a great choice for commercial and industrial applications. They provide a durable, seamless surface that is easy to clean and maintain. An epoxy resin flooring system also has excellent resistance to chemicals, oils, and other liquids, making it ideal for areas where these types of liquids are present. In addition, epoxy resin flooring systems are available in a variety of colors and textures, allowing you to customize the look of your floor to suit any environment. In this article, we’ll discuss the benefits of epoxy resin flooring, the installation process, and common FAQs about this type of flooring system.

Benefits of Epoxy Resin Flooring Systems

Epoxy resin flooring systems offer a number of benefits over other types of flooring systems. For starters, they provide a seamless surface that is easy to clean and maintain. The smooth finish also makes them slip resistant, which is important in areas where liquids may be present.

Epoxy resin flooring systems are also extremely durable. They can withstand heavy foot traffic and resist scratches from furniture or equipment. In addition, they have excellent resistance to oils, chemicals, and other liquids. This makes them ideal for industrial or commercial applications where these types of liquids may be present. Furthermore, epoxy resin flooring systems come in a variety of colors and textures, allowing you to customize the look of your floors to suit any environment.

Installation Process

The installation process for an epoxy resin flooring system typically consists of several steps:

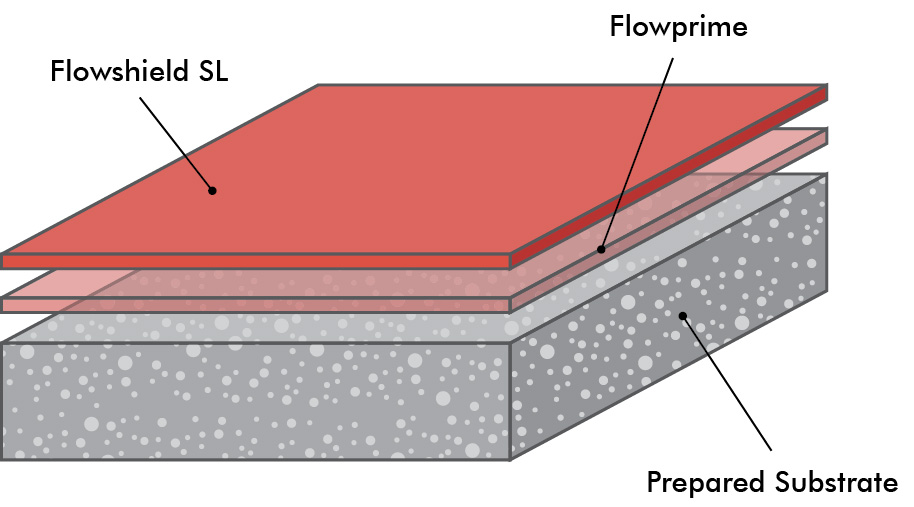

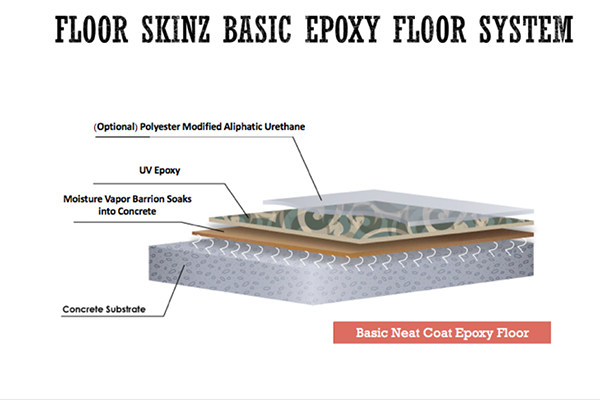

1) Preparing the Subfloor: The first step in the installation process is preparing the subfloor. This involves removing any existing debris or coatings that may be present on the substrate. Additionally, any cracks or holes should be filled with a suitable patch material prior to applying the epoxy primer/basecoat.

2) Applying the Primer/Basecoat: After the subfloor has been prepared, the primer/basecoat should be applied. This product helps create an even base layer for subsequent coats of epoxy resin flooring material. It should be applied according to manufacturer’s instructions in order to ensure proper adhesion and coverage.

3) Applying Topcoats: After the primer/basecoat has been applied and allowed to cure properly, multiple coats of topcoat should be applied in order to create a durable finish. Depending on the specific product being used, different topcoats may need to be applied in order to achieve optimal results.

4) Finishing Touches: Once all coats have been applied and have cured properly, any finishing touches such as edging or striping can be done in order to complete the project.

FAQs about Epoxy Resin Flooring Systems

Q: What are some common uses for epoxy resin flooring systems?

A: Epoxy resin flooring systems are commonly used in commercial and industrial settings due to their durability and excellent resistance to chemicals, oils, and other liquids. Additionally, they can also be used in residential settings as an attractive alternative to traditional tile or wood floors.

Q: How long does an epoxy resin flooring system last?

A: On average, an epoxy resin flooring system can last up 10 years or more with Proper maintenance and care.

What is the cost of epoxy resin flooring?

The cost of epoxy resin flooring can vary widely depending on the complexity of the project, the size of the space, and other factors. On average, you can expect to pay anywhere from $4 to $15 per square foot for the materials and labor.What are the benefits of epoxy resin flooring?

1. Durability: Epoxy resin flooring is highly durable and can withstand heavy foot traffic, abrasion, and impacts from dropped objects. It is also resistant to most chemicals, making it ideal for industrial environments.2. Safety: Epoxy resin floors are non-slip and have a high coefficient of friction, making them safer than other types of flooring. This makes them ideal for areas where slip hazards could present a safety risk.

3. Low Maintenance: Epoxy resin flooring requires minimal maintenance and cleaning. It is easy to clean with a damp mop or broom, and it is resistant to most chemicals, so spills can be easily cleaned up without causing damage to the surface.

4. Aesthetic Appeal: Epoxy resin flooring comes in many colors and designs, allowing you to customize the look of your space. It can also be used to create interesting patterns or logos on the surface of the floor.

5. Cost: While installation costs may vary depending on the size of the area being covered and the complexity of the design, epoxy resins offer a cost-effective solution that lasts for years with minimal maintenance costs.

What are the drawbacks of epoxy resin flooring?

1. Expensive: Epoxy flooring is more expensive than traditional flooring options like carpet, tile, and hardwood due to the labor involved in installation and the cost of materials.2. Difficult to Install: Installing epoxy flooring requires a great deal of skill and experience. If not installed properly, it can crack or bubble up over time, which could lead to costly repairs down the road.

3. Slippery Surface: Although some types of epoxy are designed to be slip resistant, it can still be slippery when wet or if there is a build-up of dust or dirt on the surface.

4. Not Suitable for All Environments: Epoxy flooring can be damaged by certain chemicals, so it might not be suitable for facilities that use certain hazardous chemcials (such as oil refineries).