These can guard garage floor from the impact of products stored. Tire tracks as well as other aesthetic damages are able to happen when you do not allow the flooring of yours ample time to dry out. Many garage floors are easy enough for the normal homeowner to set up themselves and so , if you are up to the task, you ought to be ready to install any of these floors.

Images about Garage Floor Alternatives To Concrete

Garages these days have much larger utilities than mere automobile parking places. From time to time there are areas that need to be filled before putting on floor mats in order to ensure a smooth and professional appearance. Adaptable floor surfaces are considerably more comfy to stand on compared to a ceramic device or perhaps simple cement. It is well worth the effort and hard work to do it right.

Top 10 u2013 Alternatives To Concrete Garage Floors u2013 Houshia

If either of these 2 uses is common to you then maybe you have considered garage flooring. The diamond texture is done for garages used largely for storing cars. Thus, if you need the garage of yours to look and feel great, the first thing to do is install a garage floor coating. These water leaks can in addition result in conditions that are unsafe as they create the floor very slippery.

Best Garage Floor Coating of 2022 – This Old House

/cdn.vox-cdn.com/uploads/chorus_asset/file/22308892/1120_FEA_Idea_House_Fairfield_Farmhouse_08142020NR_0078_v3.jpg)

19 Concrete Alternatives That Save Money u0026 The Planet – Worst Room

Is There an Eco-Friendly Alternative to Epoxy Floor Coating?

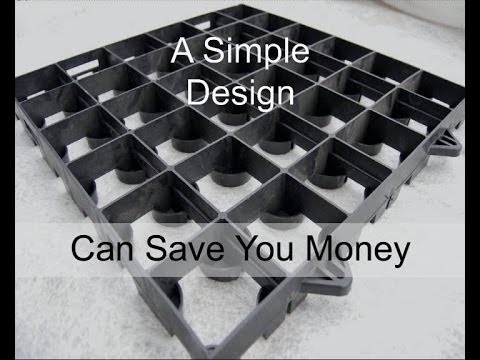

Ecobase Foundation Install Video – The Intelligent, Ecological Alternative To Concrete.

Best Options To Cover A Dirt Floor

Gorgeous Flooring Alternatives for Your Garage – Flores

Garage Floor Ideas – 8 Easy and Affordable Options – Bob Vila

The Facts about Polished Concrete Garage Floors All Garage Floors

Hello Garage Before and After Photos

Paint is a Cheap Alternative to Enhance the Looks of your Garage

Concrete Coating Professionals in Lehi, Utah Lifetime Epoxy Utah

Best Alternative For Concrete Garage Floor – Workshopedia

Related Posts:

- Garage Floor Paint Designs

- Garage Floor Acrylic Sealer

- Peel And Stick Garage Flooring

- Tuck Under Garage Floor Plans

- Craftsman Garage Floor Tiles

- Racedeck Garage Flooring Reviews

- Garage Floor Coating Service

- Rustoleum Garage Floor Epoxy Paint

- Rubber Garage Floor Mats For Cars

- Garage Floor Vinyl Tile

Garage Floor Alternatives To Concrete

When it comes to garage flooring, concrete has been the go-to option for many homeowners. However, there are several alternative materials that can be used to create a durable and attractive garage floor. In this article, we will explore some of the best alternatives to concrete and discuss their benefits, drawbacks, and installation processes.

1. Epoxy Flooring

Epoxy flooring is a popular choice for homeowners looking to upgrade their garage floors. This type of flooring is created by applying multiple layers of epoxy resin to the concrete surface. The result is a glossy, smooth, and highly durable floor that is resistant to stains, chemicals, and impacts.

One of the main advantages of epoxy flooring is its versatility. It comes in a wide range of colors and finishes, allowing homeowners to customize their garage floors according to their preferences. Additionally, epoxy coatings can be applied with slip-resistant additives to improve safety.

Installation Process: Installing epoxy flooring typically involves several steps. First, the concrete surface needs to be thoroughly cleaned and any cracks or imperfections repaired. Then, the epoxy resin is mixed according to the manufacturer’s instructions and applied evenly over the entire floor using a roller or squeegee. After the first coat has dried, additional layers may be applied for added durability.

FAQs:

Q: How long does an epoxy garage floor last?

A: When properly installed and maintained, an epoxy garage floor can last between 10-20 years or even longer.

Q: Can I install epoxy flooring myself?

A: While DIY kits are available, professional installation is recommended for optimal results as it requires proper surface preparation and application techniques.

2. Rubber Flooring

Rubber flooring offers excellent durability and resilience, making it an ideal choice for high-traffic areas such as garages. It provides a cushioning effect that reduces fatigue on joints while also acting as a sound barrier.

One of the notable benefits of rubber flooring is its easy installation. It often comes in interlocking tiles or rolls that can be easily fitted together without the need for adhesives. Rubber flooring is also available in various colors and patterns, allowing homeowners to create a unique and visually appealing garage floor.

Another advantage of rubber flooring is its resistance to moisture, making it suitable for areas prone to spills or dampness. It is also easy to clean and maintain, requiring only regular sweeping or mopping.

Installation Process: Installing rubber flooring is a relatively simple process. First, the concrete floor needs to be thoroughly cleaned and dried. Then, the rubber tiles or rolls can be laid out on the surface, ensuring a proper fit and alignment. For interlocking tiles, they can be locked together using a rubber mallet. Adhesive may be required in some cases to ensure stability.

FAQs:

Q: Is rubber flooring suitable for heavy vehicles?

A: Yes, rubber flooring is highly durable and can withstand the weight of heavy vehicles such as cars or trucks.

Q: Can I install rubber flooring over existing concrete?

A: Yes, rubber flooring can be installed directly over concrete as long as the surface is clean and level.

3. Polyurea Coatings

Polyurea coatings are gaining popularity as an alternative to traditional concrete garage floors. This advanced coating technology offers exceptional durability, chemical resistance, and faster installation times compared to epoxy coatings.

One of the key advantages of polyurea coatings is their quick curing time. Unlike epoxy coatings that require several days to fully cure, polyurea coatings Typically cure within a few hours. This means that homeowners can use their garage floor much sooner after installation.

Polyurea coatings also offer superior resistance to chemicals, including oils, fuels, and solvents. This makes them an excellent choice for garages where spills and leaks are common. Additionally, these coatings are highly durable and can withstand heavy traffic and impact without chipping or cracking.

Installation Process: The installation process for polyurea coatings involves several steps. First, the concrete floor needs to be cleaned and any cracks or imperfections should be repaired. Then, a primer is applied to ensure proper adhesion. Next, the polyurea coating is mixed and applied using a roller or spray equipment. The coating is then left to cure for a specified amount of time before it can be used.

FAQs:

Q: How long does it take for polyurea coatings to cure?

A: Polyurea coatings typically cure within a few hours, allowing homeowners to use their garage floor sooner compared to epoxy coatings.

Q: Can polyurea coatings be applied over existing epoxy coatings?

A: Yes, polyurea coatings can be applied over existing epoxy coatings as long as the surface is properly prepared and in good condition.