The floors don’t chip off by the corners and there aren’t any scratches. It will become the foundation for a lot of locations. There are a lot of epoxy floor paints which can be purchased from hardware stores but a lot of these simply have some instructions on how to mix it. Epoxy flooring is the process of using layers of epoxy resin during a floor’s surface area, usually up to 2 mm thick.

Images about Cracks In Garage Floor Epoxy

It’s been utilized for years on industrial floors because of its toughness, durability, and resistance to engine oil, grease, and many other chemical compounds that ruin frequent paint. Epoxy may be used to level out problem areas and make sure and also surface. You can put in epoxy flooring of places such as a completed basement, your storage area or perhaps your outdoor deck.

How to Repair Garage Floor Cracks and Pitting All Garage Floors

By applying an epoxy layer on the concrete, the concrete is actually protecting. Marble is stunning, but far more expensive compared to decorated concrete. Epoxy floor coatings, particularly, are widely-used in floor apps. Epoxies are utilized to create sparkling, clean and durable flooring. Also, you mustn’t use epoxy layer if your flooring was used with concrete sealer. Epoxy floors coloring makes areas look much more professional.

Foundation Floor Crack Repair CrackX

The color options are just limited by the company which offers them. Most of these qualities provide longer longevity of surfaces. Applying your own epoxy flooring to a commercial building or a space in the home of yours might be easier than expected. Higher grade epoxy resin is actually utilized to upgrade surfaces, obtain colored effects, protect floors against corrosion, and achieve a water tight effect.

Why do you get cracks in epoxy floors? – A1 Epoxy flooring

Cracks In a Concrete Garage Floor: When Are They Serious – Buyers Ask

CRACK REPAIR EPOXY PUTTY

Garage Floor Epoxy Finish Madison WI Garage Flooring Solutions

How to Repair Concrete Floor Crack Repairs Repair Garage Floor

How to Repair Garage Floor Cracks and Pitting All Garage Floors

Applying epoxy on rough concrete – 3 useful tips

DIY Epoxy Concrete Crack Repair – What I use – How I Repair Concrete

Whatu0027s Cracking? Dealing with Cracks in Epoxy Coatings – Garage

DIY Epoxy Garage Floor Coating Repair – Casper, WY

Armor Tuff Garage Floors: Epoxy Flooring Systems

Related Posts:

- Why Epoxy A Garage Floor

- Epoxy Flooring Baton Rouge

- How Long Before You Can Walk On Epoxy Floor

- How To Epoxy Garage Floor With Flakes

- Imperiale Epoxy Floors

- How To Apply Epoxy Paint To Basement Floor

- Epoxy Flooring Applicators

- Cold Room Epoxy Flooring

- Epoxy Resin Floor Primer

- Rustoleum Epoxy Garage Floor Coating

Introduction

Garage floor epoxy is a popular choice for protecting and beautifying concrete floors. It’s durable, easy to clean, and can last for years. However, like any material, there are certain issues that can arise with garage floor epoxy. One of the most common is the presence of cracks in the epoxy. In this article, we’ll discuss the causes of cracked epoxy, how to prevent them, and how to repair them.

Causes of Cracks in Garage Floor Epoxy

There are several potential causes of cracks in garage floor epoxy. The most common is poor installation technique. If the epoxy is not properly mixed or applied, it can cause weak spots that become vulnerable to cracking. Other causes include extreme temperature changes, such as when the temperature drops abruptly during a cold snap or rises quickly during a heat wave. In addition, heavy weight on the surface of the epoxy can cause it to crack, as can exposure to chemicals or solvents. Finally, simply age can cause the epoxy to become brittle and crack over time.

How To Prevent Cracks in Garage Floor Epoxy

The best way to prevent cracks in garage floor epoxy is to ensure that it’s installed correctly in the first place. This means mixing and applying it according to manufacturer instructions and inspecting it regularly for signs of damage or wear. It’s also important to keep the temperature inside your garage consistent by installing insulation or fans if necessary. Finally, try to avoid putting too much weight on the epoxy surface and limit exposure to chemicals and solvents whenever possible.

How To Repair Cracks In Garage Floor Epoxy

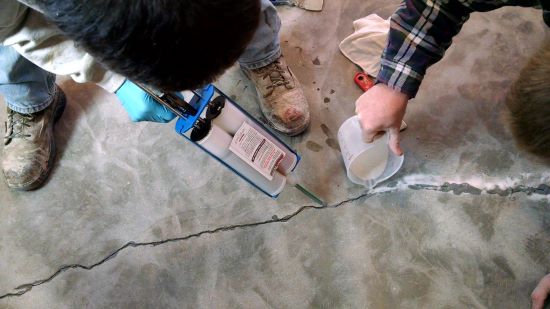

If you already have cracks in your garage floor epoxy, don’t worry – they can be repaired fairly easily with a few simple steps. First, you’ll need to prepare the surface by cleaning it thoroughly with soap and water then allowing it to dry completely before proceeding. Once the surface is clean and dry, you’ll need to fill in any cracks with an appropriate patching material such as concrete patch or filler specifically designed for use with epoxy floors. Once your patching material is dry and hardens, you’ll need to sand it smooth before applying a new layer of clear coat or sealant over top.

FAQs About Cracks In Garage Floor Epoxy

Q: What causes cracks in garage floor epoxy?

A: The most common cause of cracks in garage floor epoxy is poor installation technique. Other potential causes include extreme temperature changes, heavy weight on the surface of the epoxy, exposure to chemicals or solvents, and simply age over time causing it to become brittle and crack.

Q: How do I prevent cracks in my garage floor epoxy?

A: The best way to prevent cracks in garage floor epoxy is by ensuring that it’s installed correctly in the first place according to manufacturer instructions. It’s also important to keep the temperature inside your garage consistent by installing insulation or fans if necessary as well as avoiding putting too much weight on the surface and limiting exposure to chemicals or solvents whenever possible.

Q: How do I repair existing cracks in my garage floor epoxy?

A: If you already have existing cracks in your garage floor epoxy, You can repair them fairly easily. First, you’ll need to prepare the surface by cleaning it thoroughly with soap and water then allowing it to dry completely before proceeding. Once the surface is clean and dry, you’ll need to fill in any cracks with an appropriate patching material such as concrete patch or filler specifically designed for use with epoxy floors. Once your patching material is dry and hardens, you’ll need to sand it smooth before applying a new layer of clear coat or sealant over top.

What causes cracks in garage floor epoxy?

Cracks in epoxy garage floors can be caused by many different things, including: poor surface preparation, improper mixing of the epoxy, incorrect application of the epoxy, poor ventilation in the area, improper curing of the epoxy, and temperature fluctuations.

What is the best way to repair cracks in a garage floor epoxy?

The best way to repair cracks in a garage floor epoxy is to use a two-part epoxy repair kit. These kits contain an adhesive and a filler that are mixed together and then applied to the cracks. The adhesive helps to bond the filler to the damaged area, while the filler fills in voids and helps to seal the crack from moisture. After applying the mixture, it should be allowed to cure for at least 24 hours before any heavy traffic is allowed on the repaired area.

What type of epoxy should be used to repair cracks in a garage floor?

The best type of epoxy to use for repairing cracks in a garage floor is a two-component, solvent-based epoxy. This type of epoxy is both flexible and strong, making it ideal for sealing cracks, filling small holes, and creating a waterproof barrier.