It is flawless in addition to non-porous, staying away from some type of bacterial growth or mould on it. The benefit of making use of epoxy flooring is that whenever you use epoxy, you could be certain that you’re using a solution that is going to give the flooring of yours greater power as well as resilience. It is quite simple to apply as well as has hardly any maintenance.

Images about Quartz Epoxy Floor Coating

Even if you spill some viscous fluid which is a substance agent, you are going to be in a position to do away with the fluid in a jiffy. Epoxy is made out of a blend of liquid hardening chemicals and liquid polymer resin. It will make your dull as well as sedentary concrete floor look elegant and harm free. Epoxy flooring comes with strong adhesive characteristics that make it long-lasting, dirt and dust resistant as well as inflammable.

Epoxy Quartz Flooring: Right For Your Business

Few are left turned into participating in areas or into game areas with dart boards or even pool tables. Many people work with epoxy to cover the garage floors of theirs, since the material resists solvents, chemicals, lubricants and hot tire marks. For all those structures housing significant machinery succeeds, epoxy floor coating is able to withstand some quantity of sensible influence with no charring.

Decorative Quartz Polymer Sands for Epoxy Floors

Appealing epoxy floors are going to make some field beautiful and will increase the worth of the structure the floors are being installed in. In case you consume a clean looking garage floors then epoxy flooring is actually the answer for you. Most of these qualities deliver longer durability of surfaces. These days, basecoats are obtainable in any color imaginable.

Quartz – Epoxy Flooring Contractor u0026 Supplier

Colored Epoxy Quartz Floor Coating Systems for Concrete

Wear Resistance Colored Quartz Sand Epoxy Floor Paint for Concrete

Quartz Epoxy Flooring Systems 856-455-6777 Floor Skinz

Benefits of Broadcast Quartz Floors

Broadcast vs Troweled Quartz Systems: Which is Right For Your Job

Quartz Epoxy Floor Installation in Metro Detroit Great Lakes Garage

Quartz Sand Epoxy Flooring, Decorative, Stable Quartz Epoxy Flooring

100% Solids Color Quartz Epoxy Floor System – Life Specialty

Quartz System Garage Floor Coating Rasmusen

Decorative Quartz Polymer Sands for Epoxy Floors

Related Posts:

- Garage Floor Epoxy Canada

- Sherwin Williams Epoxy Floor Coating Reviews

- Sika Garage Floor Epoxy

- Professional Epoxy Garage Floor Coating

- Epoxy And Urethane Floor Coatings

- How To Install Epoxy Natural Stone Flooring

- Epoxy Floor Paint Rustoleum

- Metallic Epoxy Kitchen Floor

- 100 Epoxy Floor Coating

- Metallic Epoxy Floor Precio

Quartz Epoxy Floor Coating: Durable and Aesthetically Pleasing

Introduction:

Quartz epoxy floor coating has gained immense popularity in recent years due to its durability, aesthetic appeal, and versatility. This innovative flooring solution combines the strength of epoxy resin with the beauty of quartz aggregates, resulting in a seamless, long-lasting, and visually stunning floor surface. In this article, we will explore the various aspects of quartz epoxy floor coating, including its benefits, application process, maintenance requirements, and frequently asked questions.

I. The Benefits of Quartz Epoxy Floor Coating:

1. Durability: One of the major advantages of quartz epoxy floor coating is its exceptional durability. The combination of epoxy resin and quartz aggregates creates a strong and impact-resistant surface that can withstand heavy foot traffic, machinery, and chemicals. This makes it an ideal choice for industrial facilities, commercial spaces, garages, and even residential applications.

FAQ: Can quartz epoxy floor coating withstand high temperatures?

Answer: Yes, quartz epoxy floor coating is highly resistant to heat and can withstand temperatures up to 180°F (82°C). It is commonly used in areas where there is exposure to hot equipment or processes.

2. Aesthetic Appeal: Quartz epoxy floor coating offers a wide range of design options to suit any space. The quartz aggregates come in various colors and sizes, allowing you to create custom patterns or designs that complement your interior décor. Whether you prefer a sleek and minimalist look or a vibrant and eye-catching design, quartz epoxy floor coating can be customized to meet your aesthetic preferences.

FAQ: Can I customize the color of my quartz epoxy floor coating?

Answer: Absolutely! Quartz epoxy floor coating can be customized to match any color scheme or design concept. You can choose from a vast selection of quartz aggregate colors to create a unique and personalized look for your space.

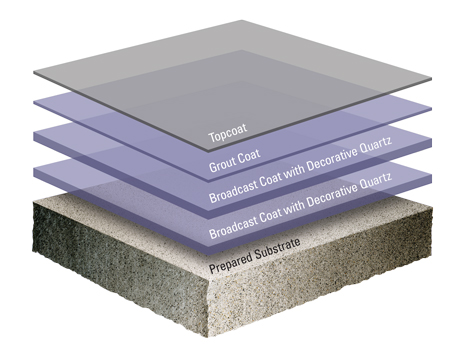

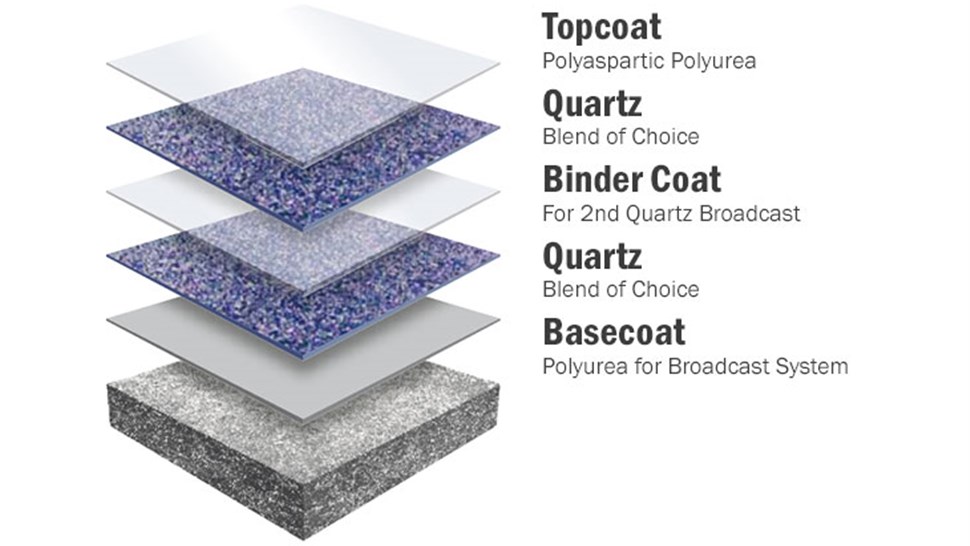

3. Seamless Installation: The installation process of quartz epoxy floor coating involves applying multiple layers of epoxy resin mixed with quartz aggregates. This creates a seamless and level surface that eliminates any joints or seams where dirt, bacteria, or moisture can accumulate. The absence of seams also enhances the overall appearance of the floor, giving it a polished and professional look.

FAQ: How long does it take to install quartz epoxy floor coating?

Answer: The installation time of quartz epoxy floor coating depends on various factors such as the size of the area, surface preparation requirements, and curing time. On average, the installation process can take anywhere from a few days to a week.

II. The Application Process:

1. Surface Preparation: Before applying quartz epoxy floor coating, proper surface preparation is crucial to ensure optimal adhesion and longevity. This typically involves cleaning the floor thoroughly to remove any dirt, oil, or existing coatings. In some cases, mechanical methods like shot blasting or diamond grinding may be required to achieve a clean and porous surface.

2. Primer Application: Once the surface is prepared, a primer coat is applied to promote adhesion between the existing substrate and the quartz epoxy system. The primer helps prevent any potential issues such as delamination or bubbling.

3. Quartz Epoxy Application: After the primer coat has dried, multiple layers of epoxy resin mixed with quartz aggregates are applied to the prepared surface. These layers are usually self-leveling, allowing for easy application and ensuring a smooth finish.

4. Topcoat Protection: To enhance durability and chemical resistance, a clear topcoat is applied over the quartz epoxy system. This topcoat acts as A protective layer, preventing any damage from chemicals, abrasion, or UV exposure. It also adds a glossy finish to the floor, enhancing its overall appearance and making it easier to clean and maintain.

Overall, quartz epoxy floor coating offers numerous benefits such as heat resistance, aesthetic appeal, seamless installation, and durability. It can be customized to match any design concept and is suitable for various industries and spaces. The application process involves proper surface preparation, primer application, quartz epoxy application, and topcoat protection to ensure optimal adhesion and longevity of the floor coating. Quartz epoxy floor coating is a popular choice for many industries and spaces due to its various benefits. Here are some key points about the application process and advantages of quartz epoxy floor coating:

1. Customization: Quartz epoxy floor coating can be customized to match any color scheme or design concept. With a wide selection of quartz aggregate colors to choose from, you can create a unique and personalized look for your space.

2. Seamless Installation: The installation process involves applying multiple layers of epoxy resin mixed with quartz aggregates. This creates a seamless and level surface that eliminates joints or seams where dirt, bacteria, or moisture can accumulate. The absence of seams also enhances the overall appearance of the floor, giving it a polished and professional look.

3. Installation Time: The installation time of quartz epoxy floor coating depends on factors such as the size of the area, surface preparation requirements, and curing time. On average, the installation process can take anywhere from a few days to a week.

The application process of quartz epoxy floor coating involves several steps:

1. Surface Preparation: Proper surface preparation is crucial to ensure optimal adhesion and longevity. This includes cleaning the floor thoroughly to remove any dirt, oil, or existing coatings. In some cases, mechanical methods like shot blasting or diamond grinding may be required to achieve a clean and porous surface.

2. Primer Application: A primer coat is applied to promote adhesion between the existing substrate and the quartz epoxy system. The primer helps prevent issues such as delamination or bubbling.

3. Quartz Epoxy Application: After the primer coat has dried, multiple layers of epoxy resin mixed with quartz aggregates are applied to the prepared surface. These layers are usually self-leveling, allowing for easy application and ensuring a smooth finish.

4. Topcoat Protection: A clear topcoat is applied over the quartz epoxy system to enhance durability and chemical resistance. This topcoat acts as a protective layer against damage from chemicals, abrasion, or UV exposure. It also adds a glossy finish to the floor, enhancing its overall appearance and making it easier to clean and maintain.

Overall, quartz epoxy floor coating offers numerous benefits such as heat resistance, aesthetic appeal, seamless installation, and durability. It can be customized to match any design concept and is suitable for various industries and spaces. The application process involves proper surface preparation, primer application, quartz epoxy application, and topcoat protection to ensure optimal adhesion and longevity of the floor coating.