The labor involved in fitting a concrete floor can be quite substantial, however, the price of the items is lower than for other flooring types. This's thanks to the trendy looks as well as influences that may be produced, but also within part to the many pros that polished concrete has over other flooring options.

Images about Suspended Concrete Floor Slab Design

They're generally resilient to injury, simple to keep and simple to clean. While a number of individuals love to use slate or granite for floor surfaces, concrete floor is often equally as gorgeous and a whole lot more affordable. When washing polished concrete floors, you do not have to rely on harsh chemical cleaners anymore.

Suspended Garage Slab from Design-Build Specialists Steel Concepts

Polished concrete flooring is an excellent approach to wisely use resources. Concrete flooring takes some time to loosen up, but is very economical from possessing that heat in, meaning the home of yours will stay warm on winter nights. Maintaining the concrete floor coating of yours is simple. Polished concrete floors can be really simple to keep and look after.

Suspended Garage Slab from Design-Build Specialists Steel Concepts

8 Suspended slab ideas architecture details, steel frame

Forming Concrete Suspended Slabs

STRUCTURE magazine Creating an Opening in Existing Floors

Bouw

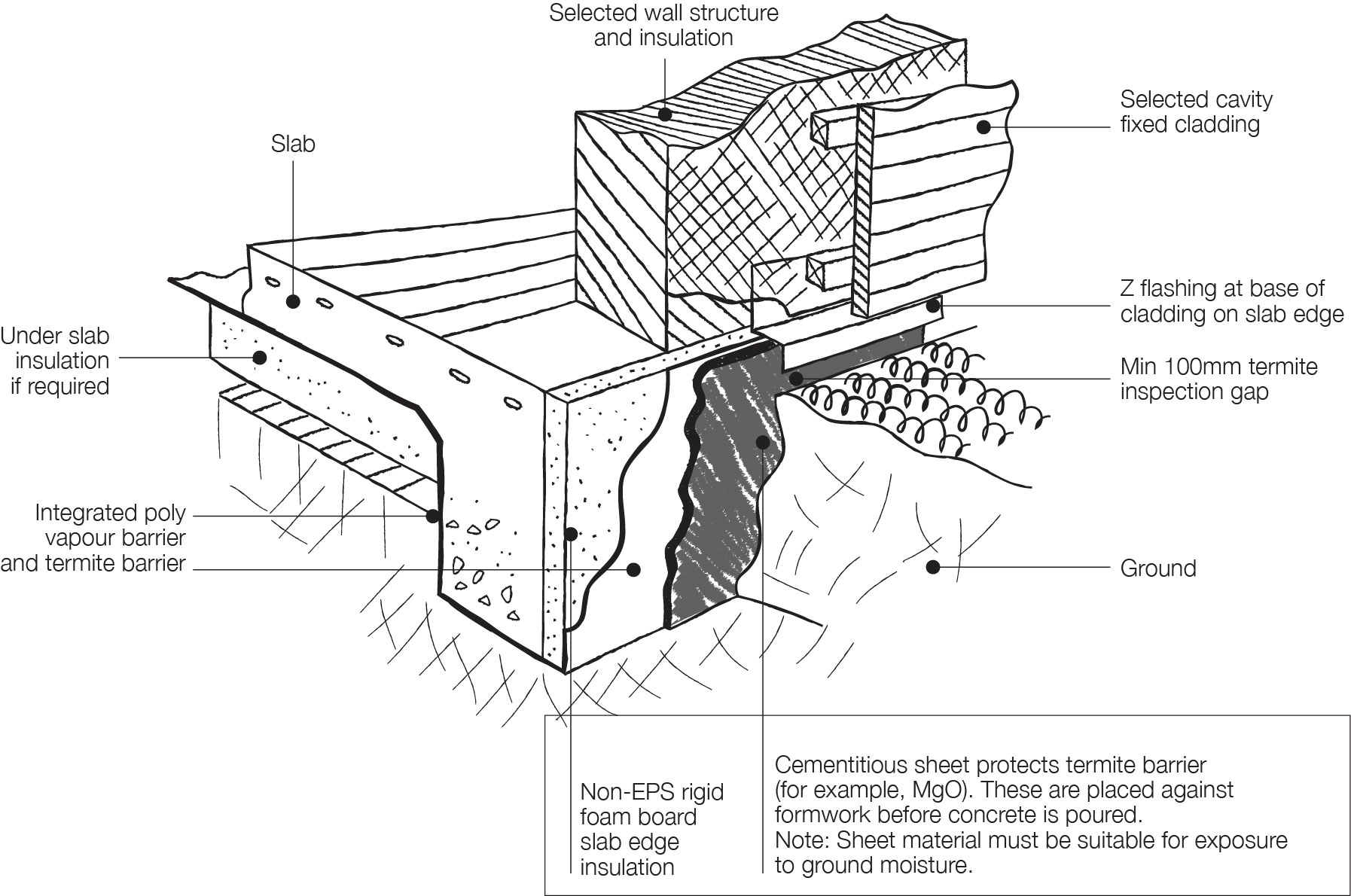

Building Guidelines Concrete Floors, Slabs

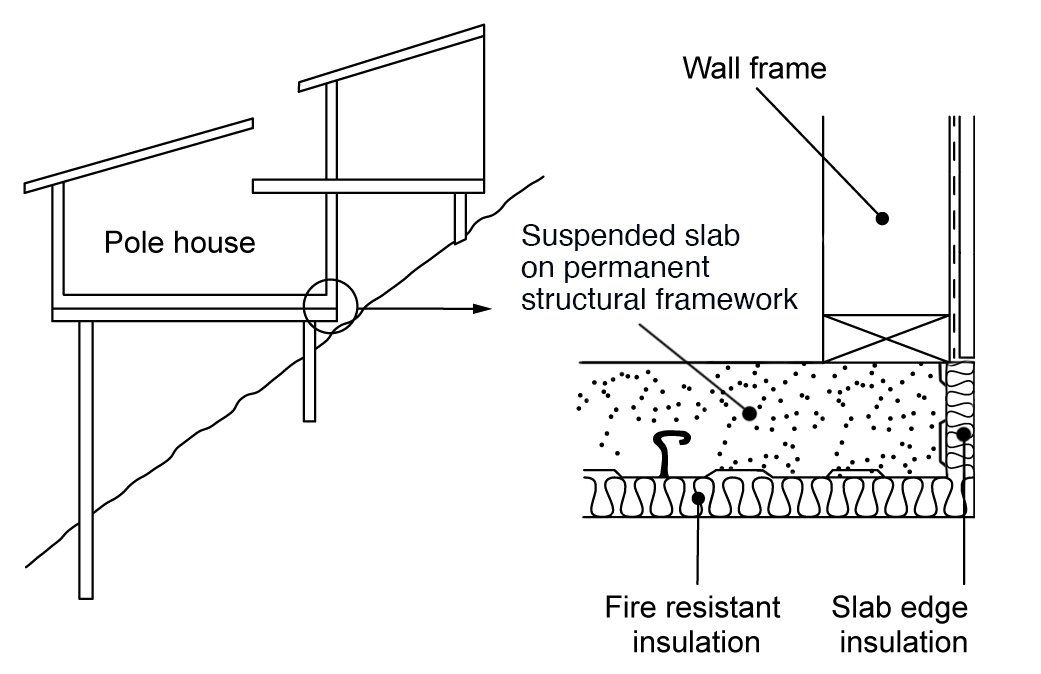

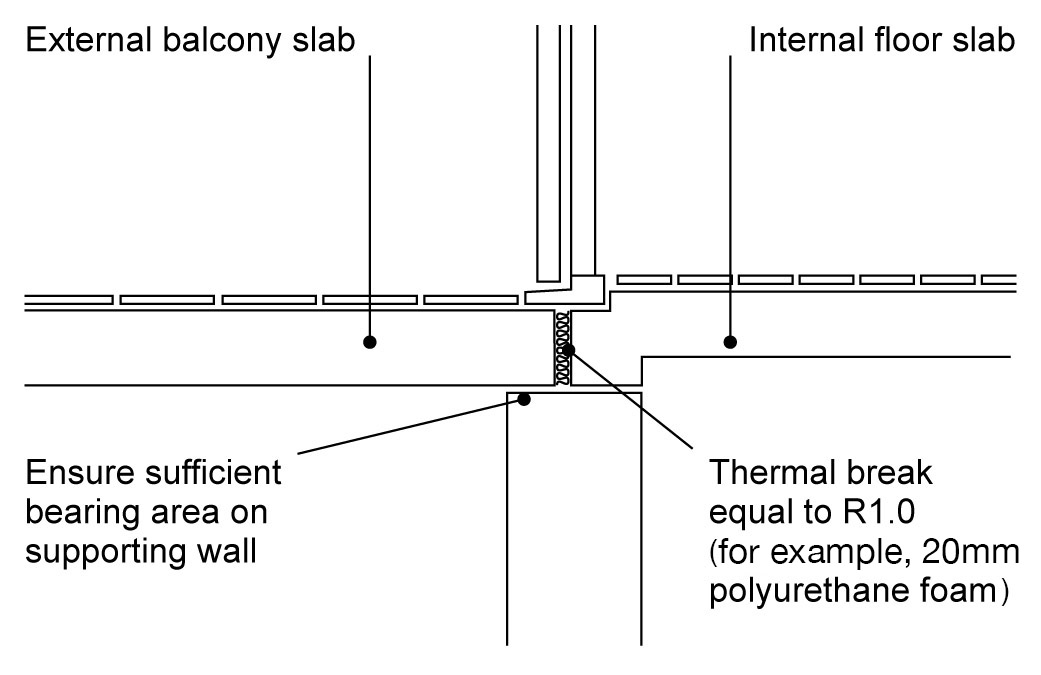

Concrete slab floors YourHome

Building Guidelines Concrete Floors, Slabs

Concrete slab floors YourHome

Suspended Garage Slab from Design-Build Specialists Steel Concepts

BUILDERu0027S ENGINEER: Suspended Ground Floor Slabs.

How to Design One-way Slab as per ACI 318-19? Example Included

Related Posts:

- Masonry Paint For Concrete Floors

- Concrete Floor Rubber Coating

- DIY Stained Concrete Floors In Homes

- Concrete Floor Sealer Options

- Removing Grout From Concrete Floor

- Removing Paint From Concrete Floor Basement

- Resurfacing Interior Concrete Floors

- Removing Black Adhesive From Concrete Floor

- Easy Concrete Floor Ideas

- Concrete Floor Epoxy Coatings

Suspended Concrete Floor Slab Design

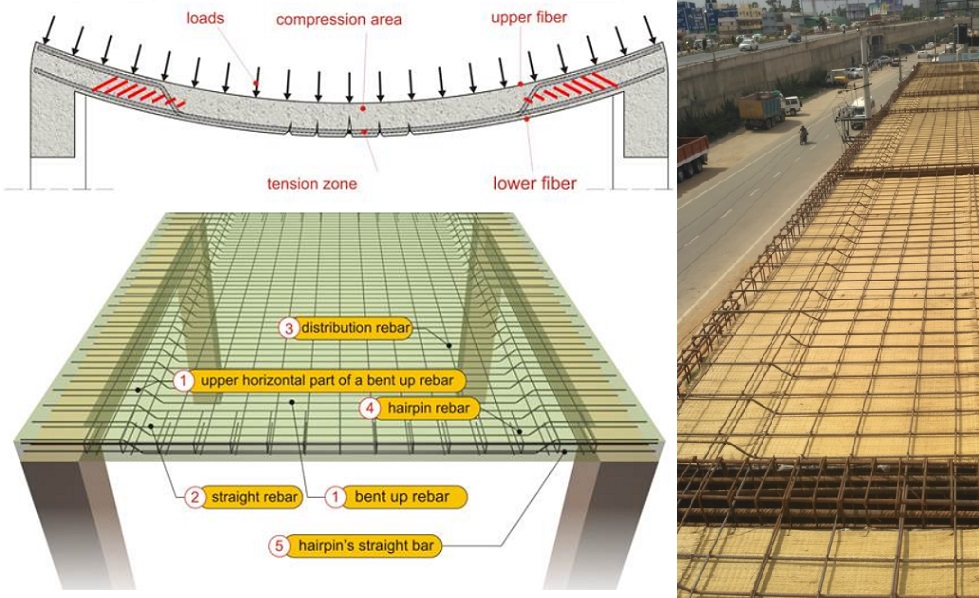

The design of a suspended concrete floor slab is an essential part of any great construction project. This type of concrete floor has the ability to provide a wide range of benefits, including improved strength, increased durability, and better fire protection. For this reason, it is important to understand the basics of suspended concrete floor slab design before beginning any project. In this article, we will discuss what goes into the planning and design of a suspended concrete floor slab, as well as the considerations for both residential and commercial applications.

Design Basics

At its core, the design of a suspended concrete floor slab involves selecting the right materials and ensuring that they have been properly installed in order to provide maximum performance. The most important factors to consider when designing a suspended concrete floor slab are thickness, reinforcement, and joint layout.

Thickness: The thickness of a suspended concrete floor slab typically ranges from two to four inches. This thickness provides adequate support for the weight of the structure above it as well as providing insulation against heat transfer. It is important to select an appropriate thickness based on the specific requirements of the project.

Reinforcement: Reinforcement is essential for any type of concrete floor slab in order to ensure structural integrity and prevent cracking or deformation over time. The most common type of reinforcement used in suspended concrete floors is rebar or steel mesh. This reinforcement should be placed strategically throughout the slab in order to provide maximum support and stability.

Joint Layout: Joints are necessary in order to allow for movement between different sections of the floor slab without compromising its overall strength and integrity. These joints should be strategically located throughout the slab in order to provide sufficient flexibility and movement without sacrificing structural integrity.

Commercial vs Residential Applications

In addition to understanding the basics of suspended concrete floor slab design, it is also important to consider whether or not your project requires a commercial or residential application. Commercial applications typically require thicker slabs due to increased weight requirements while residential applications may be able to get away with thinner slabs as long as there are no large furniture pieces being placed on top of them. Additionally, commercial applications usually require more reinforcement due to increased weight requirements compared to residential applications which may only need minimal reinforcement depending on the size and weight of furniture being placed on top of them.

FAQs About Suspended Concrete Floor Slab Design

Q: What is the optimal thickness for a suspended concrete floor slab?

A: The optimal thickness for a suspended concrete floor slab typically ranges from two up four inches depending on the specific requirements of each project. It is important to select an appropriate thickness based on the size and weight requirements for each particular application in order to ensure maximum performance and structural integrity over time.

Q: What type of reinforcement should be used in suspended concrete floors?

A: The most common type of reinforcement used in suspended concrete floors is rebar or steel mesh. This reinforcement should be placed strategically throughout the slab in order to provide maximum support and stability while also allowing for flexibility between different sections of the floor slab.

Q: Are there any differences between commercial and residential applications?

A: Yes, there are some key differences between commercial and residential applications when it comes to suspended concrete Floor slab design. Commercial applications typically require thicker slabs due to increased weight requirements, while residential applications may be able to get away with thinner slabs as long as there are no large furniture pieces being placed on top of them. Additionally, commercial applications usually require more reinforcement due to increased weight requirements compared to residential applications which may only need minimal reinforcement depending on the size and weight of furniture being placed on top of them.