They are available in many different colors so matching isn't a problem and you'll get exactly the same very long lasting durability that business industries get. You'll find a lot of different flooring businesses specializing in the software programs of epoxy resins. Epoxy floors coatings are versatile and high-performing because of the inherent chemical attributes of epoxy. Odds are actually that the concrete is actually damaged as well as tarnished.

Images about Bubbles In Epoxy Floor Coating

But there are different types of epoxy, and the choice of yours must be based on the amount of traffic goes by on your flooring from every day, exactly how regularly you will have to touch up, not to mention, the cost of every option. If you use epoxy flooring for people tough areas, you can rest certain that not simply will the surface look good for a very long time, but will take wear as well as tear like absolutely no other flooring material.

How to Get Bubbles out of Epoxy Brew Floors

Epoxy floors coatings are cheap compared with some other flooring coatings. While concrete is viewed as virtually indestructible, it is not impervious to certain types of damage, such as cosmetic, including scuffing, cracking and staining. But, if the area affected is substantial large, color mismatch will be evident. Hence, it is not designed for epoxy coating.

Bubbles in Epoxy Floors – Seven (7) Reasons Why are you getting

Read mixing instructions very carefully to insure proper ratios are mixed. Let us discuss some reason why you must choose this particular type of flooring product for the upcoming garage of yours or maybe dealer flooring task. Some of the kits are available with flakes to add to or perhaps scatter over the epoxy once it has been applied.

How To Repair Bubbles u0026 Craters in Epoxy u0026 Urethane Floors

Why Do Bubbles Form In The Epoxy Screed?

Bubbles on New Epoxy Floor The Garage Journal

Bubbles In Epoxy Flooring: Why This Happens (u0026 How To Fix It

Bubbles in Epoxy Floors: Understand the Causes

Osmotic blistering Knowledge Centre Respol

Bubbles In Epoxy Flooring: Why This Happens (u0026 How To Fix It

Epoxy Paint pinholes – air bubbles fisheyes

Key consideration for installation of an epoxy flooring system

How to stop pin holes, fish eyes and bubbles in epoxy coatings

Installing Epoxy Flooring

Related Posts:

- Remove Epoxy Coating From Concrete Floor

- High Build Epoxy Floor Coating

- Benefits Of Epoxy Garage Floor

- Epoxy Polyurethane Flooring Systems

- Epoxy Paint Floor Garage

- How To Clean Epoxy Coated Garage Floors

- Epoxy Garage Floor Coating On Wood

- Black Gloss Epoxy Flooring

- Epoxy Floor Paint Rustoleum

- Best Epoxy Floor Paint For Garage

Bubbles in Epoxy Floor Coating: Causes, Prevention, and Solutions

Epoxy floor coatings have become increasingly popular in residential, commercial, and industrial settings due to their durability, aesthetic appeal, and easy maintenance. However, one common issue that can arise during the application process is the presence of bubbles in the coating. These bubbles can detract from the overall appearance of the floor and compromise its quality. In this article, we will explore the causes of bubbles in epoxy floor coatings, preventative measures to avoid them, and effective solutions to eliminate them if they do occur.

I. Understanding the Causes of Bubbles in Epoxy Floor Coatings

1. Moisture Trapped Beneath the Surface:

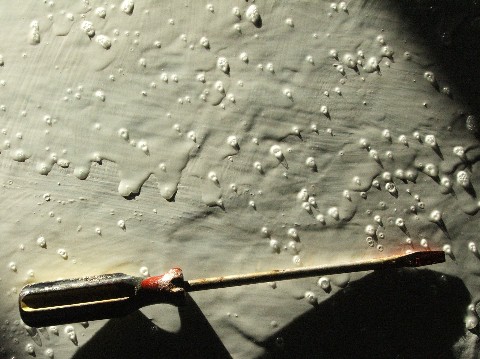

One of the primary reasons for bubbles forming in epoxy floor coatings is moisture trapped beneath the surface. This moisture can be present due to a variety of factors such as high humidity levels or improperly prepared concrete substrates. When the epoxy resin reacts with this trapped moisture, it releases gases that form bubbles within the coating.

FAQ: How can I prevent moisture-related bubbles in epoxy floor coatings?

To prevent moisture-related bubbles, it is crucial to ensure that the concrete substrate is adequately prepared before applying the epoxy coating. This involves thoroughly cleaning and drying the surface, performing a moisture test using a calcium chloride kit or plastic sheet test, and addressing any excessive moisture issues before proceeding with the coating application.

2. Improper Mixing of Epoxy Components:

Another common cause of bubbles in epoxy floor coatings is improper mixing of the epoxy components. Epoxy resin consists of two parts – resin and hardener – that need to be mixed together in precise proportions to achieve optimal results. If these components are not mixed thoroughly or accurately measured, it can lead to incomplete chemical reactions and subsequent bubble formation.

FAQ: How can I prevent bubbles caused by improper mixing?

To avoid bubbles caused by improper mixing, carefully follow the manufacturer’s instructions regarding the mixing ratios and procedures. Use a clean, calibrated mixing container and thoroughly stir the components together for the recommended duration. Additionally, avoid introducing air into the mixture by stirring slowly and avoiding aggressive agitation.

3. Air Entrapment During Application:

During the application of epoxy floor coatings, air can become entrapped within the coating due to improper techniques or equipment. This can occur when rolling or brushing the epoxy onto the surface too quickly or vigorously, causing air to be forced into the coating and creating bubbles.

FAQ: How can I prevent air entrapment during application?

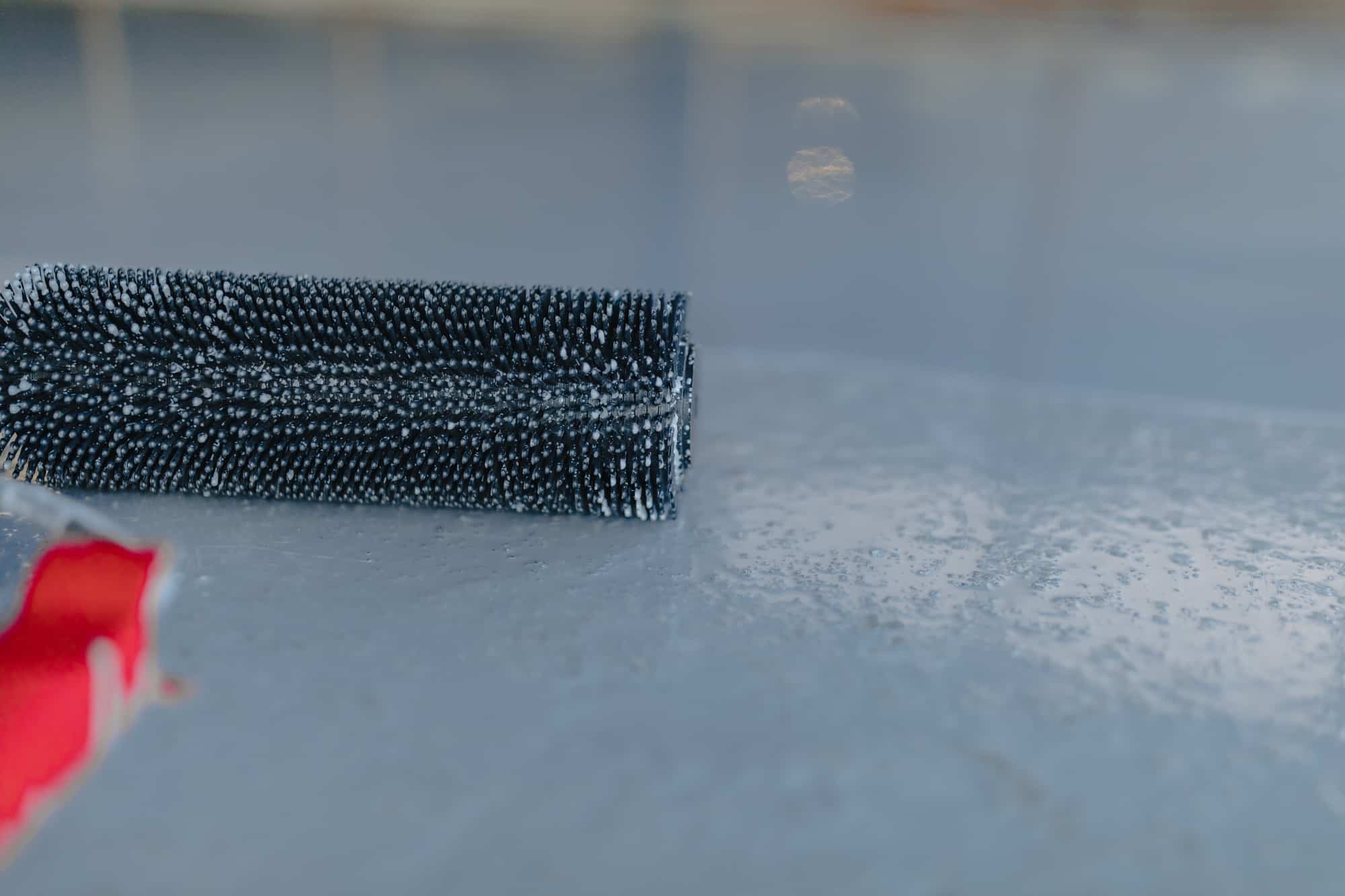

To prevent air entrapment, it is essential to apply the epoxy in a controlled manner. Begin by pouring the mixed epoxy onto the floor and spreading it evenly using a notched squeegee or roller. Then, use a spiked roller or bubble-busting roller to eliminate any trapped air by rolling over the freshly applied epoxy in a crosshatch pattern.

II. Preventative Measures to Avoid Bubbles in Epoxy Floor Coatings

1. Proper Surface Preparation:

Proper surface preparation is key to preventing bubbles in epoxy floor coatings. Start by thoroughly cleaning the concrete substrate to remove any dirt, oil, or grease that could interfere with adhesion. Next, repair any cracks or imperfections in the concrete using an appropriate filler compound. Finally, etch or mechanically abrade the surface to create a profile that promotes strong bonding between the epoxy and substrate.

2. Moisture Testing:

Before applying an epoxy floor coating, it is crucial to perform moisture testing on the concrete substrate To ensure that excessive moisture is not present. This can be done using a moisture meter, calcium chloride kit, or plastic sheet test. If high levels of moisture are detected, steps should be taken to address the issue before proceeding with the coating application, such as applying a moisture barrier or using a moisture-tolerant epoxy formula.

3. Proper Mixing Techniques:

To prevent bubbles caused by improper mixing, it is important to carefully follow the manufacturer’s instructions for mixing ratios and procedures. Use clean, calibrated mixing containers and stir the components together thoroughly for the recommended duration. Avoid introducing air into the mixture by stirring slowly and gently, and consider using a mechanical mixer if available.

4. Controlled Application Techniques:

During the application of epoxy floor coatings, it is important to apply the epoxy in a controlled manner to prevent air entrapment. Pour the mixed epoxy onto the floor and spread it evenly using a notched squeegee or roller. Then, use a spiked roller or bubble-busting roller to eliminate any trapped air by rolling over the freshly applied epoxy in a crosshatch pattern. Work in small sections at a time to ensure thorough coverage and minimize the chances of bubbles forming.

5. Proper Cure Time and Conditions:

After applying the epoxy floor coating, allow it to cure according to the manufacturer’s instructions. This typically involves letting it dry undisturbed for a specified period of time and under recommended temperature and humidity conditions. Rushing the curing process or exposing the coating to extreme conditions can increase the likelihood of bubbles forming.

By following these preventative measures and taking careful steps during surface preparation, mixing, application, and curing, you can minimize the risk of bubbles forming in your epoxy floor coatings and achieve a smooth, professional finish.