In case you are redoing a house or even considering building a brand new one after that you need to place garage flooring high on the top priority list. Epoxy flooring color is used to seal porous cement floor surfaces at mold and cracking harm caused by storage area spills as well as ground moisture. When you need a good overall garage area flooring look, you are able to buy some wonderful significant duty paints that you are able to cover the concrete floors with.

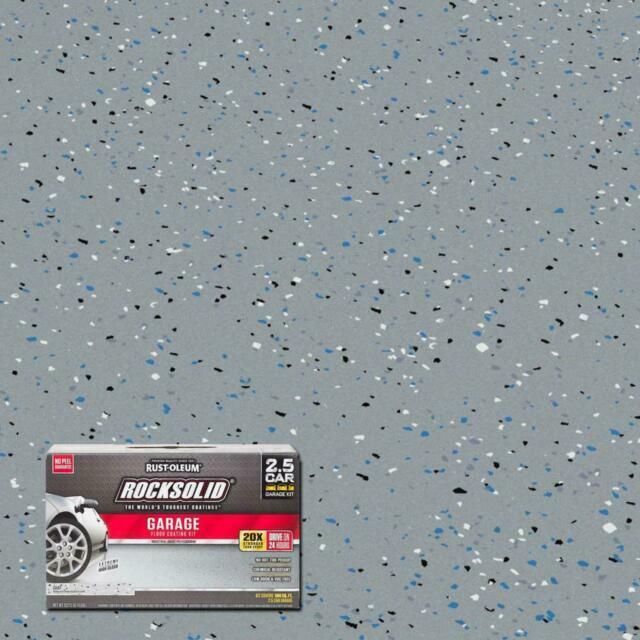

Images about Rock Solid Garage Floor Epoxy

Ordinarily, the garage floor is actually the last thing we think of when we pick out home improvement tasks. The garage floor of yours is ordinarily the most abused component of any structure, making the usage of garage flooring tiles a vital component of sustaining your clean, environment which is safe. An epoxy garage floor can withstand water, oil, dirt and grease without being harmed.

RockSolid Garage Coating: 1 Year Later // Part 3

Whatever type of garage flooring you opt for you need to be certain it will resist the kinds of materials or liquids you may expose it to. For the initial thirty days, do not use a power washer against your new garage floor paint to avoid any chipping. If you have a home in a bigger community you will be able to find some good showrooms to see several samples of the avenues.

How to Apply RockSolid Metallic Garage Floor Finish

Applying Rustoleum Rock Solid on My New Garage Floor – 50u0027 x 20

RockSolid® High-Gloss 1-Car Garage Floor Coating Kit – 90 oz. at

Garage Floor Makeover Rust-Oleum RockSolid Garage Floor Coating

We Review RockSolidu0027s Metallic Garage Floor Coating All Garage

So I re-did my garage floors with Rust-Oleum Rocksolid and : r

RockSolid Garage Floor Coating » Rogue Engineer Garage floor

How to Install Rust-Oleum RockSolid Metallic Garage Floor Coating

How to Apply Garage Floor Coating Rust-Oleum

Rust-Oleum 286879 Polycuramine Garage Floor Coating Kit – Gray for

Rock Solid Garage Floor – Bower Power Garage floor, Garage decor

RockSolid Garage Floor Coating Rust-Oleum

Related Posts:

- Garage Floor Tiles Design

- Large Garage Floor Mats

- Ferrari Garage Floor Tiles

- Garage Floor Coating Commercial

- Garage Floor Storm Shelter Cost

- Rustoleum Garage Floor Epoxy Shield

- Best Garage Floor Degreaser

- Garage Floor Rubber Paint

- Bright Red Garage Floor Paint

- Roll Out Garage Floor Covering

Rock Solid Garage Floor Epoxy: Creating a Durable and Attractive Surface

Introduction:

A garage floor is subjected to heavy foot traffic, vehicle movement, and exposure to various chemicals and substances on a daily basis. To withstand these challenges and maintain a clean and attractive appearance, it is essential to choose the right flooring solution. Rock Solid Garage Floor Epoxy is a popular choice among homeowners and commercial establishments due to its exceptional durability, easy maintenance, and aesthetic appeal. In this article, we will explore the various benefits of Rock Solid Garage Floor Epoxy, its application process, frequently asked questions, and more.

1. The Benefits of Rock Solid Garage Floor Epoxy:

Rock Solid Garage Floor Epoxy offers numerous advantages that make it an ideal choice for garage flooring.

a) Durability: This epoxy coating creates a rock-solid surface that can withstand heavy loads without cracking or chipping. It forms a strong bond with the concrete floor, providing excellent resistance against impact, abrasion, and chemical spills.

b) Easy Maintenance: Unlike traditional concrete floors that require constant cleaning and sealing, Rock Solid Garage Floor Epoxy is easy to maintain. Its seamless finish prevents dirt and stains from penetrating the surface, making it effortless to clean with just soap and water.

c) Aesthetic Appeal: With a wide range of colors and finishes available, Rock Solid Garage Floor Epoxy allows you to customize your garage floor according to your preferences. Whether you prefer a high-gloss shine or a more subtle matte finish, this epoxy coating enhances the overall aesthetics of your space.

d) Safety: One of the significant advantages of Rock Solid Garage Floor Epoxy is its slip-resistant properties. This coating can be enhanced with anti-skid additives that provide additional traction in wet or oily conditions, ensuring safety for both vehicles and pedestrians.

Frequently Asked Questions:

Q1: Can I apply Rock Solid Garage Floor Epoxy myself, or should I hire a professional?

A: While it is possible to apply Rock Solid Garage Floor Epoxy yourself, hiring a professional is recommended for optimal results. Professional installers have the necessary expertise and equipment to ensure a smooth and even application, minimizing the risk of bubbles or imperfections.

Q2: How long does it take for Rock Solid Garage Floor Epoxy to cure?

A: The curing time of Rock Solid Garage Floor Epoxy depends on various factors such as temperature and humidity levels. Generally, it takes approximately 24-48 hours for the epoxy to cure completely. However, it is advisable to wait at least 72 hours before subjecting the floor to heavy traffic or placing heavy objects on it.

2. The Application Process:

To achieve a flawless finish with Rock Solid Garage Floor Epoxy, proper preparation and application techniques are crucial. Here is a step-by-step guide to applying this epoxy coating:

Step 1: Surface Preparation

– Thoroughly clean the garage floor by removing any dirt, oil, or grease using a degreaser and scrub brush.

– Repair any cracks or damage in the concrete using a suitable filler.

– Etch the floor with an acid-based solution or mechanically grind it to create a rough surface for better adhesion.

Step 2: Applying the Primer

– Mix the primer according to the manufacturer’s instructions.

– Use a roller or brush to apply a thin and even coat of primer onto the prepared surface.

– Allow the primer to dry for the recommended time before Moving on to the next step. This usually takes around 4-8 hours, but refer to the manufacturer’s instructions for specific drying times.

Step 3: Mixing and Applying the Epoxy

– Thoroughly mix the epoxy coating according to the manufacturer’s instructions. This usually involves combining a resin and a hardener.

– Pour the mixed epoxy onto the floor in small sections, starting from one corner and working your way towards the exit.

– Use a roller or squeegee to spread the epoxy evenly, making sure to coat the entire surface.

– If desired, add any decorative flakes or chips while the epoxy is still wet for added texture and visual appeal.

Step 4: Allowing the Epoxy to Cure

– After applying the epoxy, allow it to cure for the recommended time. This typically takes around 24-48 hours, but refer to the manufacturer’s instructions for specific curing times.

– During this time, avoid walking or driving on the newly coated floor to prevent any damage or imperfections.

Step 5: Applying a Topcoat (Optional)

– If desired, apply a clear topcoat over the cured epoxy for added protection and durability. Follow the manufacturer’s instructions for mixing and applying the topcoat.

– Allow the topcoat to dry and cure according to the recommended time before using the garage space as normal.

Remember that proper preparation and following all manufacturer’s instructions are essential for achieving a successful application of Rock Solid Garage Floor Epoxy. It is always recommended to consult with professionals or contact customer support if you have any questions or concerns during the application process.