Bear in mind concrete flooring is usually discussed with a number of substances including epoxy, an attractive durable finish which can be used at any place in the home. Concrete office flooring is a dark green choice that frequently outlasts other floor varieties like carpet, tile, wood, and linoleum.

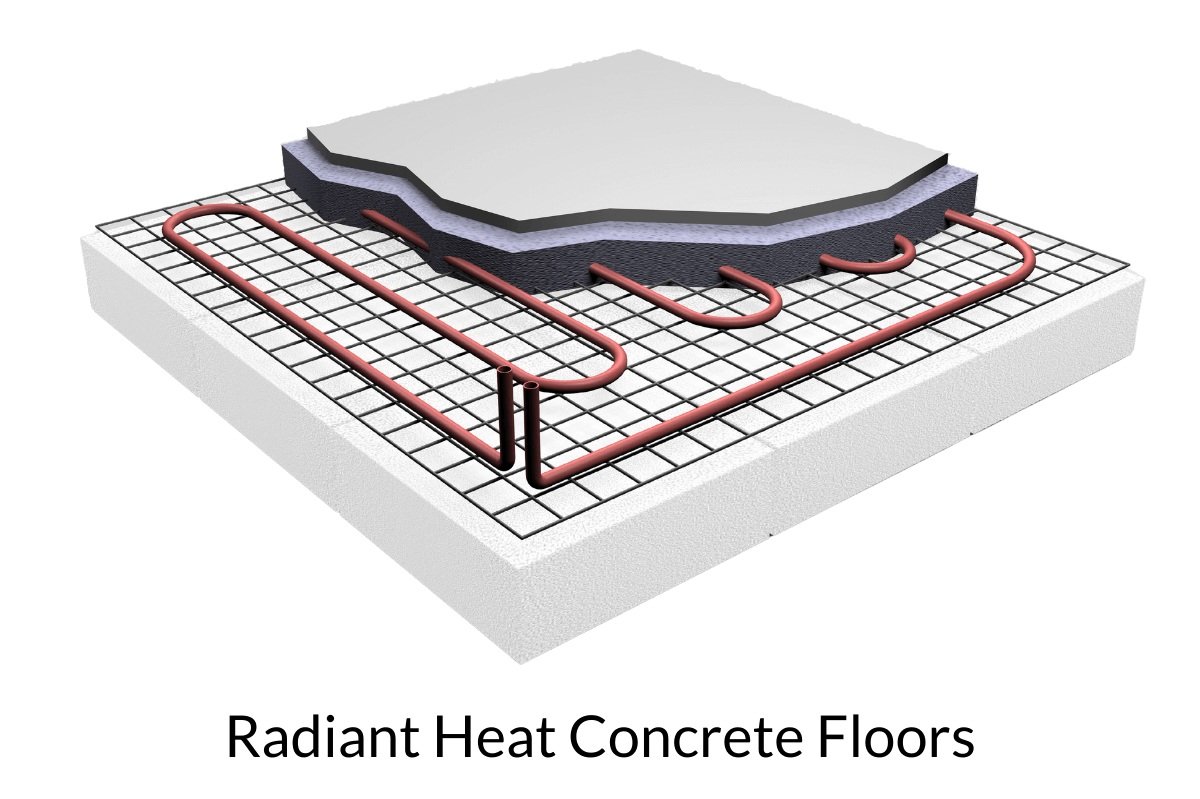

Images about Radiant Concrete Floor Heating Installation

The polished concrete floor look is done with matte to huge gloss finishes. Concrete flooring has some excellent attributes like it is fire-burn resistant, has excellent resistance to hazardous chemicals, is basic and its thickness patterning provides extended life wear ability.

Concrete Floor Heating – Learn the truth about Radiant Heat

You'll have a convenient subfloor for epoxy, tile, carpeting, or maybe whatever surface you desire if you ever get tired of the bare concrete flooring look. This undoubtedly becomes the reason why the need for polished concrete floors today has skyrocketed, along with folks are opting for it as an economical and innovative choice outdoor & indoor.

Hydronic Radiant Heating – Concrete Application – YouTube

Concrete

Radiant Heating In Polished Concrete Floors u2014 Craftsman Concrete

Janes Radiant – Install Radiant Floor Heating Yourself

Solar Radiant Heated Floor Kit – Slab on Grade for LEED, Passive

Installing Radiant Pex Tubing In Concrete Slab Pole Barn House Ep 8

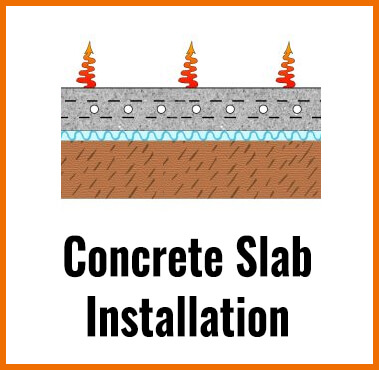

The Slab on Grade Installation DIY Radiant Floor Heating

Radiant Floor Heating- Tubing Installation Methods – Radiantec

The Slab on Grade Installation DIY Radiant Floor Heating

Electric Under Slab Floor Heating u2013 250 sq. ft., 240 V ThermoSoft

Radiant Heating Systems, Residential, Commercial, Greenhouse

Radiant Floor Heating Green Building Winsome Construction

Related Posts:

- How To Shine Up Concrete Floors

- Commercial Kitchen Concrete Floor Sealer

- Indoor Concrete Flooring Ideas

- Advantages Of Precast Concrete Floors

- Building Concrete Floor Slab

- Concrete Floor Problems

- Industrial Concrete Floor Grinders

- Concrete Floor Cost Estimator

- Stained Concrete Floors In Basement

- Tremix Concrete Flooring Specifications

Radiant Concrete Floor Heating Installation: A Comprehensive Guide

Introduction:

Radiant concrete floor heating is an increasingly popular method of heating homes and buildings. This innovative system provides comfortable and efficient heating by utilizing the thermal mass of concrete floors. In this article, we will delve into the details of radiant concrete floor heating installation, exploring its benefits, installation process, related FAQs, and more.

Benefits of Radiant Concrete Floor Heating:

1. Energy Efficiency: Radiant concrete floor heating systems are highly energy-efficient compared to traditional heating methods. By utilizing the thermal mass of the concrete floors, these systems evenly distribute heat throughout the space, reducing energy consumption.

2. Comfortable Heating: Unlike forced-air systems that circulate hot air through vents, radiant floor heating provides gentle and even heat from the ground up. This creates a more comfortable living environment with fewer temperature fluctuations and drafts.

3. Design Freedom: Installing radiant concrete floor heating gives homeowners greater design freedom as it eliminates the need for bulky radiators or ductwork. This allows for more flexibility in furniture placement and interior design choices.

4. Health Benefits: Unlike forced-air systems that can circulate dust particles and allergens, radiant floor heating does not disturb the air or create drafts. This makes it an ideal choice for individuals with allergies or respiratory conditions.

Installation Process:

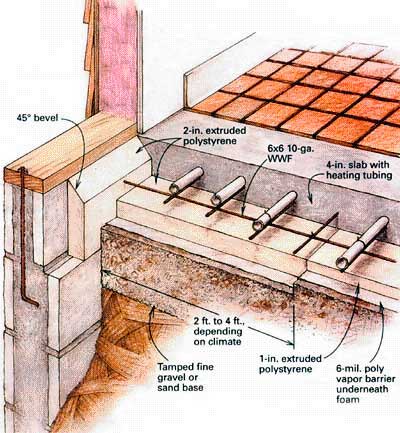

1. Designing the System: The first step in installing radiant concrete floor heating is to design the system according to the specific requirements of the space. Factors such as room size, insulation levels, and desired heat output need to be considered during this stage.

2. Preparing the Subfloor: Before installing the radiant tubing, it is essential to prepare the subfloor properly. The subfloor should be clean, level, and free from any debris or protrusions that may damage the tubing.

3. Installing Insulation: Insulation plays a crucial role in maximizing energy efficiency. It helps prevent heat loss to the ground and directs the heat upwards. Insulation boards or reflective barriers are commonly used for this purpose.

4. Laying the Tubing: The next step involves laying the radiant tubing over the insulation. This tubing is typically made of cross-linked polyethylene (PEX) and comes in pre-formed mats or loops. It is essential to follow the manufacturer’s guidelines for spacing and layout to ensure optimum heat distribution.

5. Connecting the Manifold: The manifold acts as the control center for the radiant floor heating system. It distributes hot water from the boiler or heat source to the tubing. Proper installation and connection of the manifold are crucial for efficient operation.

6. Pouring Concrete: After laying the tubing and connecting the manifold, a layer of concrete is poured over the top, encapsulating the tubing within. This concrete layer acts as a thermal mass, absorbing and radiating heat throughout the space.

7. Testing and Finishing: Once the concrete has cured, it is essential to test the system for leaks and proper functionality before applying finishes such as flooring materials or carpeting.

Frequently Asked Questions (FAQs):

1. Is radiant concrete floor heating suitable for all types of buildings?

Radiant concrete floor heating can be installed in various types of buildings, including residential homes, commercial spaces, and even industrial buildings. However, it is recommended to consult with a professional to determine if this heating method is suitable for your specific building.

2. Can radiant concrete floor heating be installed in existing homes?

Yes, radiant concrete floor heating can be retrofitted into existing homes . However, the installation process may be more complicated and require more extensive work compared to installing it in new construction. It is important to consult with a professional to assess the feasibility and requirements for retrofitting radiant concrete floor heating in your home.

3. How long does it take for the concrete to cure?

The time required for the concrete to cure can vary depending on various factors such as temperature, humidity, and the specific type of concrete used. In general, it can take anywhere from a few days to several weeks for the concrete to fully cure and reach its maximum strength.

4. Can radiant concrete floor heating be used with different flooring materials?

Yes, radiant concrete floor heating can be used with various types of flooring materials including tile, stone, hardwood, laminate, and even carpeting. However, it is important to consider the thermal conductivity of the flooring material and its compatibility with radiant heat. Some flooring materials may require additional insulation or underlayment to ensure efficient heat transfer.

5. Is radiant concrete floor heating energy-efficient?

Radiant concrete floor heating is known for its energy efficiency. By using the thermal mass of the concrete slab and distributing heat evenly throughout the space, it can provide comfortable heating while reducing energy consumption. Additionally, zoning capabilities allow for better control over different areas of a building, further enhancing energy efficiency.

6. Can radiant concrete floor heating be used for cooling as well?

Yes, radiant concrete floor heating systems can also be designed to provide cooling during hot summer months. This is achieved by circulating chilled water or using a hybrid system that combines radiant cooling with traditional air conditioning methods. The same tubing used for heating can be utilized for cooling purposes as well.

Overall, radiant concrete floor heating is a popular choice for its comfort, energy efficiency, and compatibility with different types of buildings and flooring materials. By following proper installation procedures and consulting with professionals, individuals can enjoy the benefits of this heating system in their homes or workplaces.