The trend seems to be for homeowners to purchase wood flooring with a factory applied finish. If perhaps you are a do-it-yourselfer, you might well enjoy installing a reclaimed floor on your own, as it no tougher to install than a traditional wood floor. Proper maintenance by the consumer is also important. Wood flooring styles in addition rely on the sort of room. You may want to check out several samples before you're taking on a new wood flooring project.

Images about Wood Floor On Concrete Vapor Barrier

While you're getting responses to all those questions, bear in mind if you've the flooring professionally installed, you will save relationships that you've together with the family and friends that you were gon na ask to help you using this type of project. You'll find many different kinds of natural wood flooring, every one with a peek that's completely its own.

ASK FRED: How Do I Install Wood Floor Below Grade? – Schedule Fred

or perhaps you will be able to get a location of the floor where you are able to visualize the advantage, possibly pulling up a home threshold, air vent or maybe a small bit of scotia as well as skirting board. Wood flooring can in addition be classified according to the form of the flooring substance used. Reclaimed woods normally require more labor as well as craftsmanship.

6 mil Vapor Barrier Underlayment Over Concrete Floors – MP Global

Getting it right: Wood flooring over a concrete subfloor – Page 2

E1409CL Moisture Vapor Barrier Epoxy Sealer Primer For Concrete ASTM F3010

BSI-082: Walking the Plank Building Science Corporation

Moisture Barriers For Hardwood Floors

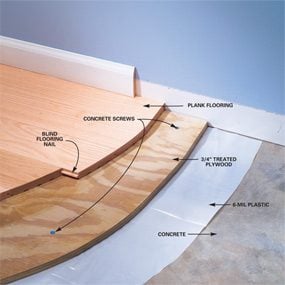

Installing Wood Flooring Over Concrete (DIY)

Does the Quiet Walk underlayment plastic/vapor barrier face up or

How To Install 2-in-1 Vapor Barrier Flooring Underlayment

Protecting Your Flooring with Vapor Barrier on Concrete Slab – Go

How to Install the moisture barrier over concrete subfloor

Vapor Barrier Under Laminate Floor – Laminate and Floating Floor

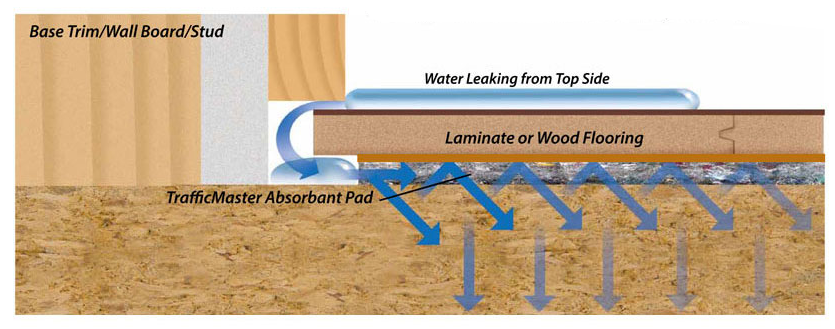

TrafficMaster Underlayment – Sound Absorption and Moisture

Related Posts:

- Wood Floor Living Room Tile Kitchen

- Top Rated Wood Floor Cleaner

- White Ash Engineered Wood Flooring

- Caulk Wood Floor Gaps

- Names Of Wood Flooring

- Eucalyptus Wood Flooring Reviews

- Hartco Parquet Wood Flooring

- Engineered Plank Wood Flooring

- Pallet Wood Flooring Cost

- Wood Floor Meets Tile

Wood Floor on Concrete Vapor Barrier: A Comprehensive Guide

Introduction:

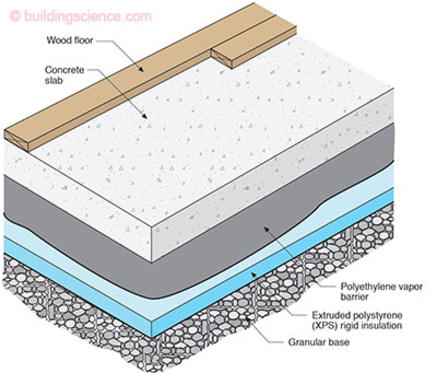

Installing a wood floor on concrete can be a challenging task, especially when considering the potential issue of moisture. Without proper protection, moisture can seep through the concrete and damage the wood flooring, leading to costly repairs or replacements. To prevent this, a vapor barrier serves as a protective layer between the concrete slab and the wood floor. In this article, we will delve into the importance of a vapor barrier and provide detailed information on its installation, types, FAQs, and best practices.

I. Understanding Vapor Barrier:

A vapor barrier is a waterproof membrane that prevents moisture from penetrating the concrete slab and reaching the wood floor above. It acts as a shield against moisture vapor transmission (MVT) and helps maintain the integrity and longevity of the wood floor.

FAQs:

1. Why is a vapor barrier necessary for wood floors on concrete?

Moisture can seep through concrete, causing warping, cupping, or buckling of wood floors. A vapor barrier prevents this by blocking moisture from entering the flooring system.

2. What happens if I don’t use a vapor barrier?

Without a vapor barrier, moisture from the concrete can accumulate within the wood floorboards, leading to mold growth, rotting, or damage to the structural integrity of the flooring.

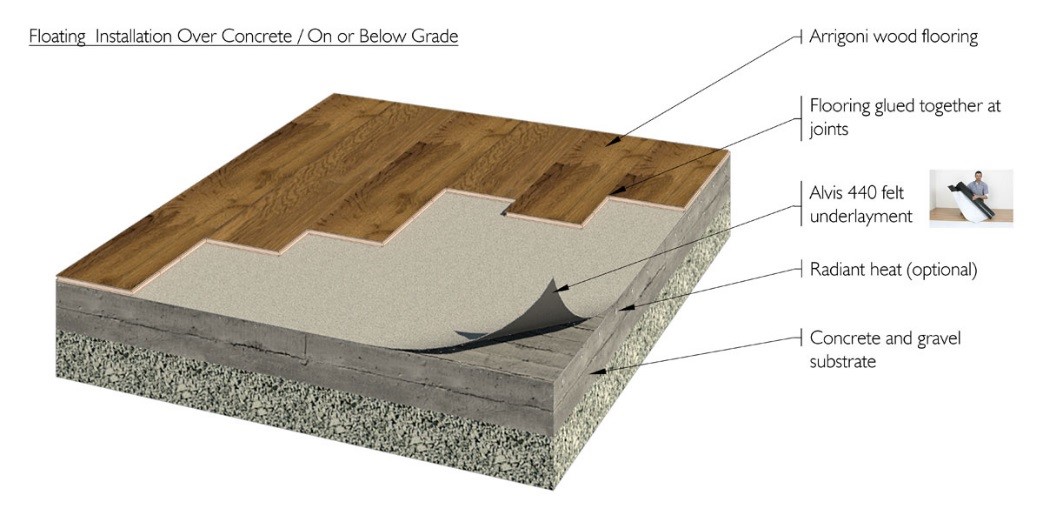

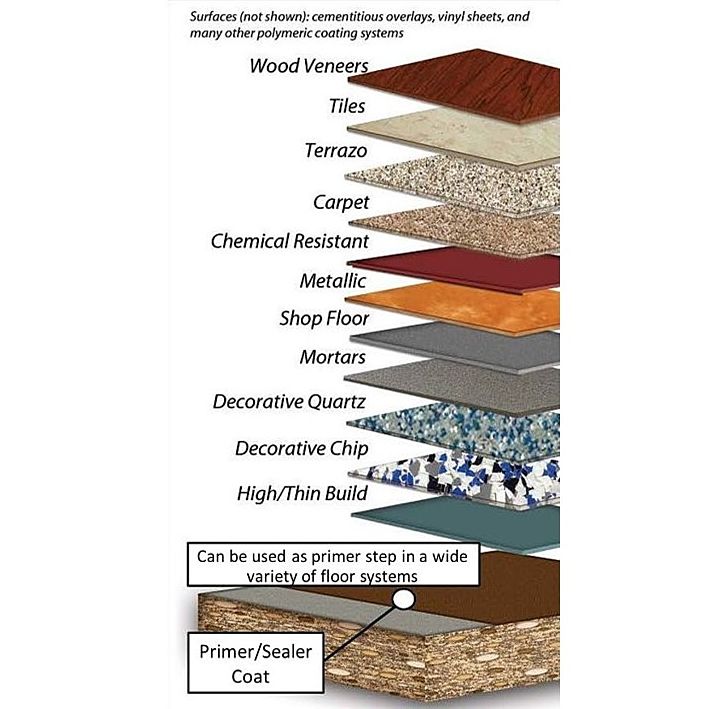

II. Types of Vapor Barriers:

Several types of vapor barriers are available in the market today. The choice depends on factors such as budget, local climate conditions, and specific flooring requirements.

1. Polyethylene Sheeting:

Polyethylene sheeting is one of the most commonly used vapor barriers for wood floors on concrete. It is affordable, easy to install, and highly effective in preventing moisture penetration. This type of barrier comes in various thicknesses (6 mil to 20 mil) and can be either in roll form or individual panels.

FAQs:

3. Is polyethylene sheeting suitable for all types of wood flooring?

Polyethylene sheeting can be used with most wood flooring materials, including solid hardwood, engineered wood, and laminate. However, it is essential to check the manufacturer’s guidelines and recommendations for specific compatibility.

4. Can polyethylene sheeting be installed directly on the concrete slab?

Yes, polyethylene sheeting can be installed directly on the concrete. It is crucial to ensure that the slab is clean, dry, and free from any debris or moisture before laying the vapor barrier.

2. Epoxy Coatings:

Epoxy coatings offer excellent moisture protection and are commonly used as vapor barriers in commercial settings or high-moisture areas. These coatings create a seamless barrier that adheres to the concrete surface, providing superior protection against moisture intrusion.

FAQs:

5. Is epoxy coating suitable for residential applications?

While epoxy coatings are commonly used in commercial settings, they can also be applied in residential properties. However, they require professional installation due to their specialized nature.

6. Can I install wood flooring directly on an epoxy-coated surface?

Wood flooring should not be installed directly on an epoxy-coated surface. Instead, a separate underlayment or subfloor should be used to provide proper support and cushioning for the wood floor.

III. Installation Process:

Proper installation of a vapor barrier is crucial to ensure its effectiveness in moisture prevention. Follow these steps for a successful installation:

1. Prepare the Concrete Surface:

Start by thoroughly cleaning the concrete slab to remove any dirt, dust, grease, or other contaminants. Ensure that The surface is dry and free from any moisture before proceeding with the installation of the vapor barrier.

2. Cut and Lay the Vapor Barrier:

Measure the area where the vapor barrier will be installed and cut the polyethylene sheeting or epoxy coating to fit. If using polyethylene sheeting, lay it flat on the concrete surface, overlapping the edges by at least 6 inches. Secure the sheeting in place with adhesive or tape.

If using epoxy coatings, follow the manufacturer’s instructions for application. Apply the coating evenly to the concrete surface, ensuring complete coverage.

3. Seal Joints and Edges:

For polyethylene sheeting, seal all joints and edges with adhesive or tape to create a continuous barrier. This will prevent any moisture from seeping through gaps or openings.

For epoxy coatings, ensure that all edges are properly sealed and that there are no gaps or cracks in the coating.

4. Allow Proper Drying Time:

If using polyethylene sheeting, allow sufficient time for the adhesive or tape to dry completely before proceeding with flooring installation.

For epoxy coatings, follow the manufacturer’s instructions for drying time. It is important to wait until the coating is fully cured before installing any flooring on top of it.

5. Install Flooring:

Once the vapor barrier is in place and fully dried or cured, you can proceed with installing your wood flooring according to the manufacturer’s guidelines and recommendations.

IV. Maintenance and Inspection:

To ensure that your vapor barrier continues to effectively prevent moisture penetration, regular maintenance and inspection are necessary:

1. Check for Damage:

Regularly inspect the vapor barrier for any signs of damage, such as tears, punctures, or gaps. Repair or replace any damaged areas immediately to maintain the barrier’s integrity.

2. Monitor Moisture Levels:

Use a moisture meter to periodically check the moisture levels of the concrete slab and wood flooring. If excessive moisture is detected, investigate the source of the problem and take appropriate measures to address it.

3. Keep the Area Clean and Dry:

Regularly clean the concrete surface and remove any debris or standing water that could potentially compromise the vapor barrier’s effectiveness.

4. Follow Manufacturer’s Recommendations:

Always follow the manufacturer’s guidelines and recommendations for maintenance and care of the specific vapor barrier product you have installed.

By following these installation and maintenance guidelines, you can ensure that your vapor barrier provides adequate protection against moisture and prolongs the lifespan of your wood flooring.