Most likely the simplest way to enhance the garage of yours is by the usage of floor mats created to cover whether part or even most of the floor region. I've seen that paint type on storage area flooring before and it seems really nice. It does not take up considerably more than a week's time to complete the task. At times this causes an issue, at times it doesn't.

Images about 2 Part Garage Floor Paint

If the garage of yours can be used far more as a show space you won't have to concern yourself with the same issues. Covering the floor with storage area floor tiles are able to lend the garage a snazzy appearance, and these're functional as well. Garage floor mats are affordable, enhance the appearance of the floor and are easy and quick to install. The result is a good way for storage area floor covering.

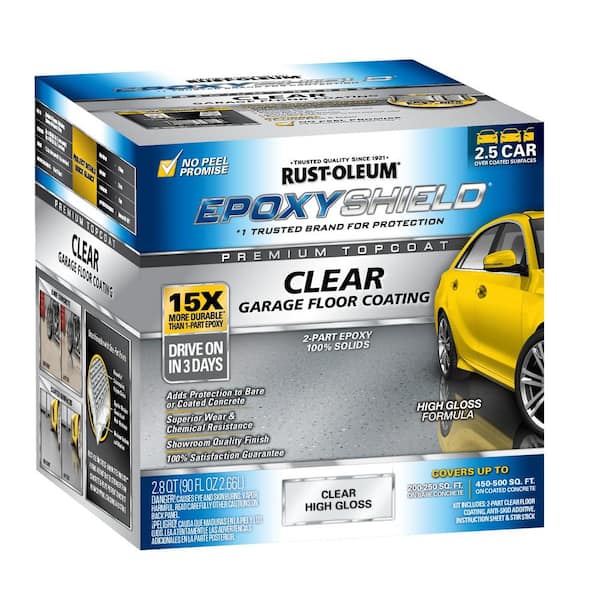

Rust-Oleum EpoxyShield 90 oz. Clear High-Gloss 2-Part Epoxy

This may in fact increase the value of the house of yours by 3 to 4 times the amount of money you would have to invest into your garage area renovation to make this a reality. They offer cabinets, shelves etc. The most widespread widths of rolled garage flooring are actually 7. Garage flooring is not a thing that everyone is knowledgeable about. It's not just cheaper, but may really well last longer.

Rust-Oleum EpoxyShield 2-part Gray Gloss Concrete and Garage Floor

Rust-Oleum EpoxyShield 2-part Gray Gloss Concrete and Garage Floor

2 part epoxy paint: Buy, Best, Floor, System, 2020 – Concrete

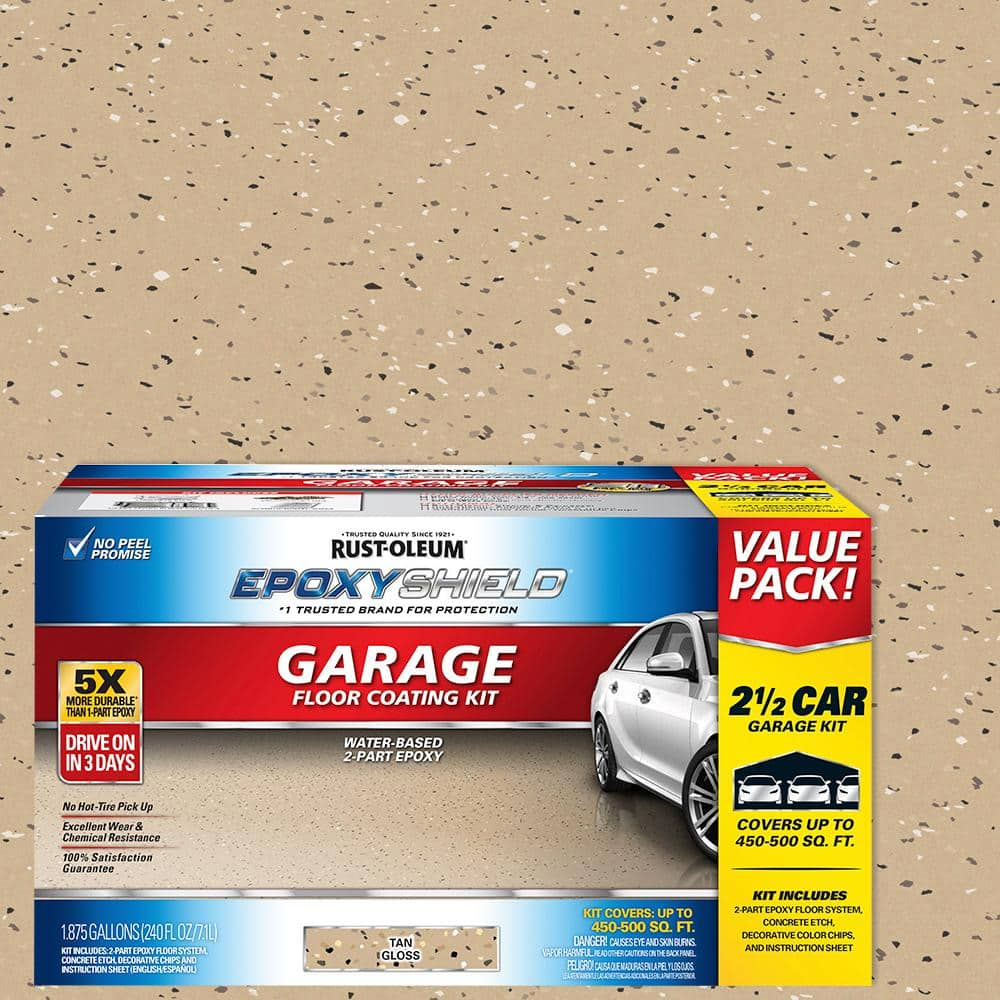

Rust-Oleum EpoxyShield 240 oz. Tan High-Gloss 2.5-Car Garage Floor Kit 365185

Rust-Oleum High performance 2-part Gray Gloss Concrete and Garage

Rust-Oleum EpoxyShield 90 oz. Clear High-Gloss 2-Part Epoxy

Garage Floor Epoxy Kit Concrete Coating Original Color Chips

BEHR PREMIUM 5 Gal. #ECC-10-2 Jet Black Self-Priming 1-Part Epoxy

Epoxy Paint u0026 Floor Coatings ArmorGarage

Flo-X Strong Arm 2-part Clear Gloss Concrete and Garage Floor

Rust-Oleum 261846 EPOXYSHIELD Garage Floor Coating, 2.5 Car Kit, Tan

Epoxy 2 gal. Water-Based Clear High Gloss 2-Part Epoxy Primer and Top Coat for Concrete Floors

Related Posts:

- Garage Floor Drains Covers

- Garage Floor Sealer Vs Epoxy

- Garage Floor Epoxy Systems

- Garage Floor Rebar Spacing

- Rustoleum Garage Floor Coating Dry Time

- Painting Garage Floor With Oil Stains

- Garage Floor Epoxy Repair

- Garage Floor Design Pictures

- Garage Flooring Discount

- G Floor Garage Floor Covering

2 Part Garage Floor Paint: Transform Your Garage with a Durable and Stylish Finish

Introduction:

The garage floor is often overlooked when it comes to home improvement projects. However, with the right paint, you can transform this space into a functional and aesthetically pleasing area. One popular choice for garage floor painting is 2 part garage floor paint. In this article, we will explore what exactly 2 part garage floor paint is, its benefits, how to apply it, and answer some frequently asked questions.

What is 2 Part Garage Floor Paint?

As the name suggests, 2 part garage floor paint consists of two components that need to be mixed together before application. The first component is epoxy resin, which provides durability and chemical resistance to the paint. The second component is a hardener that helps the paint cure and bond properly to the concrete surface. When these two parts are combined, they create a strong and long-lasting coating for your garage floor.

Benefits of 2 Part Garage Floor Paint:

1. Durability: One of the main advantages of using 2 part garage floor paint is its exceptional durability. This type of paint can withstand heavy traffic, resistant to chemicals, oil stains, and abrasion. It forms a tough protective layer that can prevent damage from vehicles, tools, and other equipment typically found in garages.

2. Longevity: Unlike traditional one-part paints, 2 part garage floor paint has a longer lifespan. Once cured, it forms a hard surface that can last for many years without chipping or peeling. This means you won’t have to worry about repainting your garage floor frequently.

3. Easy Maintenance: With 2 part garage floor paint, cleaning becomes a breeze. The smooth and seamless finish allows for easy sweeping and mopping. Any spills or stains can be quickly wiped away without leaving behind any residue or discoloration.

4. Chemical Resistance: Garage floors are often exposed to various chemicals like gasoline, oil, and solvents. 2 part garage floor paint is formulated to resist these substances, preventing them from penetrating the concrete and causing damage. This makes it an ideal choice for automotive enthusiasts or anyone working with chemicals in their garage.

5. Aesthetic Appeal: In addition to its functional benefits, 2 part garage floor paint can greatly enhance the overall appearance of your garage. It is available in a wide range of colors and finishes, allowing you to create a sleek and professional look that complements your personal style.

How to Apply 2 Part Garage Floor Paint:

Before applying 2 part garage floor paint, proper preparation is crucial to ensure a successful and long-lasting finish. Here are the steps involved in the application process:

1. Surface Preparation:

– Clear out the garage completely by removing any vehicles, tools, or other items.

– Thoroughly clean the floor by sweeping away loose debris and using a degreaser to remove any oil or grease stains.

– Repair any cracks or imperfections in the concrete using a patching compound specifically designed for garage floors.

– Etch the surface using an acid-based etching solution to open up the pores of the concrete, allowing better adhesion for the paint.

FAQ: Can I skip the surface preparation step?

No, surface preparation is essential for achieving a long-lasting finish with 2 part garage floor paint. Skipping this step may result in poor adhesion and premature peeling or chipping of the paint.

2. Mixing the Components:

– Read and Follow the manufacturer’s instructions for mixing the two components of the garage floor paint. This typically involves combining a resin and a hardener in specific ratios.

– Use a mixing paddle or a mechanical mixer to thoroughly mix the components together until they are well blended.

3. Application:

– Start by cutting in the edges of the floor using a brush or roller. This will create a clean and precise boundary for the main application.

– Pour the mixed paint onto the floor in small sections, spreading it evenly with a roller or squeegee. Work from one end of the garage to the other, ensuring complete coverage.

– Use a roller with a long handle to reach areas that are difficult to access, such as corners or under shelving units.

– Apply multiple coats if necessary, allowing each coat to dry completely before applying the next one. Follow the manufacturer’s recommended drying times.

4. Curing:

– Once all coats have been applied, allow the paint to cure for the recommended time period before subjecting it to heavy traffic or placing any items on the floor.

– Curing times can vary depending on temperature and humidity, so refer to the manufacturer’s instructions for specific guidance.

It is important to note that proper ventilation should be maintained during application and curing processes. Additionally, wearing protective equipment such as gloves and goggles is recommended to ensure safety.