The floors don't chip off by the corners and there are no scratches. It is going to become the foundation for many locations. You will find a great deal of epoxy floor paints that can be purchased from hardware stores but many of these merely have some instructions regarding how to mix it. Epoxy flooring is the method of using tiers of epoxy resin over a floor's surface area, generally up to two mm thick.

Images about Self Leveling Floor Epoxy Home Depot

Making slip resistant floors is possible by employing appropriate additives to the epoxy compound mix. Part of the fascination designers have within epoxy flooring would be that as soon as completely dry, the floor will present a high, glossy shine. You don't need to replace your floors; you are able to easily enhance your concrete, etc with a bit of epoxy. This epoxy resin is clear, and can develop a glossy but non-slip area.

Rapid Set 50 lb. CTS Concrete Leveler 186010050

For the entryway, bath room, or maybe kitchen there are tiles that may be made of epoxy. Regardless of whether you wish to develop the ideal workplace or maybe a premier home decor, you will be happy with the results. An epoxy floors coating is usually installed easily, with minimal down time. The resin and hardener are actually combined together to chemically react.

Sika SikaLevel 50 lb. Self-Leveling Underlayment Concrete Floor

A number of epoxy floor coatings consist of pigments which expand fast when exposed to strong heat. One of the most widely used flooring choices for this niche is epoxy flooring. Epoxy formulations have been an essential aspect of the construction industry for fifty years. You will need to install a new coat over the damaged one. Resin & hardeners offer strength to the compound.

BEHR PREMIUM 1 gal. #P300-7 Unmellow Yellow Self-Priming 1-Part

WiseBond 1 gal. Clear Bar and Table Top Wood and Concrete 1:1

BEHR PREMIUM 1 gal. #BXC-55 Concrete Sidewalk Self-Priming 1-Part

Rapid Set 50 lb. CTS Concrete Leveler 186010050

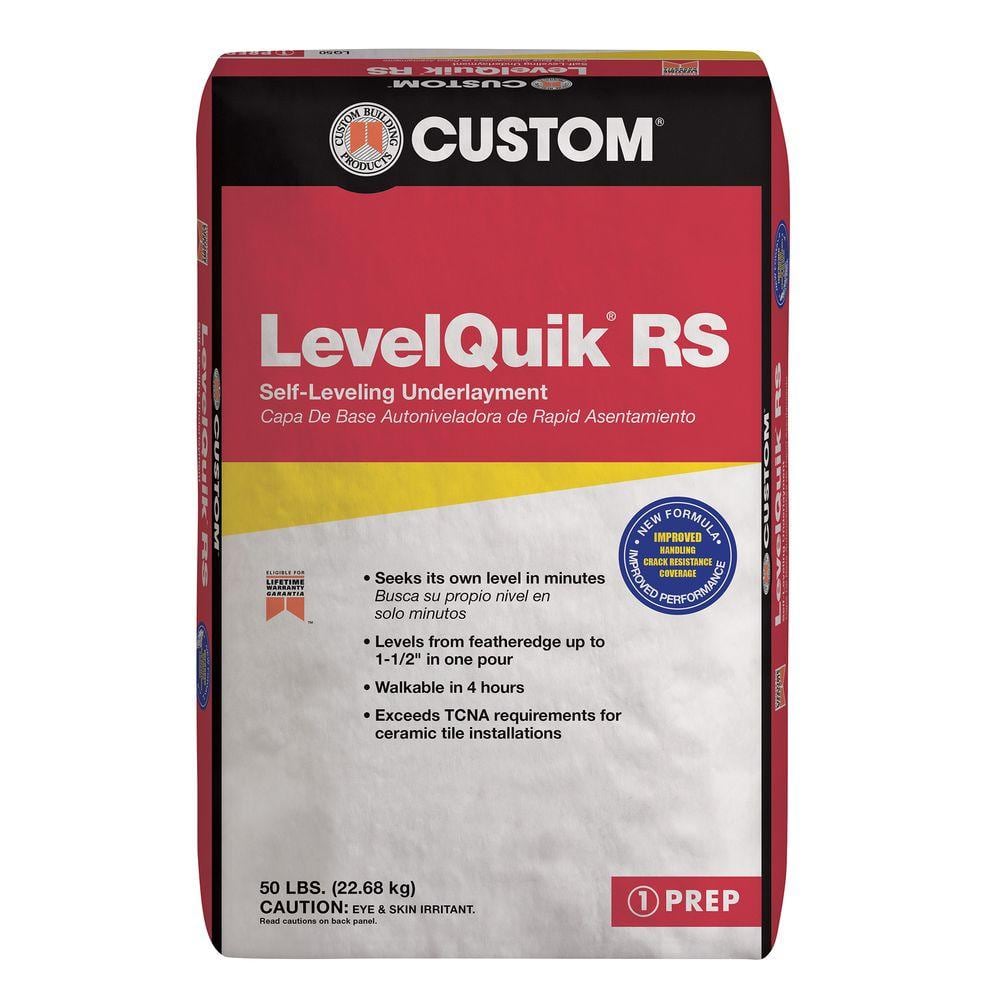

Custom Building Products LevelQuik 1 qt. Acrylic Primer CPQT

BEHR PREMIUM 1 gal. #N380-7 Black Bamboo Self-Priming 1-Part Epoxy

Rapid Set 50 lb. CTS Concrete Leveler 186010050

BEHR PREMIUM 1 gal. White Self-Priming 1-Part Epoxy Satin Interior

BEHR PREMIUM 5 gal. Slate Gray Self-Priming 1-Part Epoxy Satin

Rust-Oleum EpoxyShield 90 oz. Clear High-Gloss 2-Part Epoxy

Henry 555 Level Pro 40 lb. Self-Leveling Underlayment 12165

Related Posts:

- Best Epoxy Floor Covering

- How To Apply Epoxy To Concrete Floor

- Two Part Epoxy Floor Paint

- Epoxy Flooring For Food Processing

- Anti Static Epoxy Flooring Sika

- Painting Over Epoxy Floor

- How Much Does Epoxy Flooring For Garage Cost

- Marble Epoxy Floor Kit

- Acrylic Epoxy Floor Paint

- Flexible Epoxy Floor Coatings

Title: Self Leveling Floor Epoxy Home Depot: The Ultimate Solution for a Perfectly Smooth and Durable Flooring Surface

Introduction:

A well-designed and durable flooring surface can transform the aesthetics and functionality of any space. Self-leveling floor epoxy from Home Depot is an innovative solution that provides a seamless, smooth, and long-lasting finish to any flooring project. In this article, we will delve into the detailed features, benefits, application process, frequently asked questions, and more regarding self-leveling floor epoxy available at Home Depot.

I. Understanding Self-Leveling Floor Epoxy:

Self-leveling floor epoxy is a two-component resin system that combines epoxy resin and a hardening agent. This unique formulation allows the product to self-level and create a smooth, even surface when poured onto the floor. It is commonly used to resurface damaged or uneven concrete floors, providing a visually appealing and durable finish.

FAQs:

Q1: What makes self-leveling floor epoxy different from other flooring solutions?

A1: Unlike traditional floor coatings or paints, self-leveling floor epoxy has exceptional self-leveling properties. It can easily fill in cracks, divots, and other imperfections in the existing floor surface, creating a uniform finish. Moreover, its resistance to chemicals, abrasion, and impact makes it ideal for high-traffic areas.

Q2: Is self-leveling floor epoxy suitable for both residential and commercial applications?

A2: Yes, it is versatile enough to be used in various settings such as homes, offices, retail spaces, warehouses, and industrial facilities. Its durability ensures it can withstand heavy foot traffic and even vehicular movement in some cases.

II. Benefits of Self-Leveling Floor Epoxy:

1. Seamless Finish: Self-leveling floor epoxy creates a seamless surface without joints or grout lines. This feature makes it easy to clean while reducing the accumulation of dirt or bacteria. A seamless finish also enhances the visual appeal of the floor, giving it a sleek and modern look.

2. Durability: Home Depot’s self-leveling floor epoxy offers exceptional durability. It is highly resistant to chemicals, stains, impact, and abrasion, making it suitable for areas prone to spills or heavy equipment use. The robust nature of this flooring solution ensures longevity and reduces the need for frequent repairs or replacements.

3. Versatility in Design: With a wide range of colors, patterns, and finishes available at Home Depot, self-leveling floor epoxy allows for endless design possibilities. From solid colors to metallic effects, you can customize your flooring surface to match your desired aesthetic.

4. Easy Maintenance: Cleaning and maintaining a self-leveling floor epoxy surface is hassle-free. Its smooth finish prevents dirt and stains from penetrating the surface easily. Regular sweeping or mopping with mild detergents is sufficient to keep your floor looking pristine.

FAQs:

Q1: Can self-leveling floor epoxy be used outdoors?

A1: While self-leveling floor epoxy is primarily designed for indoor use, certain outdoor applications are possible. However, it is important to note that prolonged exposure to sunlight may cause color fading or yellowing over time.

Q2: How long does self-leveling floor epoxy last?

A2: When properly installed and maintained, self-leveling floor epoxy can last for many years. Factors such as foot traffic intensity and maintenance practices can influence its longevity.

III. Application Process:

1. Surface Preparation: Before applying self-leveling floor epoxy, the Existing floor surface must be thoroughly cleaned and prepared. This typically involves removing any dirt, debris, oil, or grease from the surface. Any cracks or damaged areas should be repaired before proceeding.

2. Primer Application: A primer may be necessary to ensure proper adhesion of the self-leveling floor epoxy. The specific primer required will depend on the type of substrate and the manufacturer’s recommendations. The primer is typically applied using a roller or brush and allowed to dry according to the instructions.

3. Mixing the Epoxy: The self-leveling floor epoxy is usually supplied in two components – resin and hardener. These components must be mixed together following the manufacturer’s instructions. It is important to mix them thoroughly to ensure proper curing and performance.

4. Pouring and Spreading: Once the epoxy is mixed, it should be poured onto the prepared floor surface. It is important to work quickly as the epoxy has a limited working time. Using a squeegee or trowel, spread the epoxy evenly across the surface, allowing it to self-level and fill in any imperfections.

5. Curing and Drying: After application, the self-leveling floor epoxy needs time to cure and dry. The curing time can vary depending on factors such as temperature and humidity. It is important to allow sufficient drying time before subjecting the floor to foot traffic or other stress.

6. Optional Topcoat: Depending on your desired finish and level of protection, a topcoat may be applied over the cured self-leveling floor epoxy. This can provide additional durability, chemical resistance, and aesthetic enhancements.

Note: It is recommended to follow the specific instructions provided by the manufacturer of the self-leveling floor epoxy product being used.