The majority of the individuals are opting for epoxy flooring usually for garage floors. The reason for the differing schools of thought lay in the car maker's instructions as well as the way in which the contractors make use of the item and their encounters with this. You ought to begin browsing to find the best choice. Epoxy floors coatings are available in a number of styles.

Images about Epoxy Terrazzo Flooring Installation

Epoxy is able to withstand even the heaviest of vehicle consumption, like forklifts along with other heavy warehouse equipment. This's perfect for warehouses, garages, manufacturing plants along with other high traffic areas. In residential homes most homeowners used epoxy flooring coating for their garages if the flooring is made of concrete. If in need for an even more sturdy combination, then one can simply change it and have the mixture which they would like.

Cheminert Terrazzo – DEX-O-TEX

The primary idea of concrete floor epoxy covering is to provide flooring solutions for your whole flooring problems such as wet and slippery surfaces as well as surfaces hurt by synthetic spillage. Epoxy floor surfaces are actually favored in industrial environments as they give a bit longer life to an untreated flooring as well as help stop the floor from obtaining spoilt by oil as well as chemical discolorations.

Details u0026 Drawings

The epoxy floors coatings are often used over concrete floors to supply best binding benefits and aesthetically appealing surfaces. Epoxy floors can withstand weight and pressure high. Probably the most commonly used type of epoxy flooring for the place is actually the water used version as it probably the simplest of them to utilize as it's made up both of the primer and/or topcoat and it is absolutely ideal for using in garage parts.

Epoxy Terrazzo Flooring Systems u2013 Are They Right for Your Project?

Epoxy Resin Terrazzo Resinous Flooring – TERRAZZCO

Epoxy Terrazzo VS Cement Terrazzo: The Pros u0026 Cons – Written in Stone

Epoxy Resin Terrazzo Resinous Flooring – TERRAZZCO

Epoxy Terrazzo u2013 The Venice Art Terrazzo Company

Sustainable Flooring – Low VOC Terrazzo for Commercial Buildings

What are the Differences Between Cementitious and Epoxy Terrazzo

Epoxy Terrazzo Flooring Ideas u0026 Supplies – Concrete Network

Thin Set Epoxy Terrazzo vs Cementitious Terrazzo

Flooring – Terrazzo – Archtoolbox

Terrazzo Techniques: Thin-Set Terrazzo Topping over Existing Terrazzo

Related Posts:

- Quikrete Epoxy Flooring

- Ct Epoxy Floor Systems

- Epoxy Shield Industrial Floor Coating

- Fixing Garage Floor Cracks Epoxy

- Epoxy Flooring Systems Grand Forks

- Clear Epoxy Resin Floor Coating

- Epoxy Floor Finish On Wood

- Fosroc Epoxy Flooring

- Clear Epoxy Floor Finish

- 1 Part Epoxy Floor Paint

Epoxy Terrazzo Flooring Installation: Creating Stunning and Durable Surfaces

Introduction:

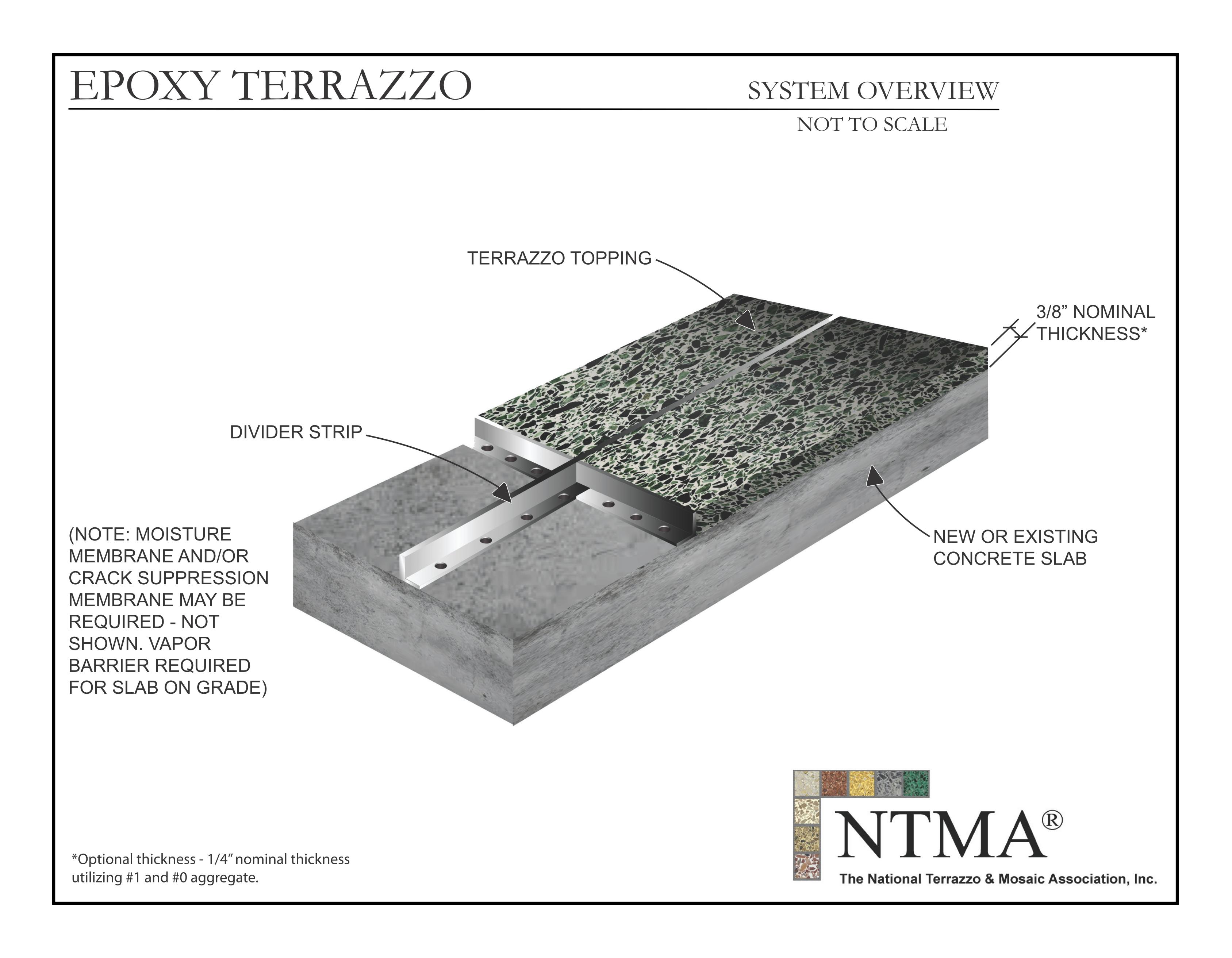

Epoxy terrazzo flooring is gaining popularity as a versatile and aesthetically pleasing option for both residential and commercial spaces. This flooring system combines the durability of epoxy resin with the beauty of decorative aggregates, resulting in a stunning and long-lasting surface. In this article, we will delve into the details of epoxy terrazzo flooring installation, exploring each step involved in creating these remarkable floors.

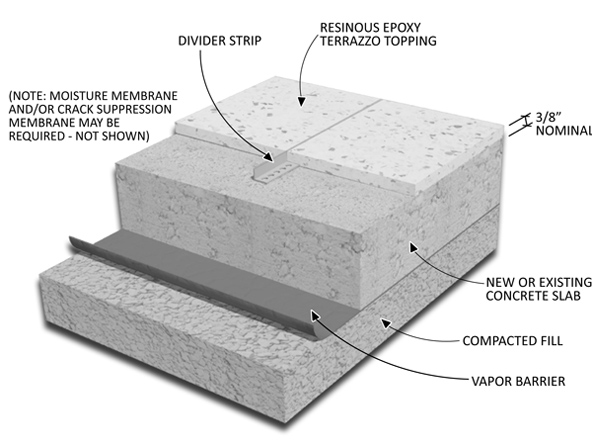

1. Surface Preparation:

Before installing epoxy terrazzo flooring, proper surface preparation is crucial to ensure optimal adhesion and longevity. The existing substrate must be clean, dry, and free from any contaminants such as oil, grease, or dust. Depending on the condition of the substrate, it may require grinding or shot blasting to remove any coatings or unevenness.

FAQs:

Q: Can epoxy terrazzo be installed over existing tile or hardwood floors?

A: Yes, epoxy terrazzo can be installed over various existing surfaces, including tile and hardwood floors. However, proper surface preparation is essential to ensure adhesion.

Q: How long does surface preparation typically take?

A: The time required for surface preparation depends on the condition of the existing substrate. It can range from a few hours to several days, depending on the extent of grinding or shot blasting needed.

2. Mixing and Application:

Once the surface is prepared, it’s time to mix the epoxy resin with decorative aggregates to create the terrazzo mixture. The ratio of resin to aggregate varies depending on the desired look and thickness of the flooring system. Careful measurement and thorough mixing are crucial to achieve a consistent color and texture throughout the installation.

After mixing, the terrazzo mixture is poured onto the prepared substrate and spread evenly using trowels or rollers. During this process, skilled installers work meticulously to ensure an even distribution of aggregates and eliminate any air bubbles within the resin.

FAQs:

Q: What types of decorative aggregates can be used in epoxy terrazzo flooring?

A: Epoxy terrazzo allows for a wide range of decorative aggregates, including marble chips, glass chips, mother of pearl, or even recycled materials like crushed porcelain. The choice of aggregates depends on the desired aesthetic and design.

Q: Can epoxy terrazzo be installed on vertical surfaces?

A: Yes, epoxy terrazzo can be applied to vertical surfaces such as walls or stairs. However, the mixture may need to be adjusted slightly to ensure proper adhesion and prevent sagging.

3. Grinding and Polishing:

Once the terrazzo mixture has cured, it is time to grind and polish the surface to reveal its full beauty. This process involves using a series of progressively finer diamond abrasive pads to remove any imperfections and achieve a smooth, glossy finish.

The grinding process starts with coarse-grit pads to level the surface and remove any excess resin. As the process continues, finer-grit pads are used to refine the surface further. Finally, a polishing compound is applied to enhance the shine and protect the epoxy terrazzo flooring from wear and tear.

FAQs:

Q: How long does the grinding and polishing process take?

A: The duration of grinding and polishing depends on various factors such as the size of the area, desired level of sheen, and condition of the terrazzo surface. It can range from a few hours for smaller projects to several days for larger areas.

Q: Is it possible to achieve different levels of sheen with epoxy terrazzo flooring? A: Yes, it is possible to achieve different levels of sheen with epoxy terrazzo flooring. The level of sheen can be adjusted by using different polishing pads and compounds during the grinding and polishing process. This allows for customization to match the desired aesthetic and design of the space. Q: How durable is epoxy terrazzo flooring?

A: Epoxy terrazzo flooring is highly durable and long-lasting. It is resistant to stains, scratches, and abrasions, making it suitable for high-traffic areas. Additionally, it is easy to clean and maintain, further enhancing its durability. Overall, careful measurement and thorough mixing are important for achieving a consistent color and texture in epoxy terrazzo flooring. Skilled installers should ensure an even distribution of aggregates and eliminate air bubbles during the pouring and spreading process. Epoxy terrazzo can be installed on vertical surfaces, but adjustments may be needed to ensure proper adhesion. After curing, the surface is ground and polished using diamond abrasive pads to achieve a smooth, glossy finish. The duration of this process depends on various factors and different levels of sheen can be achieved through customization. Epoxy terrazzo flooring is highly durable, resistant to stains and scratches, and easy to clean and maintain.