With many selections of hardwood floors offered, customers are usually confused about the structure of wood floors leading to buying a floor which does not fit into an allotted financial budget or installation not created for the intended use. Many offshore manufactured products will say they've lightweight aluminum oxide in them but in fact do not.

Images about Hardwood Floor Installation Nailer

Laying down, sanding and sealing a hardwood floor usually takes couple of days. The best part is that maintaining your floors clean is a simple matter of sweeping them a few of times a day using a swifter mop (use a micro roughage pad) and a product as Orange Glo. Plan to generate 3 passes together with your sanding equipment, using increasingly finer sandpaper each time.

Freeman PF18GLCN Pneumatic 18-Gauge 1-3/4″ L-Cleat Flooring Nailer for Bamboo and Exotic Flooring Ergonomic and Lightweight Nail Gun with No Mar Foot

What exactly are the styles of the furniture and walls? You would not wish to buy hardwood floors with a color that does not match those of your furniture and wall space. Engineered hardwood flooring tends to be much slimmer than solid hardwood flooring and it's often glued to the subsurface though it can also be nailed or even stapled.

Installing Solid Hardwood Floors – Fastening By Nails Or Staples

DEWALT Pneumatic 15.5-Gauge Hardwood Flooring Stapler DWMIIIFS

Engineered Hardwood Floors Installation – Hardwood Floor

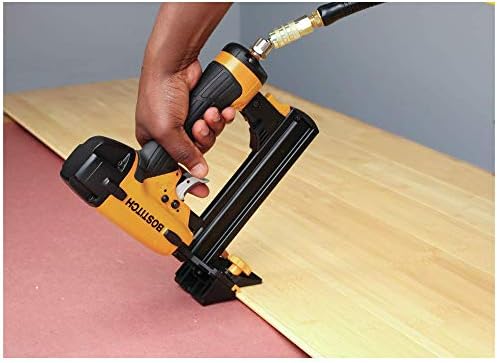

Bostitch Flooring Stapler for Engineered Hardwood (EHF1838K) , Black

Hardwood Flooring Cleat Nailer – MIIIFN BOSTITCH

Nail Gun Depot FAQ Frequently Asked Questions

Home Page – Top Quality

Bostitch Flooring Stapler for Engineered Hardwood (EHF1838K

Freeman Pneumatic 18-Gauge 1-3/4 in. L-Cleat Flooring Nailer PF18GLCN

Bostitch MFN-201 Manual Hardwood Flooring Cleat Nailer, 1-1/2″ to 2″

Dewalt 2 and 1 flooring nailer

BOSTITCH Flooring Nailer, Pneumatic, 1-1/2- to 2-Inch (MIIIFN

Related Posts:

- North American Hardwood Flooring Company Profile

- Nature Hardwood Flooring Reviews

- Bamboo Vs Oak Hardwood Flooring

- Brazilian Walnut Hardwood Flooring Reviews

- Peruvian Walnut Hardwood Flooring

- Finished In Place Hardwood Flooring

- Bruce Hardwood Floor Liquid Wax

- Hickory Hardwood Floor Images

- Hardwood Floor Memorial Day Sale

- Engineered Hardwood Flooring Floating Installation

Title: The Ultimate Guide to Hardwood Floor Installation Nailers

Introduction:

Installing hardwood floors is a significant investment that can enhance the beauty and value of any home. One crucial tool that ensures a successful installation is a hardwood floor installation nailer. This article will delve into the world of hardwood floor installation nailers, providing you with detailed information on their types, features, benefits, FAQs, and tips for choosing the right one for your project.

I. Understanding Hardwood Floor Installation Nailers

A. What is a hardwood floor installation nailer?

A hardwood floor installation nailer is a specialized tool designed to drive nails or staples into hardwood flooring materials with precision and ease, ensuring a secure and professional finish.

B. Types of hardwood floor installation nailers

1. Pneumatic nailers: These nailers use compressed air to drive fasteners into the wood.

2. Manual nailers: These nailers require physical force to drive nails or staples into the flooring material.

II. Benefits of Using a Hardwood Floor Installation Nailer

A. Time-saving efficiency

A quality nailer can significantly speed up the installation process compared to traditional methods like hand nailing or stapling.

B. Enhanced precision and stability

By using a nailer specifically designed for hardwood flooring, you can ensure that each fastener is driven at the perfect angle and depth, resulting in a secure and stable floor.

C. Reduced fatigue and physical strain

Investing in a high-quality nailer reduces the need for manual force, thereby minimizing fatigue and strain on your body during the installation process.

III. Factors to Consider when Choosing a Hardwood Floor Installation Nailer

A. Power source: Pneumatic vs Manual

1. Pneumatic: Offers greater power and efficiency but requires an air compressor.

2. Manual: Suitable for smaller projects or areas where electricity or compressed air is not available.

B. Nail size compatibility

Ensure that the nailer you choose can accommodate the specific nail or staple sizes recommended for your hardwood flooring.

C. Weight and ergonomics

Opt for a nailer that feels comfortable in your hand and is lightweight enough to prevent fatigue during long installation sessions.

D. Adjustable depth settings

Look for a nailer with adjustable depth settings to ensure proper countersinking of nails or staples into the wood.

IV. Frequently Asked Questions about Hardwood Floor Installation Nailers

Q1: Can I use any nailer for hardwood floor installation?

A: It is crucial to use a nailer specifically designed for hardwood floor installation. Regular framing or finish nailers may not have the necessary features, such as the ability to adjust depth or drive nails at the correct angle required for hardwood flooring.

Q2: Do I need an air compressor for a pneumatic nailer?

A: Yes, pneumatic nailers require an air compressor to function correctly. The compressor provides the necessary air pressure to drive nails into the hardwood flooring.

Q3: Can I use staples instead of nails for hardwood floor installation?

A: Yes, many hardwood floor installation nailers are compatible with both nails and staples. However, it is essential to check the manufacturer’s specifications to ensure compatibility and follow any guidelines provided.

V. Tips for Proper Usage and Maintenance of a Hardwood Floor Installation Nailer

A. Read the user manual thoroughly before operating the nailer.

B. Wear appropriate safety gear, including safety glasses and ear protection , to protect yourself from flying debris and loud noises.

C. Keep the nailer clean and free of dust and debris to ensure optimal performance.

D. Regularly check and lubricate the moving parts of the nailer to prevent jamming or malfunctioning.

E. Store the nailer in a dry and secure place when not in use to avoid damage or theft.

F. Follow the manufacturer’s guidelines for regular maintenance and servicing to prolong the lifespan of the nailer.

G. If you encounter any issues or problems with the nailer, contact the manufacturer or a professional for assistance rather than attempting to fix it yourself.

By following these tips and considering the factors mentioned earlier, you can choose the right hardwood floor installation nailer and ensure a smooth and efficient installation process. The size compatibility of the nailer is important to ensure that it can accommodate the specific nail or staple sizes recommended for your hardwood flooring. This will ensure that the nails or staples are properly secured in the wood.

Weight and ergonomics are also important factors to consider. Choosing a nailer that feels comfortable in your hand and is lightweight will help prevent fatigue during long installation sessions. This will make the process more comfortable and efficient.

Adjustable depth settings are essential for proper countersinking of nails or staples into the wood. This allows you to control the depth at which the nails or staples are driven into the hardwood flooring, ensuring a professional and finished look.

When it comes to choosing a nailer for hardwood floor installation, it is crucial to use one specifically designed for this purpose. Regular framing or finish nailers may not have the necessary features, such as adjustable depth settings or the ability to drive nails at the correct angle required for hardwood flooring.

Pneumatic nailers require an air compressor to function correctly. The compressor provides the necessary air pressure to drive nails into the hardwood flooring. So, if you choose a pneumatic nailer, make sure you have access to an air compressor.

Many hardwood floor installation nailers are compatible with both nails and staples. However, it is important to check the manufacturer’s specifications to ensure compatibility and follow any guidelines provided.

To properly use and maintain a hardwood floor installation nailer, it is important to read and understand the user manual thoroughly before operating it. Wear appropriate safety gear, such as safety glasses and ear protection, to protect yourself from flying debris and loud noises.

Keeping the nailer clean and free of dust and debris will ensure optimal performance. Regularly checking and lubricating the moving parts of the nailer will help prevent jamming or malfunctioning.

When not in use, store the nailer in a dry and secure place to avoid damage or theft. Following the manufacturer’s guidelines for regular maintenance and servicing will help prolong the lifespan of the nailer.

If you encounter any issues or problems with the nailer, it is best to contact the manufacturer or a professional for assistance rather than attempting to fix it yourself. This will ensure that any problems are addressed correctly and safely.

By considering these factors and following these tips, you can choose the right hardwood floor installation nailer and ensure a smooth and efficient installation process.