Garage flooring coatings have created advancement of engineering and in new and different levels of coatings. Each flooring has good and bad characteristics, for this reason you need to complete a bit of house effort to pick the best one for you. Repeated connection with corrosive agents, such as petroleum, antifreeze, and rock salt is able to lead to permanent cracks as well as other significant hurt to concrete floors.

Images about Plywood Garage Floor

You will find a variety of varieties of plastic tiles as well as the quality of the tiles will change greatly. You can get a fundamental, cheap garage flooring treatment or perhaps a high end garage flooring treatment. Chances are they would adhere to the rubber storage area flooring and operating the automobile out would be a hazard. Let’s go over a couple of misconceptions that surround garage floor protectors.

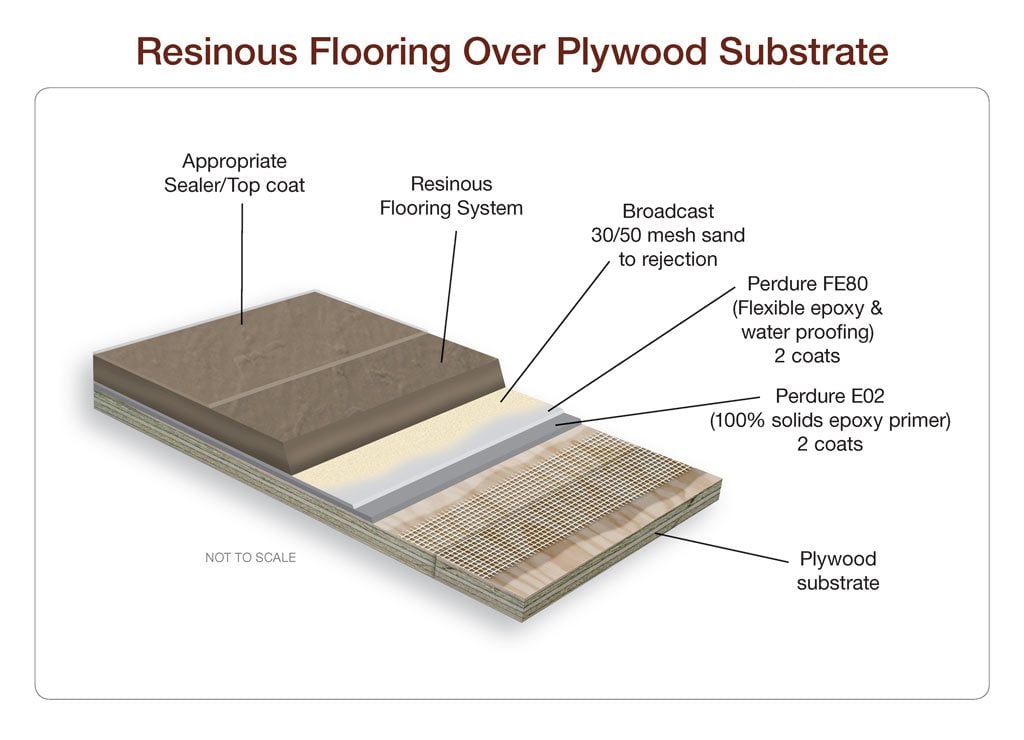

Preparing Plywood Substrates for the Application of Resinous

If you are not confident determining just how much you need, ask for assistance. What would you want to reach with the new garage floor of yours covering? Have you been thinking about security? The design is patterned after the checkered flag. They generally have some sort of an attaching device which allows for them to click together and keep in place.

Specs for prebuilt garages Pennsylvania Maryland and West Virginia

My WOODEN FLOOR Saga: How I rebuilt the floor in my work shop to

Burnt Plywood Burnt plywood floor, Cheap home decor, Home

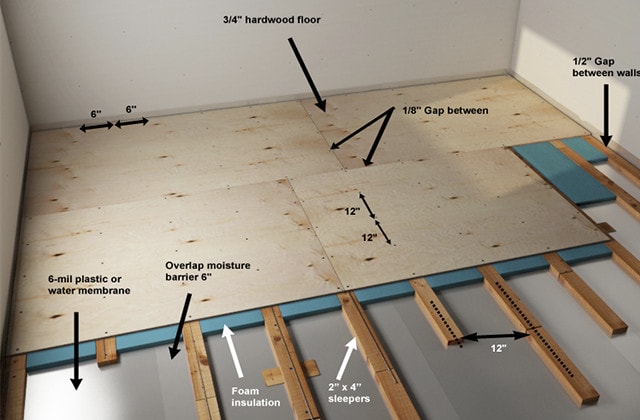

How-to install a wood subfloor over concrete RONA

HyperFLEX Epoxy Flexible Membrane Concrete Wood Low Temp 40°F 100% Solids

BLT Ribbed Garage Floor Lining

Installing Wood Flooring Over Concrete (DIY)

How to Apply Epoxy Coating to a Garage Floor – This Old House

/cdn.vox-cdn.com/uploads/chorus_asset/file/19496068/h0308stepbystep07_1.jpg)

The North American Leader of High Quality Garage Interiors!

3 of 52: Garage Floor All My Lifeu0027s A Circle

Epoxy Garage Floor Coating in Oak Island , NC Garage Experts of

Place plywood sheet Floor insulation, Diy flooring, Garage floor

Related Posts:

- Light Grey Garage Floor Paint

- Metallic Epoxy Garage Floor Kit

- Quikrete Tan Epoxy Garage Floor Coating

- Black And White Garage Floor Epoxy

- Garage Floor Weather Mats

- How To Paint Garage Floor Behr

- Epoxy Seal Garage Floor Paint Reviews

- Garage Door Floor Seal Kit

- Sherwin Williams Garage Floor Epoxy Reviews

- How To Protect Garage Floor

Title: Plywood Garage Floor: A Versatile and Durable Flooring Solution

Introduction:

When it comes to designing and renovating a garage, choosing the right flooring is of utmost importance. A plywood garage floor is an excellent option that offers versatility, durability, and affordability. This article explores the benefits of using plywood as a garage floor material, its installation process, maintenance requirements, and answers some frequently asked questions related to this topic.

I. Why Choose Plywood for Your Garage Floor?

1.1 Affordability:

Plywood is a cost-effective choice for garage flooring. Compared to other materials like epoxy or concrete, plywood is relatively inexpensive, making it an attractive option for homeowners on a budget.

1.2 Durability:

Contrary to common misconceptions, plywood is a highly durable material that can withstand heavy loads without warping or cracking. It provides a sturdy foundation for parking vehicles, storing equipment, or setting up a workshop in your garage.

1.3 Versatility:

Plywood comes in various thicknesses and grades, allowing you to select the most suitable one for your specific needs. It can be used as a standalone flooring solution or as an underlayment for other types of flooring such as tiles or vinyl.

II. Installation Process of Plywood Garage Floors:

2.1 Preparing the Subfloor:

Before installing plywood as your garage floor, ensure that the subfloor is clean, dry, and level. Remove any existing flooring or debris and repair any cracks or unevenness in the concrete surface.

2.2 Measuring and Cutting the Plywood:

Measure the dimensions of your garage accurately and cut the plywood sheets accordingly using a saw or circular saw. Leave a small gap around the perimeter of the floor to allow for expansion.

2.3 Securing the Plywood Sheets:

Lay down the first sheet of plywood along one edge of the garage floor and fasten it securely using screws or nails. Continue this process, ensuring that each sheet is tightly secured to the subfloor and adjacent sheets.

2.4 Sealing the Plywood:

To enhance the longevity of your plywood garage floor, apply a sealant or polyurethane coating to protect against moisture, stains, and wear. This step will also provide a smooth and polished finish to the floor surface.

III. Maintenance and Care:

3.1 Regular Cleaning:

Maintaining a clean garage floor is essential for its longevity and appearance. Sweep away dirt, debris, and dust regularly to prevent scratches or damage to the plywood surface. Additionally, mop with a mild detergent solution to remove any stubborn stains or spills.

3.2 Protecting Against Moisture:

Plywood is susceptible to water damage if not properly protected. Ensure that your garage has adequate insulation and ventilation to prevent moisture buildup. In case of accidental spills or leaks, promptly dry them up to avoid long-term damage.

3.3 Resealing when Necessary:

Over time, the protective sealant on your plywood garage floor may begin to wear off. Keep an eye out for signs of discoloration or reduced resistance to stains. If required, reapply a fresh coat of sealant to maintain its durability and aesthetic appeal.

IV. Frequently Asked Questions (FAQs):

Q1: Can plywood withstand heavy vehicle traffic without getting damaged?

A1: Yes, plywood is designed to handle heavy loads without warping or cracking. However, it is crucial to select a higher grade plywood with sufficient thickness for optimal strength and durability. Q2: Can plywood be used in a garage with high humidity or moisture levels?

A2: While plywood is generally resistant to moisture, it is important to take precautions in high humidity or moisture-prone areas. Proper insulation and ventilation should be in place to prevent moisture buildup. Additionally, applying a sealant or polyurethane coating can provide an extra layer of protection against moisture damage.

Q3: How long does the sealant on a plywood garage floor last?

A3: The longevity of the sealant depends on various factors such as the quality of the sealant used, the amount of traffic on the floor, and the level of maintenance and care. On average, a good quality sealant can last anywhere from 2-5 years before needing reapplication.

Q4: Can I install tiles or vinyl over plywood garage flooring?

A4: Yes, plywood can serve as a suitable underlayment for other types of flooring such as tiles or vinyl. Ensure that the plywood surface is clean, level, and securely fastened before installing the desired flooring material.

Q5: How do I repair damaged plywood in my garage floor?

A5: If you notice any damaged or warped plywood in your garage floor, it is best to replace those specific sheets with new ones. Remove the damaged section carefully and cut a replacement piece to fit. Securely fasten the new plywood sheet to the subfloor and ensure that it is level with the surrounding area.

Overall, plywood can be a durable and cost-effective option for your garage flooring needs. By following proper installation techniques and regular maintenance, you can enjoy a functional and attractive garage floor for years to come.