Polished concrete flooring is an excellent strategy to wisely use resources. Concrete floor takes some time to loosen up, but is quite economical from having that heat in, meaning the house will continue to be warm on winter nights. Maintaining your concrete floor coating is very simple. Polished concrete floors are very simple to maintain as well as look after.

Images about Concrete Floor Construction Insulation

Nevertheless, visual appeal and the functionality of concrete could possibly be hampered by its useful protection aspects, especially for kids which are younger. When included in basements, having bare concrete floors is an even more hygienic alternative from moldy carpets & rugs.

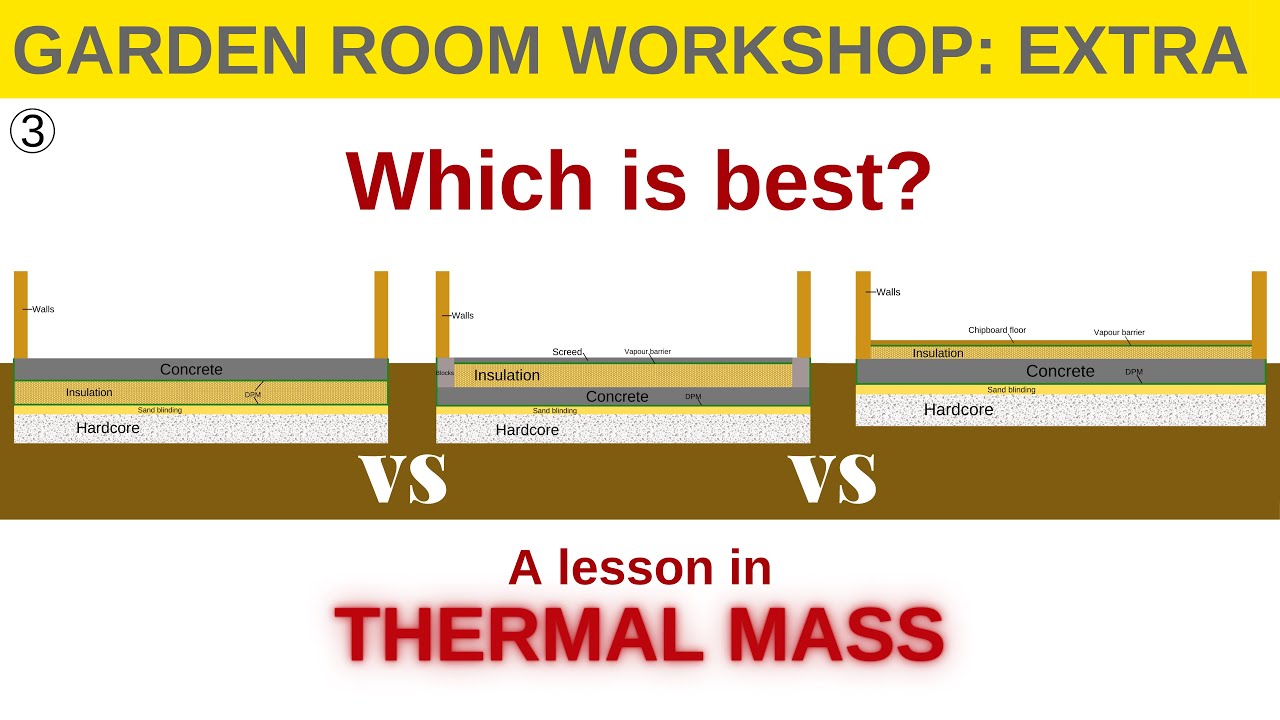

Garden Room Workshop Extra Insulating A Concrete Slab

Damp polishing creates waste slurry which easily transfers into hard-to-find tough to reach locations. On a brand new concrete, stain concrete flooring surfaces suppliers advise letting the concrete treatment for at least a month. Aside from making polished concrete extremely renewable, concrete is definitely the cheapest flooring choice offered.

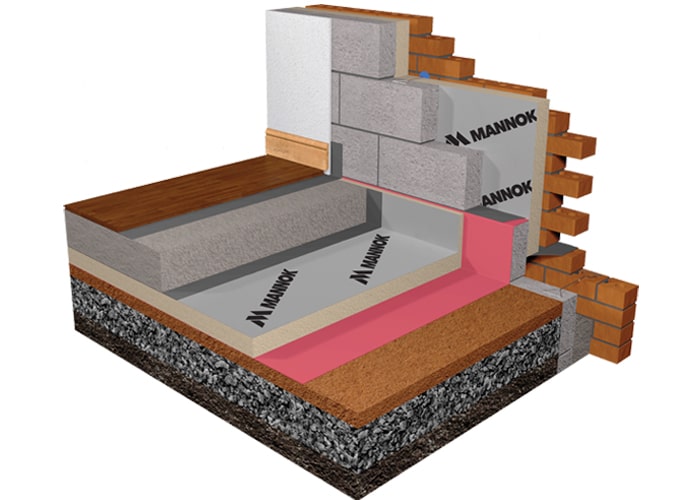

Floor Insulation – Mannok

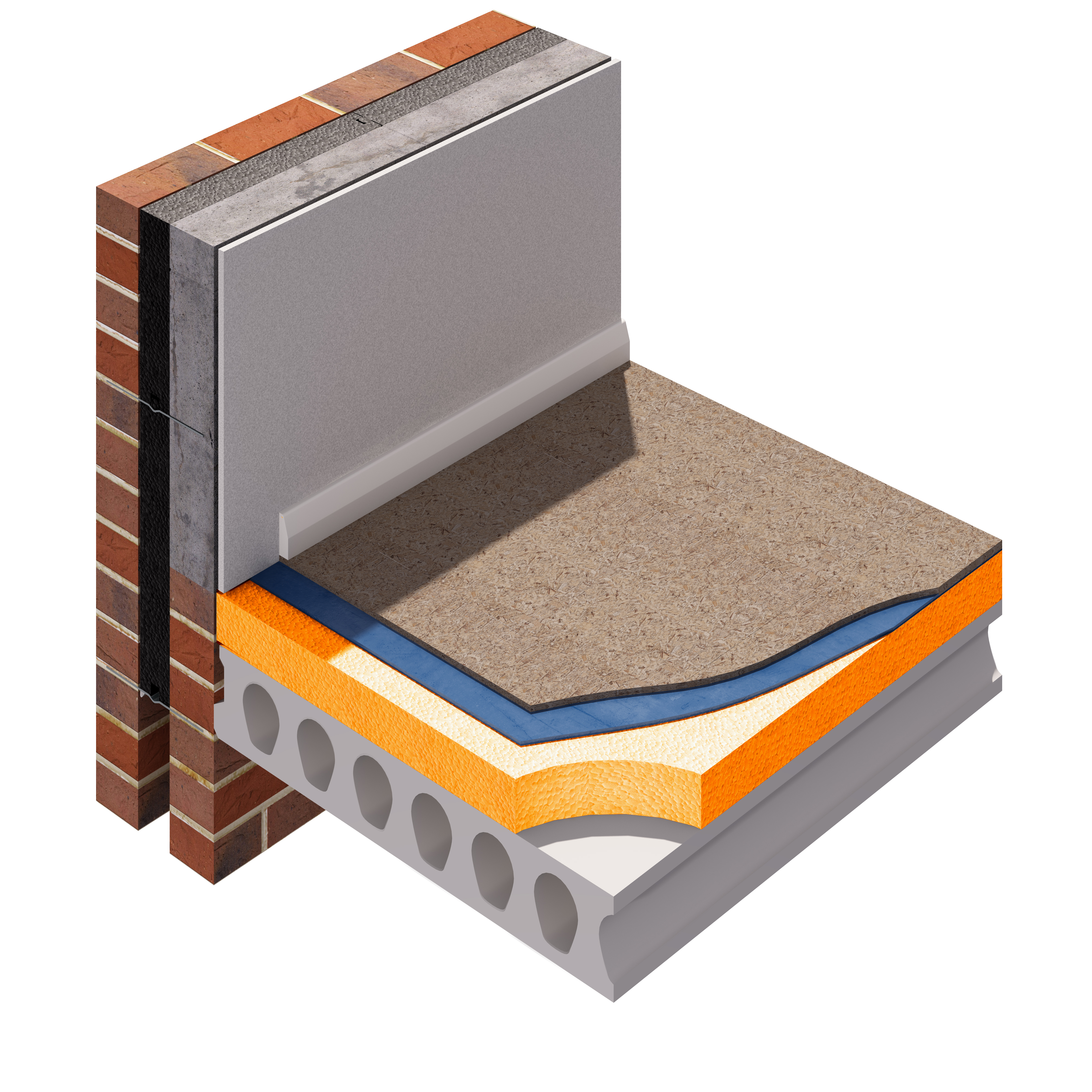

Thermal Insulation for Concrete Slab Floors

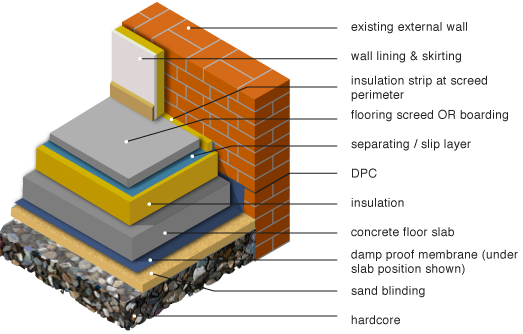

Insulation for ground floors – Designing Buildings

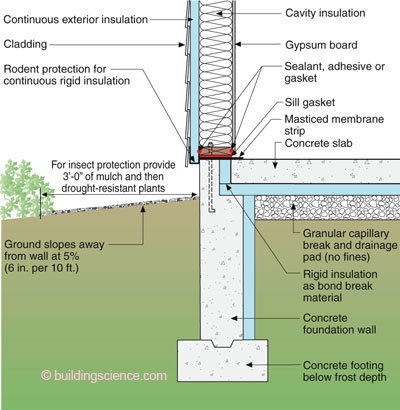

Slab Happy u2013 Concrete Engineering Building Science

Details for Insulating a Slab Perimeter – GreenBuildingAdvisor

Concrete Floor Insulation Clearance, 56% OFF www.ingeniovirtual.com

Basement Flooring – How To Insulate A Concrete Floor

GreenSpec: Housing Retrofit: Ground Floor Insulation

How to Insulate a Raised Floor – GreenBuildingAdvisor

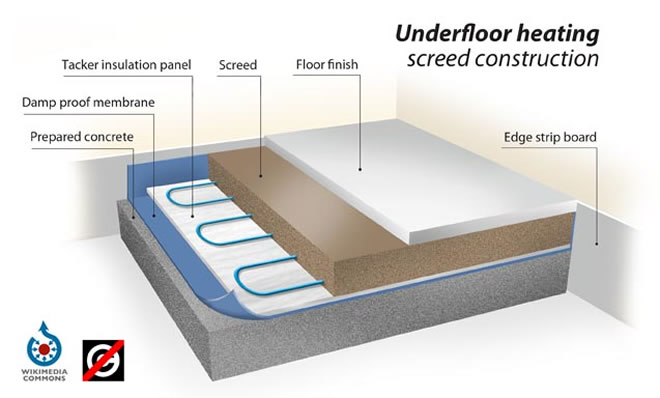

diagram of structural concrete slab floor with underfloor heating

Articles and Advice Insulation Kingspan Great Britain

Installation of rigid floor insulation on ground floor concrete

Related Posts:

- Knee Pads For Concrete Floors

- Concrete Floor Finishing Techniques

- Concrete Floor Minimum Thickness

- Concrete Floor Radiant Heat Installation

- Pitted Concrete Floor

- Concrete Floor Stain Remover

- How To Keep Concrete Floors Warm

- Concrete Floor Paint Colors Ideas

- How To Seal New Concrete Floor

- Exposed Concrete Floor Finish

Concrete Floor Construction Insulation: A Comprehensive Guide

Introduction:

Insulating concrete floors is a crucial step in creating energy-efficient buildings. It not only helps in maintaining a comfortable indoor temperature but also contributes to reducing energy consumption and lowering utility bills. In this article, we will delve into the various aspects of concrete floor construction insulation, including its importance, types of insulation materials, installation methods, and frequently asked questions.

I. Importance of Concrete Floor Insulation:

Insulating concrete floors offers numerous benefits in terms of thermal comfort, energy efficiency, and soundproofing. Let’s explore these advantages in detail:

1. Thermal Comfort:

Concrete floors tend to absorb and retain cold temperatures during winters, making them uncomfortable to walk on. By insulating the floor, you can minimize heat loss and ensure a warm living environment. Additionally, insulation prevents excessive heat gain during summers, keeping the indoor space cool.

2. Energy Efficiency:

Insulated concrete floors act as a barrier against heat transfer between the ground and the building’s interior. This reduces the need for heating or cooling systems to work harder, resulting in significant energy savings. Consequently, insulating your concrete floor contributes to a greener and more sustainable future.

3. Soundproofing:

Concrete floors can transmit noise from foot traffic or machinery to other parts of the building. Installing insulation helps in sound absorption, creating a quieter environment within the premises. This is particularly beneficial for residential buildings or commercial spaces where noise reduction is essential.

II. Types of Insulation Materials for Concrete Floors:

Choosing the right insulation material is crucial for effective thermal performance. Here are some commonly used insulation materials suitable for concrete floor construction:

1. Expanded Polystyrene (EPS):

EPS foam boards are lightweight yet durable insulation materials that are easy to handle during installation. They have excellent thermal properties and can withstand heavy loads without compressing over time. EPS insulation is available in various thicknesses and can be easily cut to fit the desired dimensions.

2. Extruded Polystyrene (XPS):

Similar to EPS, XPS foam boards offer excellent insulation properties and high compressive strength. They are moisture-resistant, making them ideal for areas prone to dampness, such as basements or crawl spaces. XPS insulation is available in various thicknesses, allowing customization according to specific project requirements.

3. Polyurethane Foam (PUR):

Polyurethane foam is a versatile insulation material that can be sprayed or poured onto concrete surfaces. It expands rapidly upon application, filling gaps and crevices, ensuring a seamless insulation layer. PUR foam provides superior thermal resistance and acts as an effective vapor barrier, preventing moisture infiltration.

4. Mineral Wool:

Mineral wool insulation is made from natural or recycled materials such as rock or slag fibers. It offers excellent thermal and acoustic properties, making it suitable for both thermal insulation and soundproofing purposes. Mineral wool is available in batts or rolls, making it easy to install between joists or beneath the concrete slab.

III. Installation Methods for Concrete Floor Insulation:

Proper installation of insulation plays a vital role in maximizing its effectiveness. Here are two commonly used methods for insulating concrete floors:

1. Below-Slab Insulation:

In this method, insulation is installed beneath the concrete slab during the initial construction phase. It involves placing rigid foam boards or laying down mineral wool between the ground and the concrete base. This method provides continuous insulation throughout the entire floor area and minimizes heat loss through the ground.

FAQs: Q1. Why is insulation important for concrete floors?

A1. Insulation helps in sound absorption and creates a quieter environment within the premises. It also provides thermal resistance, reducing heat loss through the floor.

Q2. What are some commonly used insulation materials for concrete floors?

A2. Some commonly used insulation materials for concrete floors include Expanded Polystyrene (EPS), Extruded Polystyrene (XPS), Polyurethane Foam (PUR), and Mineral Wool.

Q3. What are the benefits of EPS insulation?

A3. EPS insulation is lightweight, durable, and easy to handle during installation. It has excellent thermal properties and can withstand heavy loads without compressing over time.

Q4. Why is XPS insulation suitable for areas prone to dampness?

A4. XPS foam boards are moisture-resistant, making them ideal for areas prone to dampness such as basements or crawl spaces.

Q5. What are the advantages of using polyurethane foam for concrete floor insulation?

A5. Polyurethane foam can be sprayed or poured onto concrete surfaces, providing a seamless insulation layer. It offers superior thermal resistance and acts as an effective vapor barrier.

Q6. How is mineral wool insulation beneficial for concrete floors?

A6. Mineral wool insulation offers excellent thermal and acoustic properties, making it suitable for both thermal insulation and soundproofing purposes. It is easy to install between joists or beneath the concrete slab.

Q7. What is below-slab insulation?

A7. Below-slab insulation involves installing insulation beneath the concrete slab during the initial construction phase. This method provides continuous insulation throughout the entire floor area and minimizes heat loss through the ground.