Besides a mirror like gloss, concrete flooring may be spruced up with embedded other, grids, images, lines, and patterns designs. They impart a luxurious richness that can't be attained by any other flooring. With more properties being built in a modern style, concrete polishing floors is growing in leaps and bounds. Coarse pads file down the top surface area of the concrete.

Images about Sloping Existing Concrete Floor

The floor could be dyed just about any color and area glow can be anywhere you want to between a matte finish to a high gloss. Individuals who are vulnerable to allergies could easily make use of concrete flooring in their house. Technological advancements have made polished concrete floor one particular of the good opposition and at existing, you can look forward to get a few spectacular floors.

How to Make a Concrete Subfloor Leveling with Sloping Down Side DIY MrYoucandoityourself

The color of the tile might be used as the very same color to spot the concrete floors. Concrete floors are hard and durable. The concrete floors is there to stay and when you move on at a bit of point, the new owners will have the ability to enjoy the benefits this kind of flooring provides. Nearly all common flooring have arduous cleaning requirements.

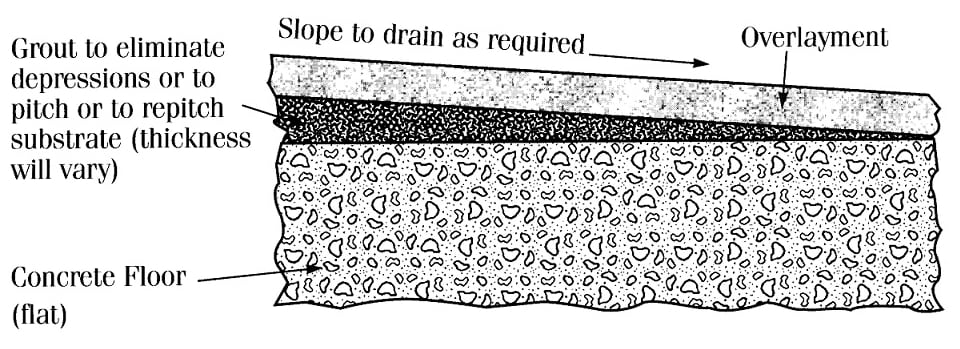

Slope Concrete To Drain Design u0026 Construction For Industrial

Self-Leveling Concrete Can Save Both Time and Money – Concrete Decor

How to Level a Sloped, Uneven Concrete Floor

How to Add Concrete to Existing Concrete (with Pictures) – wikiHow

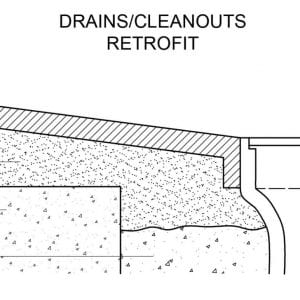

Insulation Retrofit for an Existing Concrete Slab and 2×4 Walls

How to create pitch/slope in a cured cement slab?? Hometalk

Installing Rigid Foam Above a Concrete Slab – GreenBuildingAdvisor

How to Level a Concrete Patio

How to Cut a Drainage Channel into a Concrete Slab

Topping Concrete – Work Procedure, Types and Advantages – The

Proper Slope For Drainage: Industrial Processing Facilities EP

Proper Slope For Drainage: Industrial Processing Facilities EP

Related Posts:

- How To Finish A Concrete Floor With A Power Trowel

- Laying Dpm Concrete Floor

- Concrete Floor Primer For Vinyl Tiles

- Concrete Floor Price Estimate

- Concrete Floor Paint Stain

- How To Finish Concrete Floors Indoors

- Concrete Floor Washing Machine

- How To Stain And Seal Concrete Floors

- Stain Concrete Floor To Look Like Wood

- Painting A Concrete Floor In Basement

Sloping Existing Concrete Floors: An In-Depth Guide

Creating a sloped concrete floor can not only offer aesthetic benefits but also practical ones. Sloping concrete floors can help protect against water and moisture damage, as well as provide improved drainage. However, creating a sloped concrete floor is not always as simple as it sounds, so it’s important to understand the process and the best practices to ensure your project is successful.

In this guide, we’ll cover the basics of sloping existing concrete floors, including what equipment you’ll need, the steps involved in getting your project done, and some helpful tips for ensuring a successful outcome.

Equipment Needed for Sloping Existing Concrete Floors

Before you start your project, you’ll need to make sure you have the right equipment for the job. Depending on the size and scope of your project, you may need a variety of tools and materials. Here’s a list of essential items you’ll need:

– Hammer drill

– Masonry drill bit

– Circular saw

– Chalk line

– Measuring tape

– Level

– Cement mix

– Wheelbarrow

– Shovel or trowel

– Mortar mix

– Concrete sealer

– Polyurethane foam filler (optional)

Steps for Sloping Existing Concrete Floors

The process for creating a sloped concrete floor can vary depending on the size and complexity of your project. However, here are some general steps that you can take to get your project done:

1. Begin by measuring the area that needs to be sloped and marking off any areas that don’t need to be worked on. You should also measure and mark any areas where there will be changes in slope or angle. This will help ensure accuracy when working on your project.

2. Use a hammer drill and masonry bit to bore holes into the existing concrete floor. The holes should be spaced evenly throughout the area and should be deep enough to provide secure footing for any new material you plan to add.

3. Use a circular saw to cut away any areas that don’t need to be worked on or that are too close to existing walls or pillars. Be sure to use safety goggles when cutting concrete with a saw.

4. Once all of the necessary cuts have been made, use a chalk line to mark off the edges of any slopes or angles in the area that are being worked on. This will help ensure accuracy when laying down new material.

5. Measure out the desired depth of each slope or angle and use a level to verify that it is correct before beginning work with cement mix or mortar mix.

6. Before adding new material, make sure that all surfaces are clean and free from debris or dirt which could interfere with adhesion between materials.

7. Once everything has been prepared, begin adding new material such as cement mix or mortar Mix. Be sure to follow the manufacturer’s instructions for mixing and application.

8. Use a trowel or shovel to shape the newly applied material into the desired slope or angle. Allow it to set for the recommended time before continuing work on the project.

9. Once the new material has had time to cure, use a concrete sealer to protect it from moisture and weather damage.

10. Optionally, you can use polyurethane foam filler to fill in any cracks or gaps that may have formed while working on your project.

Tips for Sloping Existing Concrete Floors

Working with concrete can be tricky, but there are some steps you can take to ensure that your project goes as smoothly as possible:

– Take your time when measuring and marking off areas for your project. Making mistakes at this stage can cause major issues later on in the process, so it’s important to double and triple check your measurements before beginning work.

– When drilling holes into existing concrete, be sure to use a hammer drill and masonry bit specifically designed for concrete applications. Don’t attempt to use regular drill bits as this could cause major damage to the existing surface.

– When mixing cement mix or mortar mix, be sure to follow the instructions provided by the manufacturer. Not following directions could lead to an uneven surface or poor adhesion between materials.

– Allow plenty of time for the new material to cure before walking on it or applying sealant. Not allowing enough time could cause issues down the line.

By following these steps and tips, you should be able to successfully slope existing concrete floors with ease!