There are various places where the concrete polishing is actually being used and a lot of people tend to prefer the polished concrete floor because of all of the benefits that accrue to the owners of such floors. For that reason it will come as no surprise whenever you walk into a dwelling that has concrete floor polishing which there are no cracks, leaks or damages on the outside.

Images about Precast Concrete Floor Construction

You will find a few ways to approach cleaning concrete floor, depending on the appearance of its, whether it centrally located inside or outside, whether or not the concrete have been sealed and the current state of its of cleanliness. Polished concrete floors these days has been essentially the most popular choices in every house and business constructions.

Hollowcore Residential Applications

Each time you will undertake maintenance work for the polished concrete floors of yours, you want spending simply a portion of capital as compared to other flooring available options. In domestic situations polished concrete floors are selected for the good looks of its, but in industrial situations it's recommended because of practicality; these floors are also very functional.

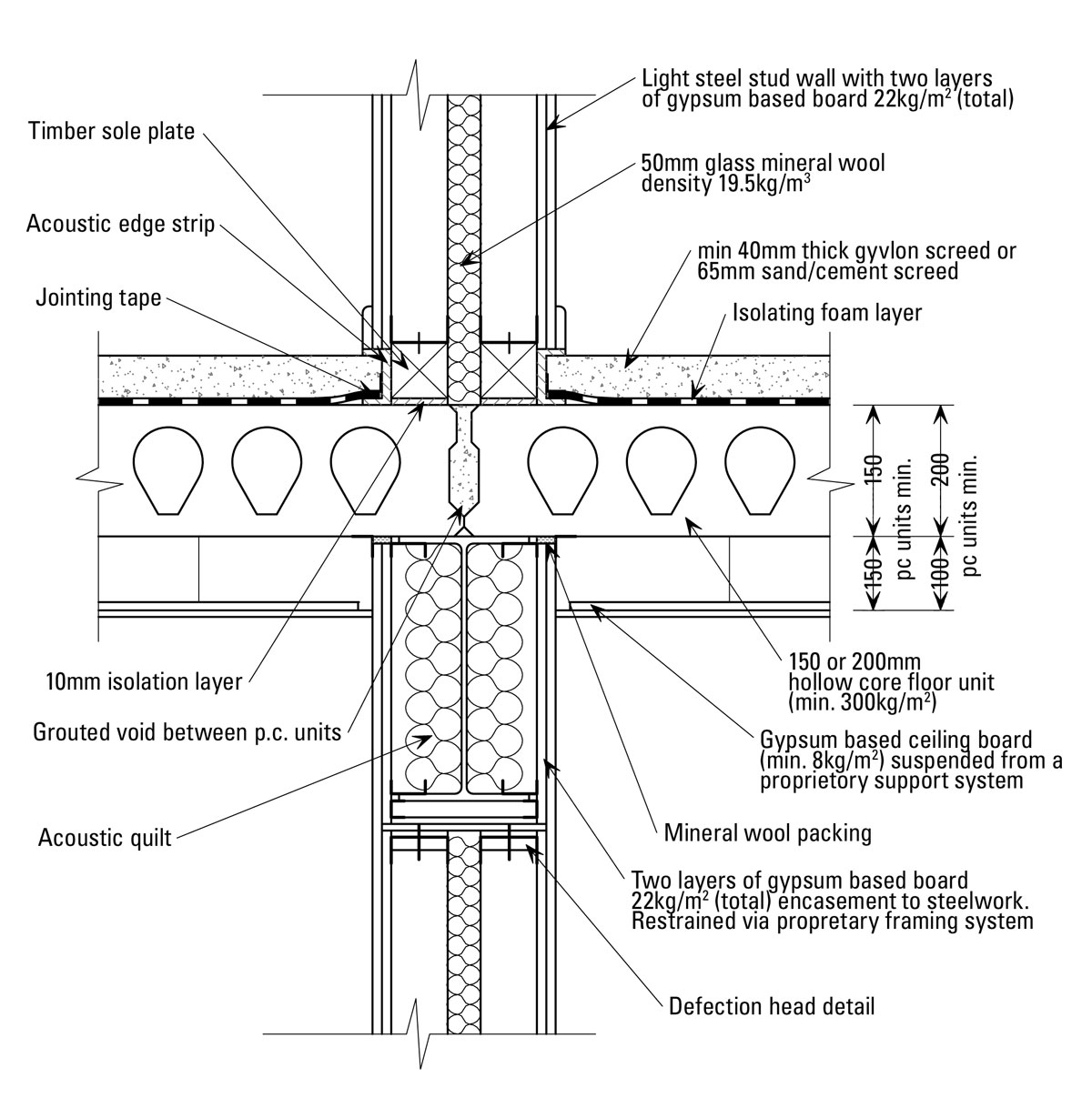

Reinforced concrete precast core floor slab – Thomas Armstrong

Hollow-core slab – Wikipedia

Toppings and Screeds for Precast Concrete Floors – Fibre Concrete

Lighter, Stronger Precast Concrete Floor System – NPCA

Opportunities for precast prestressed concrete floor slabs in

T-SLAB takes precast concrete floor systems to the next level

AD 313: Precast concrete floors in steel framed buildings

PreCast Construction Precast concrete, Precast concrete slabs

Hollowcore Flooring – Precast Concrete from Mannok

Precast Concrete Beams and Slabs Engineering For Change

Hassle-free insulated precast concrete flooring

STRUCTURE magazine Creating an Opening in Existing Floors

Related Posts:

- Concrete Floor Grinding Pads

- Clear Epoxy Coating For Concrete Floors

- Removing Tile Glue From Concrete Floor

- How To Install Tile Over Concrete Floor

- Concrete Floor Paint Patterns

- Reinforced Concrete Floor Systems

- Advantages Of Precast Concrete Floors

- How To Pour Concrete Floor In Bathroom

- Concrete Floor Finishes Photos

- Concrete Floor Faux Finish

Introduction to Precast Concrete Floor Construction

Precast concrete floor construction is a method of constructing floors which involves the use of precast concrete slabs or panels. Precast concrete floors are typically used in commercial and industrial applications, as they offer superior strength and durability compared to other types of flooring materials like wood or tile. Precast concrete floors can also be cost-effective, as they require less labor and materials than other forms of construction. Precast concrete floors are also resistant to fire and water damage, making them ideal for industrial and commercial applications.

Advantages of Precast Concrete Floor Construction

The main advantage of precast concrete floor construction is its strength and durability. Precast concrete is much stronger than other materials like wood or tile, and it can withstand heavy loads and impacts without breaking or cracking. It is also resistant to fire, water damage, and mold growth, making it ideal for industrial and commercial applications. Additionally, precast concrete floors are relatively easy to install, as they can be quickly assembled onsite without the need for complicated installation processes. This makes precast concrete an attractive choice for both commercial and residential projects.

Process of Installing Precast Concrete Floors

The process of installing precast concrete floors is relatively straightforward. First, the foundation must be prepared by leveling the surface and filling any gaps with mortar or grout. After this has been completed, the pre-fabricated panels are placed on top of the foundation. The panels are then secured with anchors that provide additional stability against shifting or movement. Once this is done, the joints between the panels are filled with mortar or grout to ensure a secure seal. Finally, any exposed edges or corners are sealed with an additional layer of mortar or grout to provide additional protection against moisture infiltration.

Costs Associated with Precast Concrete Floor Construction

The cost associated with pre-casting concrete floors will vary depending on a number of factors such as the size of the project and the type of materials used. Generally speaking, pre-casting concrete floors will cost more than other types of flooring materials like wood or tile due to the complexity of the installation process. However, in most cases, pre-casting will still be more cost effective than other forms of construction due to its superior strength and durability.

FAQs about Precast Concrete Floor Construction

Q: What are the benefits of using precast concrete floor construction?

A: The main benefit of using precast concrete floor construction is its strength and durability compared to other materials such as wood or tile. Additionally, precast concrete is resistant to fire, water damage, and mold growth which makes it an ideal choice for both residential and commercial projects.

Q: How much does it cost to install a precast concrete floor?

A: The cost associated with installing a pre-casting concrete floor will vary depending on a number of factors such as size and material type used. Generally speaking, pre-casting concrete floors will be more expensive than other types of flooring materials but may offer greater value due to its superior strength and durability when compared to alternatives such as wood or tile.

Q: Is precast concrete difficult to install?

A: No, precast concrete is not difficult to Install. It can be quickly assembled onsite without the need for complicated installation processes. This makes precast concrete an attractive choice for both commercial and residential projects as it is relatively easy to install.

What are the advantages of precast concrete floor construction?

1. Speed: Precast concrete floor construction can be completed quickly and efficiently. The precast units are manufactured off-site and then installed on-site, which significantly reduces the time needed to construct a building and provides a quicker return on investment.2. Quality and Durability: Precast concrete floors are designed to be long-lasting and are resistant to wear and tear, fire, rot, and pests. They are also highly durable in extreme environments or areas of high traffic.

3. Cost-effectiveness: Precast concrete flooring is cost-effective due to its reduced installation time and lower labor costs compared to traditional cast-in-place concrete floors.

4. Versatility: Precast concrete flooring is versatile enough to be used in both residential and commercial applications. Its strength and durability make it suitable for a variety of uses including basements, warehouses, garages, patios, and more.

5. Sustainability: Precast concrete floor construction is an environmentally friendly choice as it makes use of recycled materials, does not require additional finishing processes (which often involve harsh chemicals), and requires minimal energy for production and transportation.