Epoxy flooring is often produced by a contractor if it's a business task, but there are many diverse sets out there that homeowners can acquire to epoxy their garages and basements. With this particular quality hence you've an alternative of using a durable flooring resistant to water, chemical substances and stains and also one which infuses a taste of elegance.

Images about Polyaspartic Garage Floor Coating Vs Epoxy

Epoxy flooring provides a total strategy to these problems. Epoxy is made up of hardeners and also resins. It's high resistance to abrasion and chemicals for instance alkalis, gasoline, greases, thawing salts, and solvents. For ideal epoxy drying, air temperature should be between 60 and ninety degrees with the minimum concrete temperature of 55 degrees F. A blank concrete floor isn't so appealing or even professional looking.

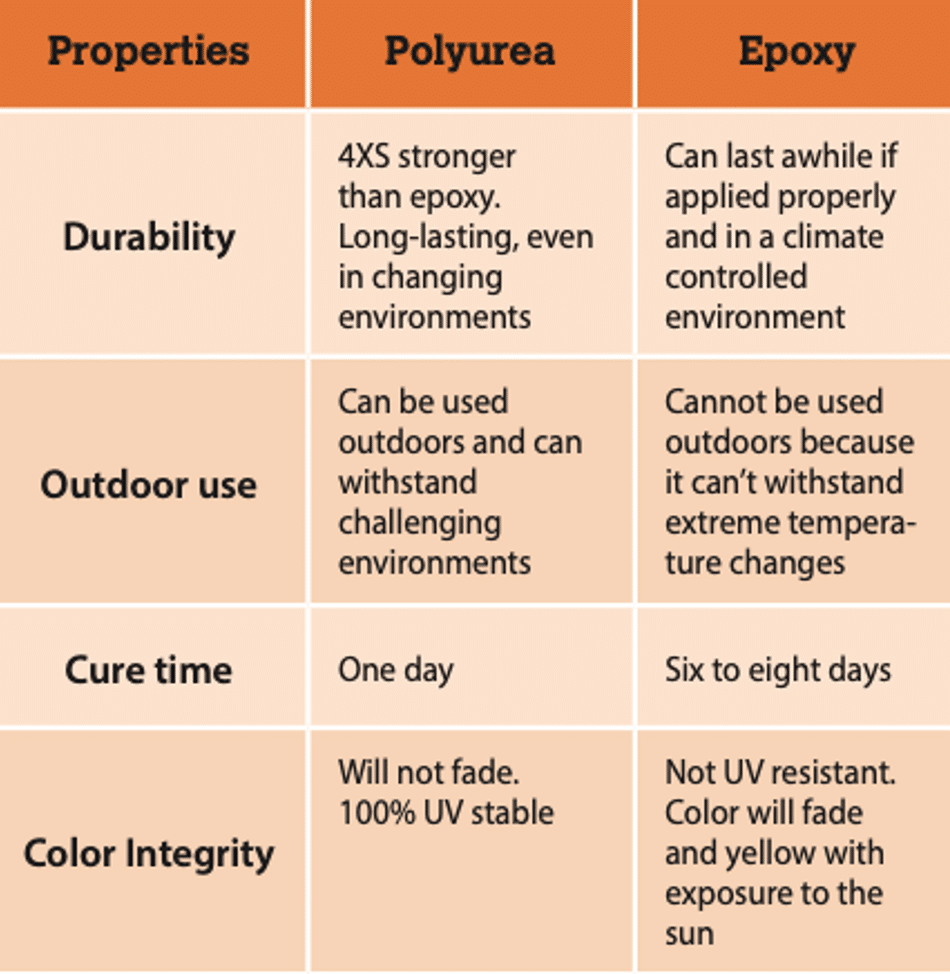

Galaxyu0027s Polyurea/Polyaspartic Coatings vs Epoxy Coatings – Galaxy

The epoxy floors coatings tend to be applied over concrete floors to provide best binding benefits and aesthetically appealing surfaces. Epoxy floors are able to stand up to high pressure and weight. The most widely used sort of epoxy floors for the home is actually the water used version as it likely the simplest of them to make use of as it's made up both of the primer or topcoat and is absolutely perfect for using in garage areas.

EPOXY or POLYASPARTIC? A Step by step guide for an epoxy u0026 paint chip garage floor.

To have an epoxy layer applied to the floors of theirs a household can purchase a package from home improvement stores. Epoxy flooring is an extremely long-lasting flooring surface area for many shops and garages. They can be applied on all varieties of surfaces such as concrete as well as other floor components and sometimes, even on broken floors.

Polyaspartic Vs. Epoxy Garage Floor Coating Best Materials

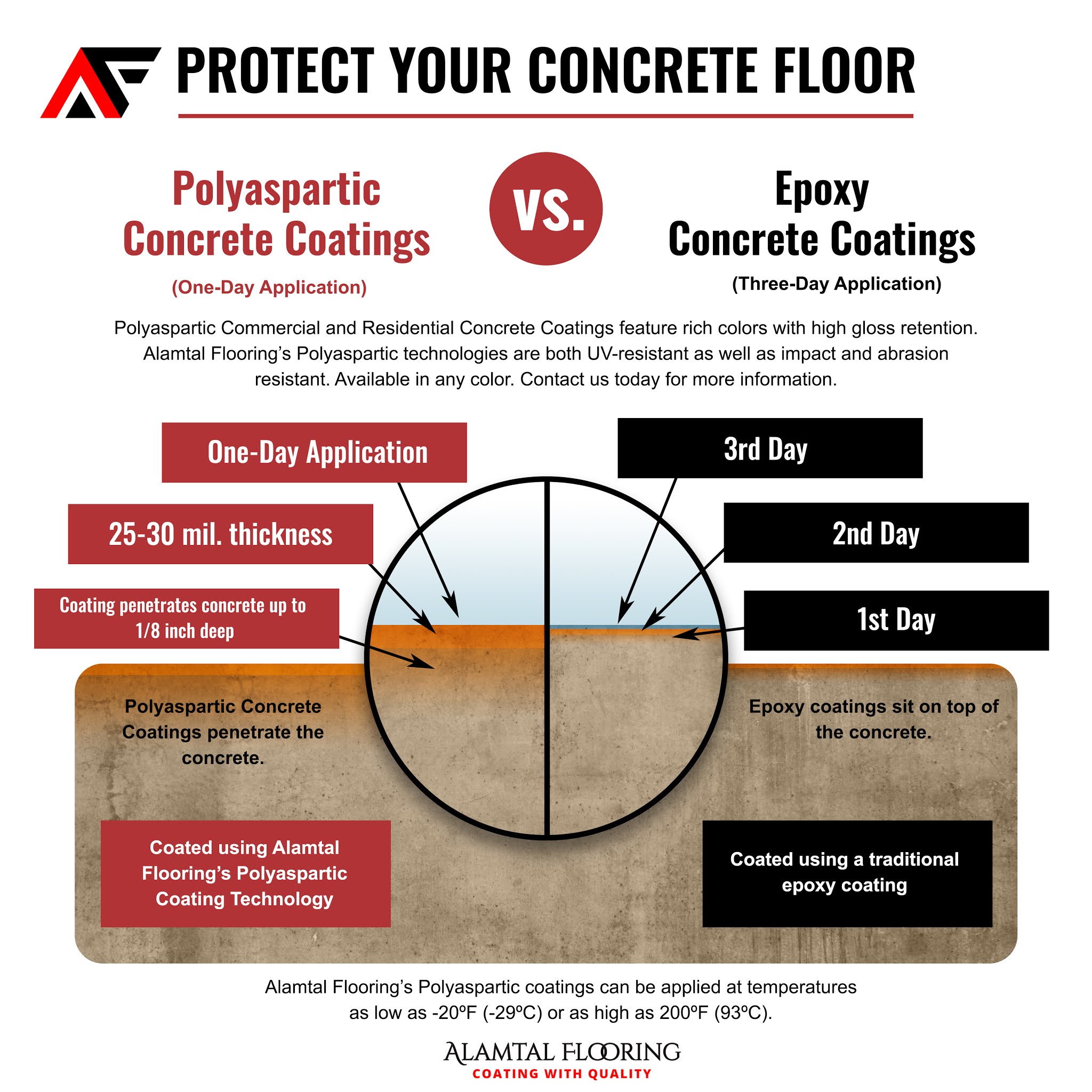

EPOXY VS. POLYASPARTIC FLOOR COATING u2013 Alamtal Flooring

Epoxy, Polyurea or Polyaspartic : Which is the BEST garage floor coating?

Polyaspartic vs. Epoxy Garage Floor Coating – Flooring Inc

Polyaspartic vs. Epoxy Floor Coatings: Which is Better?

Homeowners Garage Floor Epoxy or Polyaspartic Coating Guide

Peoria Epoxy V Polyaspartic Floor Coats Barefoot Surfaces

Polyaspartic Vs Epoxy Garage Flooring What Is The Difference?

Comparing Polyaspartic and Epoxy Garage Floor Coatings News and

Best Garage Floor Coatings for Durability u0026 Protection

Polyaspartic vs. Epoxy Garage Floor Coating – Flooring Inc

Related Posts:

- 1 Part Epoxy Concrete & Garage Floor Paint

- DIY Epoxy Flooring Systems

- Green Epoxy Floor

- Broadcast Epoxy Flooring

- Decorative Epoxy Floor Finishes

- Marble Epoxy Garage Floor

- Do It Yourself Epoxy Basement Floor

- Concrete Terrazzo Epoxy Floor Coatings

- Epoxy Vs Urethane Garage Floor Coating

- Nippon Epoxy Floor Paint

Polyaspartic Garage Floor Coating Vs Epoxy: Understanding the Differences

Garage floors are exposed to a lot of wear and tear. This is why it is important to use the right kind of coating on your garage floor. Two of the most popular choices are polyaspartic and epoxy coatings. While they both provide protection for your garage floor, they have distinct differences that need to be considered before making a decision.

Advantages of Polyaspartic Garage Floor Coating

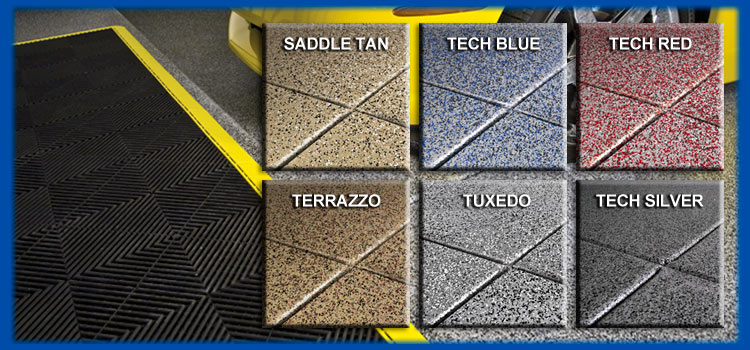

Polyaspartic garage floor coating is an aliphatic polyurea coating that offers superior protection against dirt, oil, grease, and other contaminants. It is also highly resistant to UV rays and other harsh weather conditions. Additionally, it comes in a variety of colors and designs, making it easier to customize the look of your garage floor.

One major advantage of polyaspartic garage floor coating is that it dries quickly. This makes it ideal for busy households or people who don’t have much time to invest in their garage floors. The coating can be applied in just one coat and can be ready to walk on within hours after application. This makes it much faster than epoxy coatings which take days to cure and can be walked on only after several days.

Another advantage of polyaspartic coating is its flexibility. It is able to expand and contract with the changing temperature, which helps prevent cracking or peeling over time. Additionally, it forms a strong bond with the concrete surface, making it highly durable and long-lasting even when exposed to heavy traffic or extreme temperatures.

Advantages of Epoxy Garage Floor Coating

Epoxy is another type of garage floor coating that has been used for years due to its durability and resistance to oil, grease, and other contaminants. Epoxy comes in a variety of colors and designs, making it easy to customize the look of your garage floor according to your needs or preferences.

The major advantage of epoxy coatings is its strength and durability compared to other types of coatings. It forms a strong bond with the concrete surface which makes it highly resistant to scratches, chips, and abrasions from heavy traffic or equipment. Additionally, epoxy coatings are also resistant to chemical spills such as motor oil or gasoline which makes them an excellent choice for garages where such liquids may be stored or used regularly.

Epoxy coatings are also easy to clean and maintain due to their smooth glossy finish which does not allow dirt or dust particles to settle into its surface easily. Additionally, epoxy coatings are highly resistant to UV rays which helps protect them from fading over time due to prolonged exposure to sunlight.

FAQs about Polyaspartic Garage Floor Coating Vs Epoxy

Q: What is the difference between polyaspartic and epoxy garage floor coatings?

A: The main difference between polyaspartic and epoxy garage floor coatings is their drying times; polyaspartic dries quickly while epoxy takes longer time for curing before you can walk on it again. Additionally, polyaspartic offers more flexibility which helps prevent cracking or peeling over time while epoxy provides superior resistance against scratches, chips, abrasions from heavy traffic Or equipment.

What are the benefits of using polyaspartic garage floor coating instead of epoxy?

1. Faster installation and curing time: Polyaspartic garage floor coatings are typically installed in one to two days, compared to the three or four days typically required for epoxy coatings.2. Higher resistance to chemicals and staining: Polyaspartic coatings are highly resistant to chemicals, stains, and oil, making them a great choice for garages that may be exposed to spills from the car or other sources.

3. Better UV protection: Polyaspartic coatings are more resistant to fading and discoloration due to UV exposure than epoxy coatings, meaning that your garage floor will look better and last longer.

4. Higher gloss finish: Polyaspartic coatings provide a higher gloss finish, giving your garage floor a more attractive appearance than an epoxy coating.

5. Greater durability: Polyaspartic coatings are more durable than epoxy coatings, meaning that they can stand up to heavier foot traffic and frequent cleaning without showing signs of wear and tear.

What is the difference between polyaspartic and epoxy garage floor coatings?

Polyaspartic garage floor coatings are much faster to apply than epoxy coatings and provide superior gloss and color retention. Polyaspartic coatings also cure in a fraction of the time and provide superior chemical and scratch resistance. In addition, polyaspartic coatings are more heat resistant than epoxy coatings, making them a better choice for garages with high foot traffic or vehicles that use hot exhaust.What are the benefits of polyaspartic garage floor coatings?

1. Durability: Polyaspartic garage floor coatings are extremely durable and can last up to 10 years without requiring maintenance.2. Speed: The curing time for polyaspartic coatings is much shorter than that of other floor coatings, meaning the entire installation process can be completed in just a few hours.

3. Strength: Polyaspartic garage floor coatings are very strong and resistant to wear, scratches, and abrasions, making them ideal for high-traffic areas.

4. Cost: Polyaspartic garage floor coatings are more cost-effective than traditional epoxy coatings, making them a great choice for budget-conscious homeowners.

5. Versatility: Polyaspartic garage floor coatings can be applied to a variety of surfaces including concrete, wood, and metal, making them a versatile coating option.