With the many layers of engineered hardwood pressed and glued together in reverse directions, under extreme pressures, the dimensional balance of engineered wood floors is actually an excellent product for installation on un even floors, transferring a dull and inefficient space into a space with character and charm. And for the sake of yours, I really hope you followed the steps carefully & picking out premium quality flooring.

Images about Hardwood Floor Installation Subfloor

Seek out professional skilled advice when choosing a hardwood floor wax and cleaner designed to protect as well as beautify the specific hardwood material put in before application of any such material. To sweep the floor one or more times a week is actually the best thing that could be done only of course when there are actually especial occasions that call for appropriate cleaning.

Flooring Over Plank Subfloor – Fine Homebuilding

We are able to also make use of absorbent rugs especially in areas where frequent water or perhaps liquid spills is usually unavoidable. In case, finishing is actually great and there won't be any dents and scratches, mop it with water which will add a brand new gloss to it. Unfinished hardwood flooring is sanded, tarnished, and coated onsite following set up. The thinner nature of engineered flooring reduces or perhaps eliminates the choice of refinishing the floors when they use over time.

How to Level a Subfloor for a Hardwood Floor Install

What is a Subfloor? The Foundation Beneath the Beauty Empire

Your Sub-Floor and You: What Lies Beneath – Reno-Tahoe-Nevada

floor – Proper subfloor for hardwood in a renovation – Home

9 Common Sub-Floor Installation Mistakesu2014and How to Avoid Them

Floating Wood Floor: Install One in 8 Steps – This Old House

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/19493650/0405_flooring_illo.jpg)

A Guide to Subfloors Used Under Wood Flooring Wood Floor Business

Types of Subfloor Materials in Construction Projects

/GettyImages-892047030-5af5f46fc064710036eebd22.jpg)

How To Install Hardwood Flooring

How to Acclimate Plank Floors Before Installing

Hardwood Floor Underlayment: Is Underlayment Necessary for

Installing Wood Subfloors Over Concrete Hardwood Floors Magazine

Related Posts:

- Hardwood Floor Tile Entryway

- Royal Image Hardwood Flooring Reviews

- Hardwood Flooring Toronto Cost

- Hardest Most Durable Hardwood Flooring

- Natural Walnut Engineered Hardwood Flooring

- Exotic Walnut Engineered Hardwood Flooring

- Best Value Engineered Hardwood Flooring

- Hardwood Flooring Companies Hiring

- Carpet And Hardwood Floor Cleaning Machine

- Link Hardwood Flooring Reviews

Installing a Hardwood Floor Subfloor

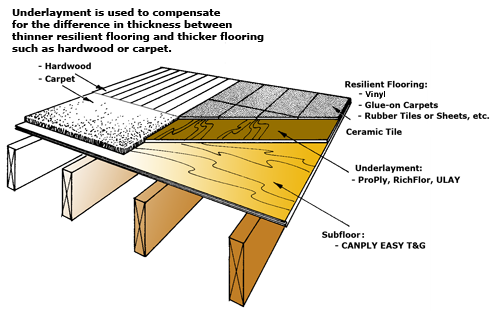

Installing a hardwood floor subfloor is an important part of ensuring that your hardwood floors look and perform their best. A subfloor provides a stable and level surface for the hardwood floor to lay on, making it easier to install and helping to prevent any potential issues with the flooring in the future. With proper preparation and planning, you can have your new hardwood floors installed in no time.

Why Install a Subfloor?

Installing a subfloor before laying down your hardwood flooring is essential for two main reasons. First, it helps protect the wood flooring from potential problems that can be caused when laying directly on an uneven or unstable surface. Second, a subfloor helps provide additional insulation and soundproofing, which can help keep energy costs down.

Types of Subfloor Materials

When it comes to choosing the right subfloor material, there are a few factors to consider. The most common materials used for hardwood floor subfloors are plywood, OSB (oriented strand board), and particleboard. Plywood is generally the preferred choice since it provides the most stability and has the least amount of movement over time. OSB is also an option, but it tends to be more prone to warping and should only be used in dry areas where moisture isn’t a concern. Particleboard should be avoided as it is not as stable nor does it provide as much insulation or soundproofing.

Subfloor Preparation

Once you’ve chosen the right type of subfloor material for your project, you’ll need to prepare the surface for installation. This includes removing any existing flooring and cleaning up any debris or dirt that may have accumulated over time. You’ll also want to check for any noticeable signs of damage or wear such as holes or cracks in the surface that might need to be repaired before proceeding with installation.

Subfloor Installation

Once you’ve prepared the surface, you can begin installing the subfloor panels. Start by measuring out where each panel needs to go and use a level to make sure everything is even before securing them into place. It’s important that each panel is securely fastened so that there are no gaps between them which could cause potential problems with the hardwood flooring installation later on down the road. Once all of the panels are securely fastened into place you can start laying down your hardwood flooring.

FAQs About Hardwood Floor Subfloors

Q: What types of materials should I use for my hardwood floor subfloor?

A: The most common materials used for hardwood floor subfloors are plywood, OSB (oriented strand board), and particleboard. Plywood is generally recommended since it provides the most stability with minimal movement over time while OSB should only be used in dry areas where moisture isn’t a concern. Particleboard should be avoided altogether since it doesn’t provide enough stability or insulation/soundproofing capabilities compared to other options available.

Q: How do I prepare my subfloor before installation?

A: Before beginning installation of your hardwood floor subfloors, It’s important to properly prepare the surface. This includes removing any existing flooring and cleaning up any debris or dirt that may have accumulated over time. You’ll also want to check for any noticeable signs of damage or wear such as holes or cracks in the surface that might need to be repaired before proceeding with installation. Once you’ve done this, you can begin laying down your subfloor panels.