At the conclusion of this day, the polished concrete floor will look something such as some kind of polished stone, no wonder it's used as a decorative ways in many places. If the concrete floor has been in the past sealed, it is a wise decision to sweep and then mop the area with water and soap, a general cleaning product or a qualified concrete cleaner.

Images about Concrete Floor Construction Techniques

Polished concrete floors are an exceptional method of flooring which are more and more becoming a method of life for many home as well as business people. Polished concrete floors also have quite a few benefits making them an eco-friendly, affordable and practical alternative for apartments and housing. In house and shop settings, concrete floor is also less loud than floorboards of tiles.

Concrete Floor Slab Construction Process – The Constructor

Concrete floors are functional and practical. In the summer season, the concrete floors absorbs moisture from the soil to keep it cooler. In the first place, there's a good sense of affordability in relation to these concrete floors, so much that many people today find them while the best alternative with regards to flooring.

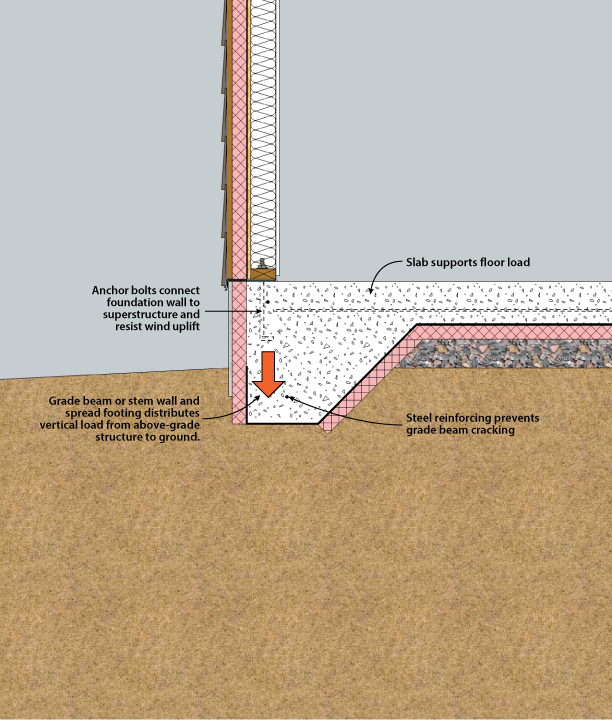

Slab On Grade Foundation Design Slab On Grade Design

Building A Floor A Floor Concrete Slab Foundation

DOE Building Foundations Section 4-1

Concrete Floor Slab Construction Process – The Constructor

Composite floor system Download Scientific Diagram

Concrete Floor Slab Construction Process – The Constructor

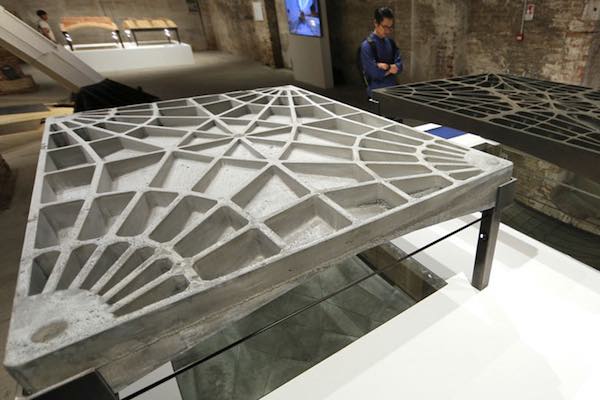

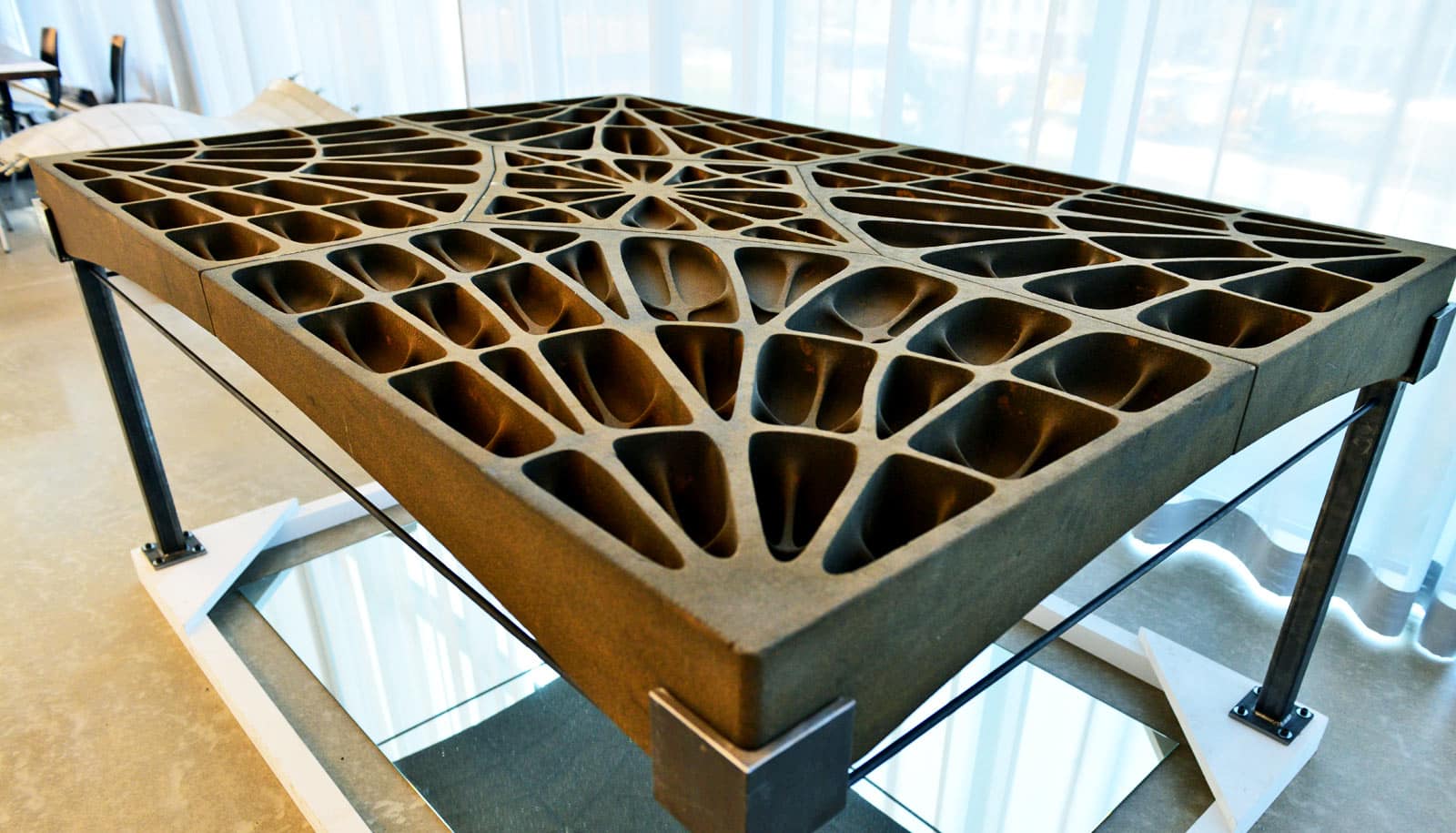

Arched design allows concrete floors to go thinner and lighter

Gothic cathedrals inspire very thin concrete floors – Futurity

Concrete Floor Slab Construction Process – The Constructor

Concrete Finishing – How to Finish Concrete (6 Steps) – Concrete

Floor Construction Methods Attic flooring, Floor installation

The evolution of composite flooring systems: applications, testing

Related Posts:

- Acid Stained Concrete Floors Maintenance

- Are Concrete Floors Slippery

- Electric Concrete Floor Grinder

- Durall Concrete Floor Coatings

- Flooring For A Basement Concrete Floor

- Hawk Concrete Floor Coatings

- How To Install Wood Threshold On Concrete Floor

- How To Seal Concrete Floor In Garage

- Black Mold On Concrete Floor

- Tremix Concrete Flooring Specifications

Concrete Floor Construction Techniques

The construction of a concrete floor is a complex process that requires careful planning and execution. From the preparation of the subfloor to the installation of the concrete itself, there are numerous steps and techniques that must be followed in order to ensure a successful outcome. In this article, we will explore some of the most common concrete floor construction techniques, as well as provide insight into how best to approach each step.

Preparation of Subfloor

Before any concrete can be poured, the subfloor must be prepared to ensure that it is level, stable, and free from any debris or imperfections that could interfere with the curing process. This typically involves laying down an appropriate layer of sand or gravel, depending on the desired type of finish. It is important to make sure that all areas are thoroughly leveled and compacted before proceeding with the next step. Additionally, if there is existing flooring present, it must be removed in order for the concrete to adhere properly.

Installation of Rebar

Once the subfloor has been adequately prepared, it is time to install rebar – steel rods that are inserted into the base material in order to add strength and stability to the concrete. The size and placement of rebar will depend on various factors such as load bearing capacity and anticipated traffic patterns. It is important to ensure that all pieces are correctly aligned before moving on to pouring the concrete.

Pouring Concrete

Now comes the exciting part – pouring the actual concrete! This step is often done by professionals who specialize in this type of work, but it can also be completed by experienced DIYers with proper guidance and safety precautions. Before any concrete is poured, a series of tests should be conducted in order to determine its suitability for use in flooring applications. This includes testing for strength, air content, water absorption rate, etc., as these factors all play an important role in ensuring a high-quality finish. Once all tests are complete and satisfactory results achieved, it is time to start pouring! The concrete should be filled slowly and evenly, while taking care not to create any air pockets or voids in the slab as these can lead to cracking later on.

Finishing Touches

Once all of the concrete has been poured and allowed to cure for at least 24 hours (or according to manufacturer’s instructions), it is time for finishing touches such as smoothing out any rough edges or applying a sealant or coating if desired. This step also involves ensuring that all expansion joints have been installed correctly in order to prevent cracking due to temperature changes or excessive movement. Finally, once everything has been inspected and found satisfactory, it’s time for everyone involved in this project to admire their handiwork!

FAQs

Q: What materials are needed for concrete floor construction?

A: The materials needed for constructing a concrete floor include sand or gravel (for leveling), rebar (for added strength), water (for mixing), cement (for binding), and any desired sealants or coatings (for protection).

Q: How long does it take for a concrete floor to cure?

A: The amount of time needed for a concrete floor to cure will depend on various factors Such as temperature, humidity, and the type of cement used. Generally, it can take anywhere from 24 hours to several days for the concrete to fully cure.

What are the different types of concrete floor construction?

1. Suspended Concrete Slab: A suspended concrete slab is a concrete slab construction in which the slab is suspended off the ground and supported by a structural frame or columns.2. Concrete on Grade (COG): This type of floor construction involves pouring the concrete directly onto the grade in order to create a strong, durable floor.

3. Raised Floor: A raised floor is one that is built above the existing ground level, and it can be either structural or non-structural, depending on its use and design.

4. Precast Concrete Slab: This type of flooring is created from precast concrete slabs that are placed onto a structural frame or foundation and then connected to each other with mortar, grout, or adhesive.

5. Polished Concrete Floors: Polished concrete floors are created by grinding and polishing the surface of a concrete slab to create a glossy finish that is both aesthetically pleasing and highly durable.

What are the benefits of concrete floor construction?

1. Durability: Concrete is one of the most durable flooring materials available, making it ideal for high traffic areas. It also resists wear and tear caused by moisture, chemicals, and extreme temperature changes.2. Cost-Effective: Concrete is one of the most cost-effective flooring materials on the market, making it an attractive choice for budget-conscious homeowners.

3. Versatility: Concrete floors can be customized with a variety of finishes, from polished to stained to textured, allowing you to create a unique look for your home or business.

4. Low Maintenance: Unlike other flooring materials that require regular upkeep, concrete floors are easy to clean and require minimal maintenance over time.

5. Eco-Friendly: Concrete is an environmentally friendly material that does not contain any volatile organic compounds (VOCs). It also helps reduce energy costs by providing thermal mass and absorbing heat throughout the day.