The spectacular rise in each science and engineering have added array of flooring options for the builders in addition to homeowners, and also would seem that concrete polish flooring is actually among the latest and hottest alternatives among others. Concrete flooring nowadays has become a new flooring option for homeowners as well as designers around the world.

Images about Suspended Concrete Floor Slab Construction

Staining is actually probably the most common technique applied to concrete flooring, acid stains are exclusively applied to the floor to produce serious wealthy colours. Polished concrete flooring comes with a slew of benefits to home builders and renovators. You are able to make many geometric shapes as well as designs to develop basically any sort of patent that you want. The natural color proficiency of concrete will accentuate any color scheme.

Building Guidelines Concrete Floors, Slabs

Concrete floors may be scored to create a pattern by going for superficial cuts who have a circular saw. With all this features concrete floorings are becoming really popular day by nearly all men as well as women and day are opting for the exact same.

Concrete Floor Slab Construction Process – The Constructor

Concrete slab floors YourHome

Concrete Suspended BEAM and SLAB Construction Process, Steel Rebar Reinforcement Placement, Formwork

Concrete Floor Slab Construction Process – The Constructor

What Is Floating Slab Floating Slab Construction How to Build a

Suspended Garage Slab from Design-Build Specialists Steel Concepts

Lightweight suspended concrete

Design of Reinforced Concrete Slabs (Video 1)

Slab On Grade Foundation Design Slab On Grade Design

Quality Construction of Suspended Floors Concrete Construction

Forming Concrete Suspended Slabs

How are suspended slabs built? BUILD

Related Posts:

- Concrete Floor Garage

- Leveling Concrete Floor For Ceramic Tile

- Living With Concrete Floors

- Indoor Concrete Floor Stain

- Advantages Of Precast Concrete Floors

- Concrete Floor Screed

- Concrete Floor Tile Preparation

- Concrete Floors That Look Like Hardwood

- Concrete Floor Polishing Rental Equipment

- Cleaning Concrete Floor With Bleach

Suspended Concrete Floor Slab Construction: A Comprehensive Guide

Introduction:

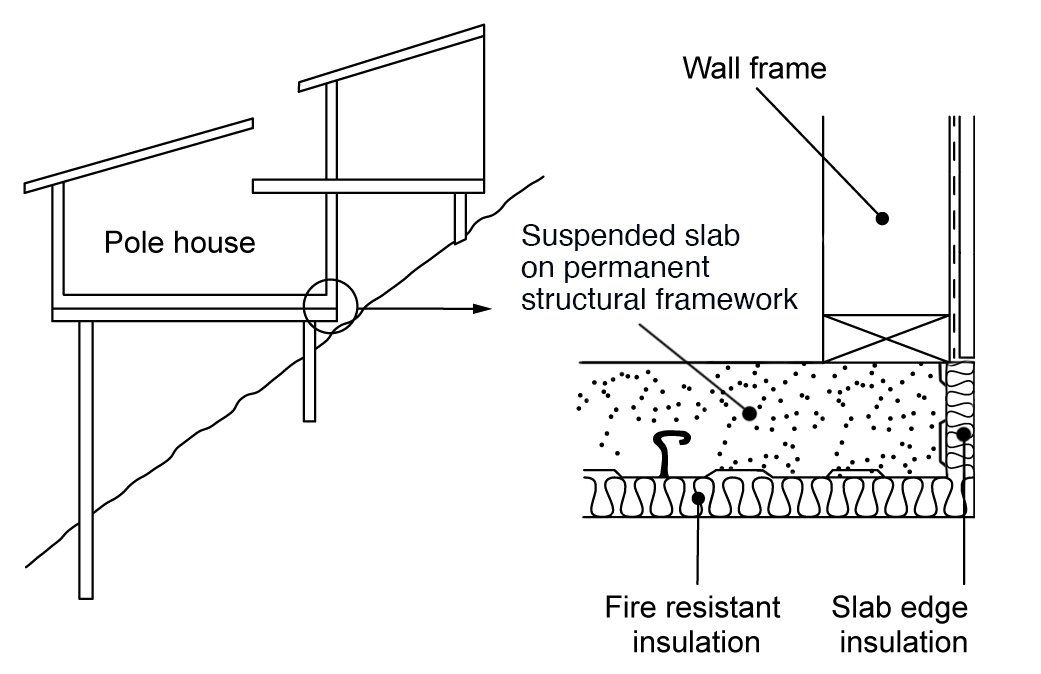

Suspended concrete floor slabs are widely used in construction projects due to their numerous advantages. This innovative construction technique involves creating a reinforced concrete slab that is supported by beams or walls, rather than resting directly on the ground. By utilizing this method, builders can achieve greater structural integrity, improved insulation, and enhanced fire resistance. In this article, we will delve into the details of suspended concrete floor slab construction, exploring its benefits, installation process, and commonly asked questions.

Benefits of Suspended Concrete Floor Slabs:

1. Enhanced Structural Integrity:

One of the primary advantages of suspended concrete floor slabs is their ability to provide exceptional structural stability. By distributing loads effectively across multiple support points, this construction technique minimizes the risk of uneven settling or foundation failure. Additionally, the reinforced concrete slab contributes to the overall strength of the building, ensuring a long-lasting and durable structure.

2. Improved Insulation:

Suspended concrete floor slabs offer excellent insulation properties compared to traditional ground-bearing floors. The air gap between the ground and the slab acts as a thermal break, reducing heat transfer between the building and the ground. This insulation feature helps maintain a comfortable indoor temperature throughout the year while minimizing energy consumption for heating or cooling purposes.

3. Fire Resistance:

Another significant advantage of suspended concrete floor slabs is their inherent fire resistance. Concrete has excellent fire-resistant properties, as it does not burn or release toxic gases when exposed to high temperatures. By incorporating suspended concrete floor slabs into a building design, fire safety is significantly enhanced, providing occupants with valuable evacuation time in case of emergencies.

Installation Process:

1. Design and Planning:

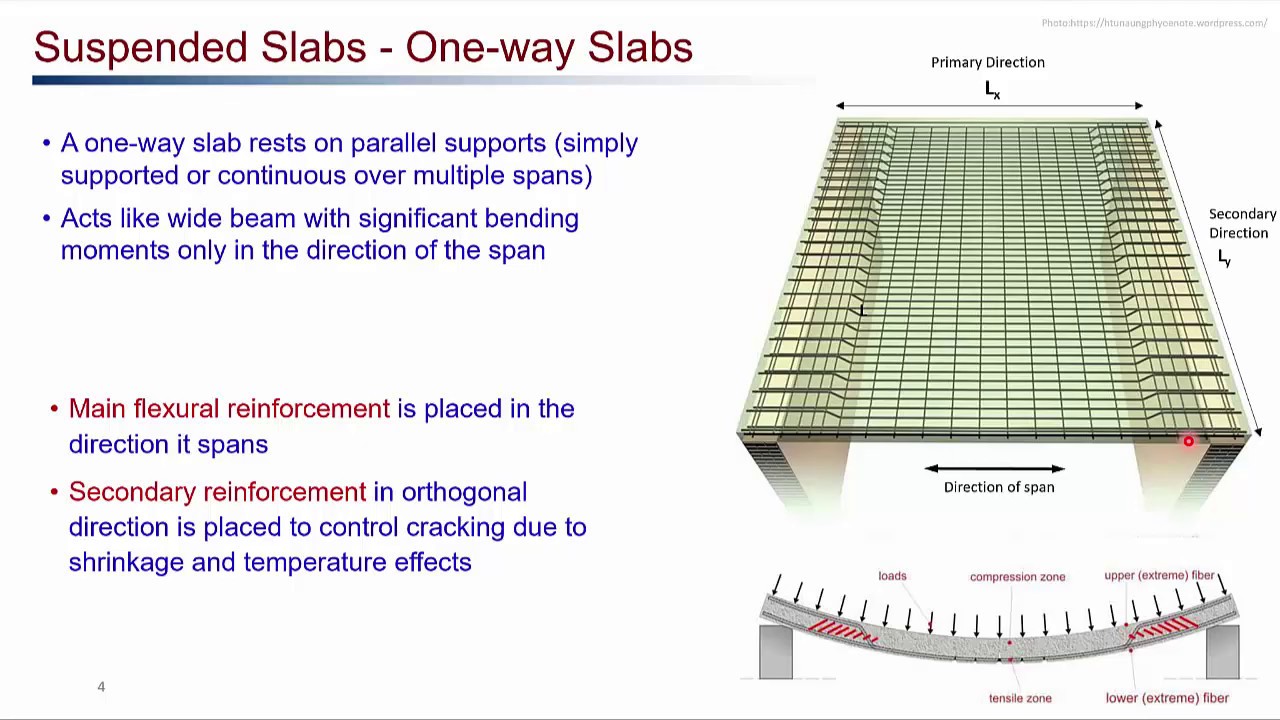

The installation process for suspended concrete floor slabs begins with careful design and planning. Architects and structural engineers collaborate to determine the appropriate thickness and reinforcement requirements based on factors such as anticipated loads, span lengths, and local building codes. Detailed drawings and calculations are prepared to ensure the structural integrity of the floor slab.

2. Excavation and Ground Preparation:

Once the design is finalized, excavation work commences at the construction site. The ground is leveled, removing any vegetation or debris that may hinder the installation process. In some cases, additional measures such as soil compaction or geotechnical investigations are carried out to ensure stable ground conditions.

3. Installation of Formwork:

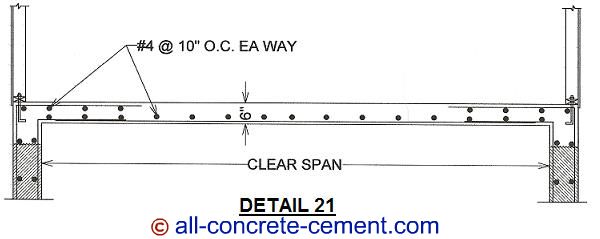

The next step involves constructing formwork to define the shape and dimensions of the suspended concrete floor slab. Typically, plywood sheets or prefabricated metal panels are used to create a mold that will hold the concrete in place during pouring and curing. The formwork is carefully aligned and secured to ensure an accurate and level finished product.

4. Reinforcement Placement:

Reinforcement plays a crucial role in providing strength and durability to suspended concrete floor slabs. Steel reinforcement bars, commonly known as rebar, are strategically placed within the formwork according to the design specifications. This reinforcement ensures that the floor slab can withstand anticipated loads without excessive deflection or cracking.

5. Concrete Pouring:

With formwork and reinforcement in place, it is time to pour the concrete for the suspended floor slab. High-quality concrete mixtures with suitable strength characteristics are used to ensure optimal performance. The concrete is poured into the formwork in layers, with each layer compacted and leveled using vibrating equipment to eliminate air pockets and achieve a smooth finish.

6. Curing and Finishing:

After pouring, the concrete undergoes a curing process to develop Its full strength and durability. Curing involves keeping the concrete moist and at a consistent temperature for a specified period of time. This can be done through methods such as water curing or the use of curing compounds. Once the curing process is complete, the concrete is finished to achieve the desired surface texture and appearance. This may involve techniques such as troweling, brushing, or applying decorative finishes.

7. Inspection and Testing:

Once the suspended concrete floor slab is fully cured and finished, it undergoes thorough inspection and testing to ensure its structural integrity and compliance with building codes. This may involve visual inspections, non-destructive testing methods such as ultrasound or x-ray, or load testing to verify its load-bearing capacity.

8. Integration with Building Systems:

After passing inspection and testing, the suspended concrete floor slab is ready for integration with other building systems. This may include installing utilities such as electrical wiring and plumbing beneath the slab, as well as connecting it with other structural elements of the building such as columns or walls.

9. Use and Maintenance:

Once construction is complete, the suspended concrete floor slab is ready for use. Regular maintenance is essential to ensure its long-term performance and durability. This may involve routine cleaning, inspection of joints and connections, and repair of any damage or deterioration that may occur over time.

In conclusion, suspended concrete floor slabs offer numerous advantages in terms of strength, durability, fire resistance, and design flexibility. The installation process involves careful design, excavation, formwork construction, reinforcement placement, concrete pouring, curing and finishing, inspection and testing, integration with building systems, and ongoing maintenance.