With concrete flooring, as soon as the floors are actually laid, they're polished to a high gloss as well as left on display. Those the majority of enthusiastic about building eco alternative houses have been among the first person to adopt polished concrete floors, and also with good reason. Warehouses and basements are actually the best applications for polished concrete floor.

Images about Hambro Concrete Floor System

This particular kind of program works to stop long lasting degeneration of done concrete floors. Regardless of what could leak on it or even be dragged across it, concrete flooring is almost indestructible. When you are thinking that you would like to have a lot more choices than simply a glossy surface as well as color to work into your design goals, subsequently polished concrete is now the technique to go.

Hambro D500 Structural Floor System, Hambro Joist Swirnow Structures

Polished concrete floors are now being seen when the number one information that is both highly functional and decorative for public structures. You are able to blend it in other surfaces to compliment your flooring option. Buyers usually have many preferences. The notion of a lifeless grey concrete floor has been replaced with exquisite surfaces that could look like granite, marble, and also tile.

HAMBRO D500 Composite Floor System

Hambro D500 u2013 MAB Construction Systems, LLC

Hambro D500 Composite Floor – Hambro by Canam

Hambro Structural Building Systems – Canam-Buildings

Hambro Composite Floor System u2013 ICF Homestead « ICF Homestead

Hambro D500 composite floor system

Hambro D500 Structural Floor System, Hambro Joist Swirnow Structures

Hambro Structural Building Systems – Canam-Buildings

Hambro D500 u2013 MAB Construction Systems, LLC

Hambro Composite Floor System – Canam-Buildings Membrane roof

HAMBRO D500 Composite Floor System

Design u2013 MAB Construction Systems, LLC

Related Posts:

- Exterior Concrete Floor Tiles

- How To Stain Concrete Floors DIY

- Concrete Floor Paint Primer

- Indoor Concrete Floor Stain

- Concrete Floor On Second Story

- How To Install Toilet Flange On Concrete Floor

- Tiling A Concrete Floor Leveling

- Laying Ceramic Tile Over Concrete Floor

- How To Install Tile Over Concrete Floor

- No Slip Concrete Floor Paint

The Hambro Concrete Floor System: A Revolution in Construction

Introduction:

In the world of construction, innovation is key to staying ahead of the competition. One such innovation that has revolutionized the way buildings are constructed is the Hambro Concrete Floor System. This unique system combines the strength and durability of concrete with the flexibility and speed of installation, resulting in a superior flooring solution for a wide range of projects. In this article, we will explore the various aspects of the Hambro Concrete Floor System, from its components and installation process to its advantages and frequently asked questions.

1. Components of the Hambro Concrete Floor System:

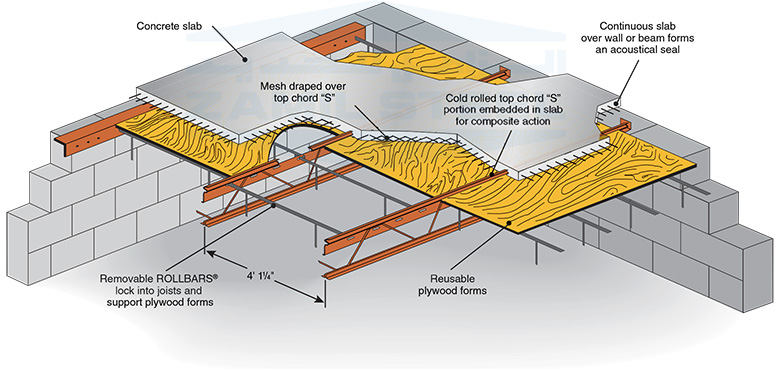

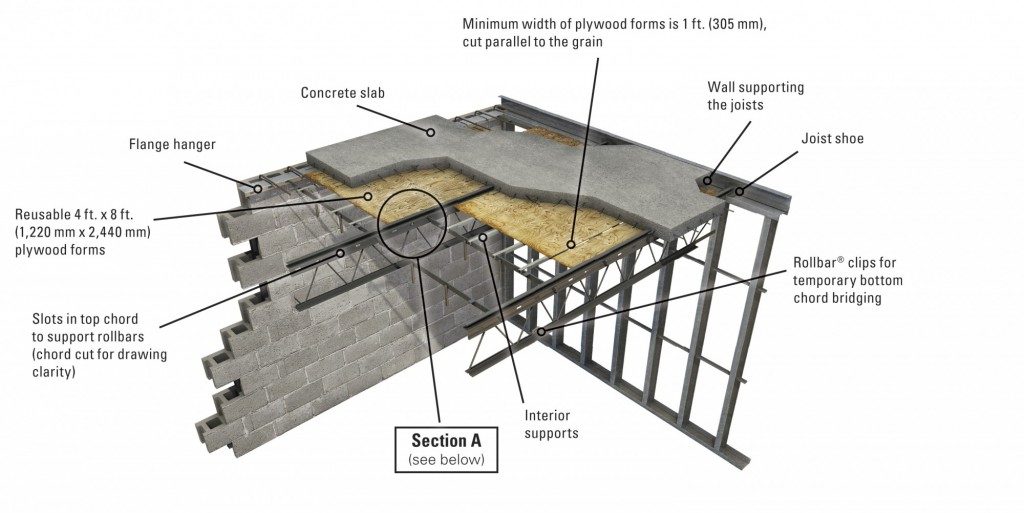

The Hambro Concrete Floor System consists of three primary components: steel joists, concrete, and composite deck. The steel joists serve as the main structural support for the floor, providing strength and stability. These joists are specifically designed to accommodate various loads and span lengths, making them suitable for both residential and commercial applications.

The concrete component is poured onto the composite deck, which acts as a formwork during installation. The composite deck is made from galvanized steel sheets that are embossed with ribs to enhance bonding with the concrete. This combination creates a robust and durable floor that can withstand heavy loads and provide excellent fire resistance.

2. Installation Process:

The installation process of the Hambro Concrete Floor System is highly efficient and time-saving compared to traditional methods. Here’s a step-by-step breakdown of how it works:

Step 1: Structural Design – The first step in installing a Hambro floor system is to design the structure based on specific project requirements. This involves calculating load capacities, span lengths, and other factors that influence joist size and spacing.

Step 2: Joist Placement – Once the structural design is finalized, steel joists are placed according to predetermined spacing guidelines. These joists are typically installed perpendicular to supporting walls or beams using specialized connectors.

Step 3: Composite Deck Installation – After the steel joists are in place, the composite deck is installed over the entire floor area. The sheets are laid horizontally and fastened to the steel joists using self-tapping screws. This process creates a sturdy platform for pouring the concrete.

Step 4: Concrete Pouring – Once the composite deck is securely in place, concrete is poured onto it. The concrete can be pre-mixed or poured on-site, depending on project preferences. During pouring, care must be taken to ensure that the concrete evenly covers the entire floor area and reaches the desired thickness.

Step 5: Curing and Finishing – After the concrete has been poured, it undergoes a curing process to strengthen and harden. This typically involves covering the floor with a curing compound or using wet curing methods. Once the concrete has cured, it can be finished with various surface treatments such as polishing or staining to achieve the desired aesthetic.

3. Advantages of the Hambro Concrete Floor System:

The Hambro Concrete Floor System offers numerous advantages over traditional flooring methods. Let’s explore some of its key benefits:

a) Strength and Durability: The combination of steel joists and concrete creates a floor that is incredibly strong and durable. It can withstand heavy loads and is resistant to fire, making it ideal for both residential and commercial applications.

b) Speed of Installation: Compared to traditional methods that require multiple steps and materials, the Hambro system offers a faster installation process. The use of pre-engineered components and simplified Installation steps allows for quicker construction timelines, saving both time and money.

c) Design Flexibility: The Hambro system offers design flexibility, allowing for customized floor layouts and spans. This makes it suitable for a variety of architectural designs and project requirements.

d) Enhanced Bonding: The embossed ribs on the steel sheets enhance bonding with the concrete, creating a stronger connection between the two materials. This improves overall floor stability and performance.

e) Fire Resistance: The Hambro system provides excellent fire resistance due to the combination of steel and concrete. This enhances safety in both residential and commercial buildings.

f) Sustainability: The Hambro system is environmentally friendly, as it uses recycled steel and reduces the amount of concrete needed compared to traditional methods. This helps to minimize the project’s carbon footprint.

g) Cost-Effective: The Hambro system can be cost-effective compared to traditional flooring methods. Its efficient installation process reduces labor and material costs, making it an economical choice for many construction projects.

Overall, the Hambro Concrete Floor System offers a strong, durable, and efficient flooring solution that meets various project requirements while providing numerous advantages over traditional methods.