Bear in mind concrete flooring can be covered with a number of substances such as epoxy, a lovely durable finish that can be used anyplace in the home. Concrete office flooring is a green colored option which frequently outlasts other floor types as carpet, tile, wood, and linoleum.

Images about Suspended Concrete Floor Slab Specifications

They are generally resilient to injury, simple to maintain and simple to clean. While some persons like to use slate or granite for flooring surfaces, concrete floor is equally as beautiful and a lot less costly. When cleaning polished concrete floor surfaces, you do not have to rely on harsh chemical cleaners anymore.

Building Guidelines Drawings. Section B: Concrete Construction

Polished concrete floors are now being noticed while the faster subject matter that is actually both highly useful and even decorative for public structures. You can blend it in various other surfaces to compliment your flooring option. Buyers often have various preferences. The notion of a lifeless grey concrete floors has been replaced with exquisite surfaces that could look as granite, marble, and even tile.

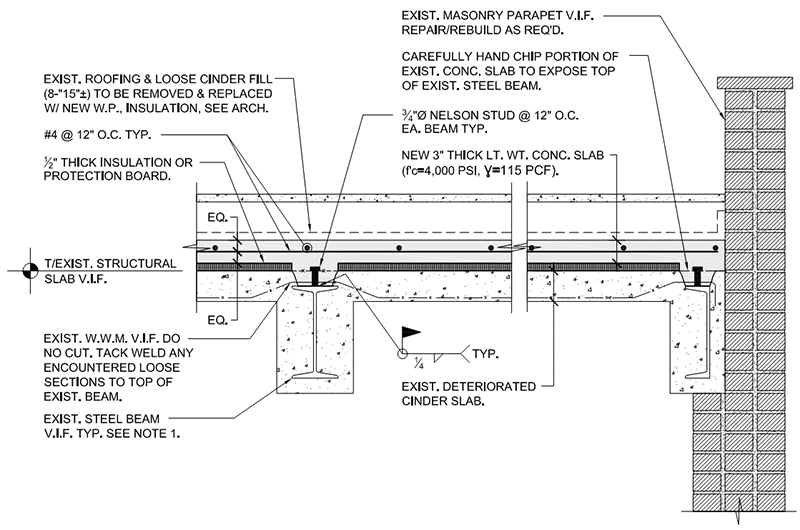

STRUCTURE magazine Cinder Concrete Slab Construction

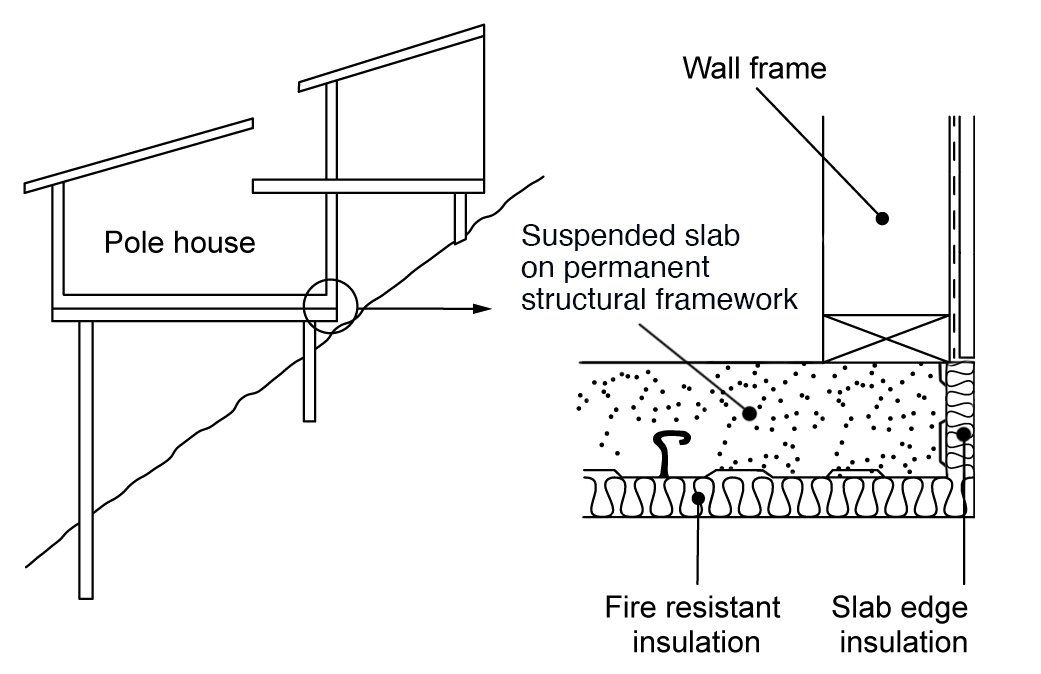

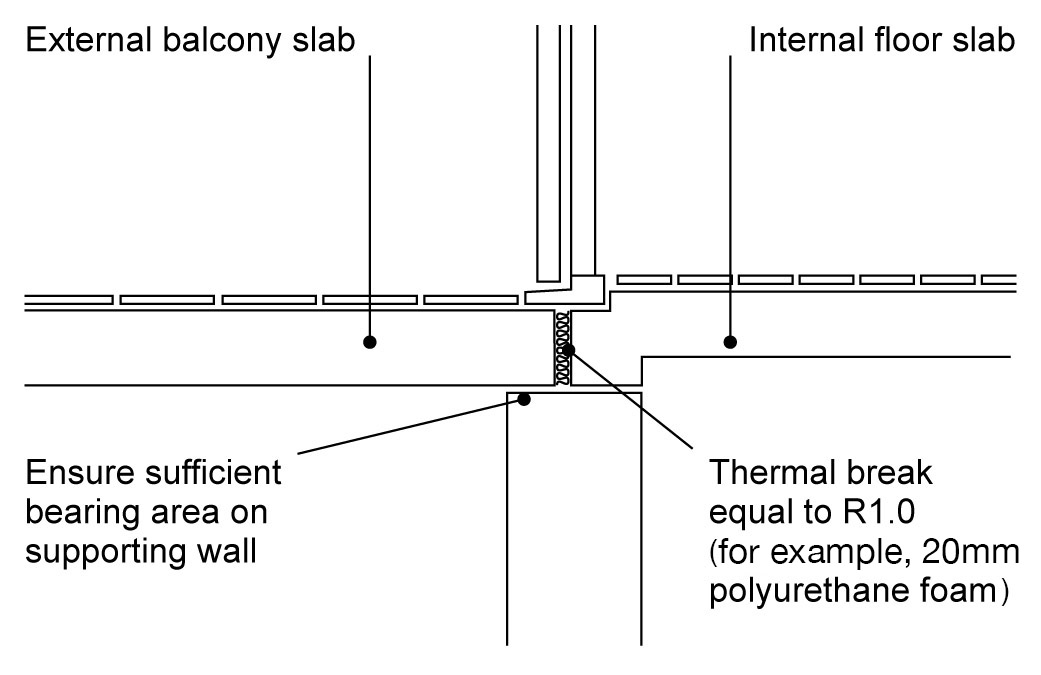

Concrete slab floors YourHome

6. Ground Floors – Construction Studies

Concrete Floor Slab Construction Process – The Constructor

Concrete slab floors YourHome

Floor systems – SteelConstruction.info

BUILDERu0027S ENGINEER: Suspended Ground Floor Slabs.

Slab On Grade Foundation Design Slab On Grade Design

Building Guidelines Drawings. Section B: Concrete Construction

Building Guidelines Drawings. Section B: Concrete Construction

Concrete slab floor construction BRANZ Renovate

FBE 03 Building Construction Science Lecture 3 Floor

Related Posts:

- Removing Porcelain Tile From Concrete Floor

- Scored Concrete Floor Designs

- Grey Concrete Floors

- Trimix Concrete Flooring Specifications

- Cracks In Concrete Floor In Garage

- DIY Concrete Floor Cleaner

- Easiest Way To Paint Concrete Floors

- Polished Concrete Floors In Homes Images

- Staining Old Concrete Floors

- Concrete Floor Tiles Bathroom

Suspended Concrete Floor Slab Specifications: A Comprehensive Guide

Introduction:

A suspended concrete floor slab is a widely used construction method that offers numerous advantages in terms of durability, strength, and cost-effectiveness. It involves the installation of a concrete slab supported by beams or walls, providing a solid foundation for various structures such as residential buildings, commercial complexes, and industrial facilities. In this article, we will delve into the specifications of suspended concrete floor slabs, exploring key components, construction techniques, design considerations, and frequently asked questions.

1. Components of Suspended Concrete Floor Slab:

A suspended concrete floor slab consists of several essential components that contribute to its structural integrity and performance. These include:

a) Concrete Mix Design:

The selection of an appropriate concrete mix design is crucial to ensure the desired strength and durability of the floor slab. Factors such as the required load-bearing capacity, exposure conditions, and specific project requirements should be considered when determining the mix proportions.

b) Reinforcement:

Reinforcement plays a vital role in enhancing the tensile strength of the concrete slab. Steel bars or mesh are commonly used to reinforce the floor slab, effectively distributing loads and preventing cracks or failures. The amount and spacing of reinforcement depend on the anticipated loads and design specifications.

c) Formwork:

Formwork serves as temporary molds for pouring and shaping the concrete slab. It must be carefully designed and installed to withstand the weight of wet concrete and maintain accurate dimensions during curing. Typically constructed using timber or steel, formwork ensures proper alignment and finish of the suspended floor.

2. Construction Techniques:

The construction of a suspended concrete floor slab involves several key techniques that ensure its structural stability and longevity. These techniques include:

a) Beam-and-Block System:

In this widely adopted method, precast concrete beams are laid across walls or supports at regular intervals. The gaps between beams are then filled with precast concrete blocks or lightweight infill units. This system offers a rapid construction process, versatility in design, and efficient load distribution.

b) Ribbed Slab Construction:

Ribbed slabs, also known as waffle slabs, employ a grid of ribs or beams that are cast integrally with the slab. The ribs significantly reduce the weight of the floor slab while maintaining its strength. Ribbed slabs are particularly suitable for large spans and heavy loads, providing excellent thermal and sound insulation.

c) Hollow Core Slab:

Hollow core slabs consist of precast concrete elements with continuous voids running through their length. These voids not only reduce the weight of the slab but also allow for the passage of services such as electrical wiring and plumbing. Hollow core slabs offer rapid installation, excellent fire resistance, and enhanced sound insulation properties.

3. Design Considerations:

Designing a suspended concrete floor slab requires careful consideration of various factors to ensure structural adequacy and compliance with relevant codes and regulations. Key design considerations include:

a) Load Requirements:

The anticipated loads on the floor slab, including dead loads (self-weight, finishes) and live loads (occupancy, furniture), must be accurately determined. Structural engineers use industry standards and guidelines to calculate these loads, ensuring the floor slab can safely support them without excessive deflection or failure.

b) Span Length:

The span length refers to the distance between supports or beams. It significantly influences the design of the floor slab, as longer spans require additional reinforcement to resist bending and minimize deflection. Structural engineers consider factors such as building layout, Column spacing, and load requirements when determining the appropriate span length for a suspended concrete floor slab.

c) Deflection Control:

Deflection refers to the downward displacement or bending of a floor slab under load. Excessive deflection can lead to cracks, uneven surfaces, and discomfort for occupants. Designers must consider deflection limits specified in building codes and ensure the floor slab is adequately reinforced to control deflection within acceptable limits.

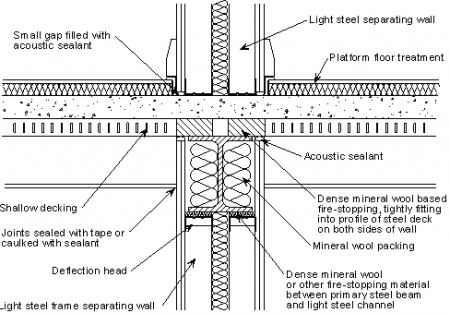

d) Thermal and Acoustic Performance:

Suspended concrete floor slabs can significantly impact thermal and acoustic performance within a building. Designers may incorporate insulation materials, such as rigid foam boards or mineral wool, to enhance thermal insulation. Additionally, measures like adding resilient layers or using sound-absorbing materials can improve acoustic performance by reducing noise transmission between floors.

e) Fire Resistance:

Fire resistance is a critical consideration for suspended concrete floor slabs, especially in multi-story buildings. Structural engineers must design the slab to withstand fire exposure for a specified period. This may involve using fire-resistant materials, such as concrete with added fire-resistant additives or incorporating additional fire protection measures like fireproof coatings or fire barriers.

In conclusion, designing and constructing a suspended concrete floor slab involves careful planning, selection of appropriate construction techniques, and consideration of various design factors. By following industry standards and guidelines, professionals can ensure the structural integrity, durability, and functionality of these essential building elements.