This particular option revolves around the facts that epoxy flooring is highly durable, involves minimum maintenance and is eco friendly. This would lessen some wastage and save you cash. The professionals understand every single aspect of the surfacing and they could make use of the latest technology for implementing the epoxy paint over the floors of yours.

Images about Epoxy Flooring Applicators

Epoxy floors coating is a flooring surface area made up of multiple tiers of epoxy put on to the floor to a degree of only 2 millimeters. Epoxy seamless is actually a great idea for manufacturing workshop, garage and also for kid's bedroom floors to cover dull, gray concrete and present you with protected, appealing, not difficult to clean surfaces.

The Importance of Hiring Experienced Epoxy Flooring Contractors

The color choices are only constrained by the business which offers them. All of these traits give longer longevity of surfaces. Applying your very own epoxy flooring to a commercial building or perhaps an area in the house of yours could be easier than expected. High grade epoxy resin is actually utilized to upgrade surfaces, obtain colored effects, protect floors against corrosion, and attain a water tight effect.

Epoxy Equipment: What is needed to apply an epoxy floor

Its reliability and longevity can endure damages and still keep the appearance of its. The looks of flooring more improves with amazing possibilities of color combinations. They are tough, enduring, and comes in many colors. The chemical layer not just makes the floor look very good but also raises the long life of the floors in turn reducing the maintenance cost.

Epoxy Flooring Contractors

Epoxy Flooring Installers u2014 Epoxy Flooring Contractors, Terrazzo

Epoxy Flooring Contractors Concrete Epoxy Contractors Riverside

What Is Epoxy Flooring Application Process of Epoxy Flooring

Top Services to Look for from a Contractor When Searchingu2026 Kaloutas

Epoxy Flooring Contractors in Palmdale, CA – Epoxy.LA

Resin Flooring Contractors: How to Find One

Epoxy Flooring Contractors in NJ Alpine Painting

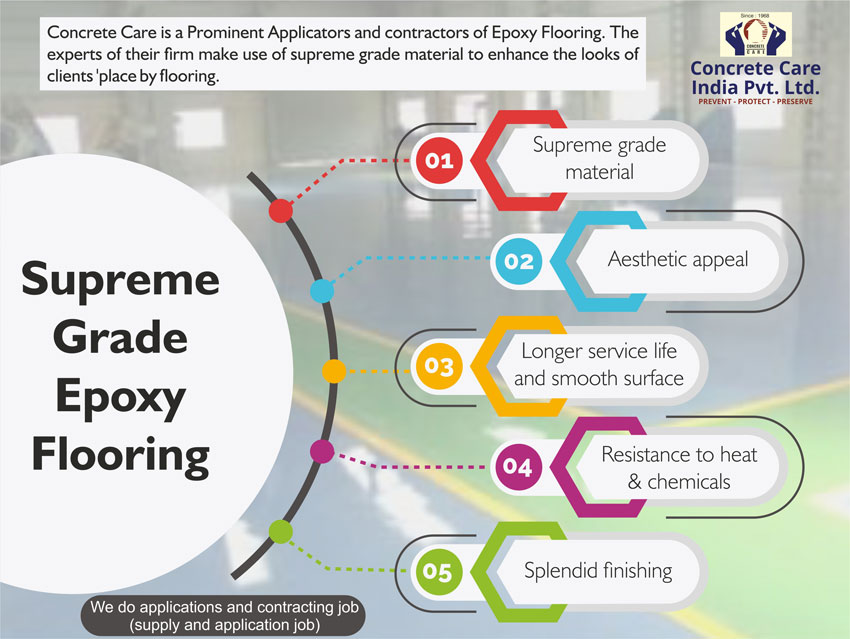

Advantages of Epoxy Flooring application- Concrete Care

Surface Preparation in Epoxy Flooring: Explaining the different

Nashville Epoxy Flooring Contractors: 5 Reasons to Work with Us

Related Posts:

- Remove Epoxy Coating From Concrete Floor

- High Build Epoxy Floor Coating

- Benefits Of Epoxy Garage Floor

- Epoxy Polyurethane Flooring Systems

- Epoxy Paint Floor Garage

- How To Clean Epoxy Coated Garage Floors

- Epoxy Garage Floor Coating On Wood

- Black Gloss Epoxy Flooring

- Epoxy Floor Paint Rustoleum

- Best Epoxy Floor Paint For Garage

Epoxy Flooring Applicators: Professional Installation for Lasting Durability

If you’re looking for a durable, attractive floor covering that can stand up to heavy traffic and last for decades, epoxy flooring is a fantastic choice. With its rich colors, glossy finish, and superior durability, epoxy flooring offers the perfect combination of beauty and strength. However, epoxy flooring installation requires special skills and expertise. That’s why it’s so important to choose experienced epoxy flooring applicators who can ensure professional results—and lasting durability.

What Is Epoxy Flooring?

Epoxy floor coatings are made from a combination of resin and hardener that form a plastic-like material when mixed together. When applied to a concrete surface, this material forms a strong bond with the concrete, creating an impenetrable barrier that resists staining, chipping, and other damage. In addition to its strength and durability, epoxy floor coatings also offer excellent color retention and scratch resistance, making them ideal for high-traffic areas such as garages, workshops, warehouses, factories, and commercial buildings.

Why Choose Professional Epoxy Flooring Applicators?

While DIY epoxy flooring kits are available in many home improvement stores, these kits are not designed to provide the same level of performance as professionally installed systems. Professionally installed epoxy floor systems are more durable, longer lasting, and less likely to crack or chip than DIY systems. Professional installation also ensures that your new epoxy floor will look beautiful for years to come.

In addition to providing superior performance and longevity, professional epoxy applicators also have the experience and expertise to properly prepare the surface before installation. Proper preparation is essential in order to ensure maximum adhesion between the epoxy coating and the concrete substrate. If the surface is not properly prepared prior to application of the coating, it may fail prematurely or not adhere properly. Professional applicators know exactly how to prepare a surface for optimal results, leading to a beautiful finish that will last for decades.

What Should You Look for in an Epoxy Flooring Applicator?

When selecting an epoxy applicator for your project, it’s important to choose one with experience in applying epoxy coatings on concrete surfaces. It’s also important to select an applicator who is knowledgeable about different types of epoxies and their various applications. You should also make sure that the applicator you select is familiar with local building codes and regulations related to epoxy coatings and has the proper licenses and insurance coverage in place. Finally, it’s wise to ask for references from previous customers who have used the same applicator in order to ensure you get quality results on your project.

FAQs about Epoxy Flooring Applicators

Q: What are the benefits of hiring a professional epoxy flooring applicator?

A: Hiring a professional epoxy flooring applicator provides several key benefits over do-it-yourself kits or unqualified installers. Professional installers have experience in applying epoxies on concrete surfaces; they understand how different types of epoxies perform; they know local building codes; they are insured against any Potential damages; and they provide quality results that will last for years.

What tools are needed to apply epoxy flooring?

Tools needed to apply epoxy flooring include a concrete grinder, sander, trowel, notched squeegee, paint roller, and plastic putty knife. You will also need protective gear such as gloves, goggles, and respirator.What is the best way to prepare a concrete floor for epoxy coating?

1. Clean the surface: Sweep and vacuum the floor to remove any dirt and debris. Scrub the surface with a degreaser to remove any oil or grease stains. Rinse the floor with clean water, then allow it to dry completely.2. Repair any damage: Patch any cracks or holes using a concrete patching compound. Allow it to dry completely before proceeding.

3. Sand the surface: Use a sander and 120-grit sandpaper to sand down the entire concrete surface. This will create a good bonding surface for the epoxy coating.

4. Clean up the dust: Vacuum up all of the dust that has been created by sanding the floor, then use a damp cloth to wipe away any remaining dust particles. Allow the floor to dry completely before applying any epoxy coating.