Stained concrete floors comes in remarkable colors so in case you like colors, this is a proper choice for you personally. You are able to toy with patterns on stained concrete floors. There are numerous businesses that deal in polished floors and they promote a number of accessories like cleaning devices which will help one to manage the polished concrete floor of theirs rather sufficiently.

Images about Concrete Floor Resurfacing Products

But on the upside of things, and also for a big change, concrete floor might actually look really good in case it is completed properly. Polished concrete floors unlike some other floors offer significantly less maintenance and its reflective nature maximizes organic light saving you considerable amount of power. Concrete floors could be painted, stained, glossed or perhaps improved with other materials as preferred by the household.

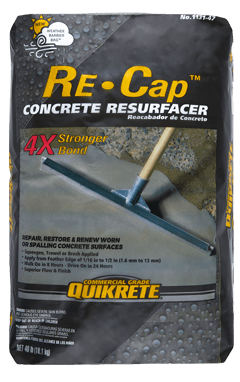

Concrete Resurfacer QUIKRETE: Cement and Concrete Products

This particular kind of system works to prevent permanent degeneration of finished concrete floors. No matter what may leak on it or perhaps be dragged across it, concrete flooring is nearly indestructible. If you are thinking that you would like to have a lot more options than just a glossy surface as well as color to work into the design objectives of yours, subsequently polished concrete is still the technique to go.

Top 20 Best New Home Products Building Materials Concrete

Resurface and Patch Concrete Surfaces

How to Resurface Concrete in 4 Steps – This Old House

/cdn.vox-cdn.com/uploads/chorus_asset/file/19497926/howto_concrete_04.jpg)

New Concrete Overlay Technique Leggari Products

The Best Concrete Resurfacers to Bring Sidewalks, Patios, and

Self-Leveling Concrete Can Save Both Time and Money – Concrete Decor

How to Decide Whether to Repair or Replace Your Concrete For

QUIKRETE® – Concrete Resurfacer

Garage Floor Resurfacing: Fix a Pitted Garage Floor (DIY) Family

How to Refinish Concrete Floors in a Basement – Semigloss Design

Floor Patch u0026 Resurfacing Floor Repair Products QuestMark

Rapid Set 25 lbs. NewCrete Concrete Resurfacer 05020025

Related Posts:

- How To Get Polished Concrete Floor

- Easy Concrete Floor Ideas

- Heated Concrete Floor Tubing

- Indoor Stamped Concrete Floor

- How To Tile Over Concrete Floor

- Concrete Floor Heating And Cooling

- Stained Concrete Floor Tiles

- Outdoor Concrete Floor Coverings

- Stained Concrete Floors Cleaning

- Concrete Floor Garage Paint

Concrete Floor Resurfacing Products: Revitalize Your Space with Durability and Style

Introduction:

Concrete floors are known for their durability and low maintenance. However, over time, they can become worn, cracked, or stained, diminishing the overall appearance of a space. Concrete floor resurfacing products offer a cost-effective solution to breathe new life into your floors while providing enhanced durability and aesthetic appeal. In this article, we will explore the various types of concrete floor resurfacing products available in the market, their applications, and the benefits they offer.

I. Understanding Concrete Floor Resurfacing:

a) What is concrete floor resurfacing?

Concrete floor resurfacing is a process of applying a new layer of material over an existing concrete surface to repair any damage, improve its appearance, and increase its longevity. It involves the use of specialized products designed to bond with the existing concrete and provide a smooth and durable finish.

b) When is concrete floor resurfacing necessary?

Concrete floor resurfacing is necessary when the existing concrete starts showing signs of wear and tear such as cracks, spalling, or surface imperfections. It is also beneficial when there are stains or discoloration that cannot be removed through regular cleaning methods. Additionally, resurfacing can be done to update the look of a space or to enhance its functionality.

II. Types of Concrete Floor Resurfacing Products:

a) Polymer-modified overlays:

Polymer-modified overlays are one of the most popular choices for concrete floor resurfacing. These products consist of a blend of cement, polymers, aggregates, and other additives that create a thin yet highly durable layer over the existing concrete surface. They adhere well to the substrate and offer excellent resistance against abrasion, chemicals, UV rays, and moisture.

FAQs:

– Can polymer-modified overlays be applied on both interior and exterior surfaces?

Yes, polymer-modified overlays are versatile and can be used for both indoor and outdoor applications. They are suitable for residential, commercial, and industrial spaces.

– How thick should the polymer-modified overlay be?

The thickness of the overlay depends on the specific product and application requirements. Generally, it ranges from 1/16 inch to 1/4 inch. Thicker overlays are recommended for high-traffic areas or when additional strength is required.

b) Microtoppings:

Microtoppings are thin cementitious overlays that provide a smooth and uniform finish to the concrete surface. They are typically applied at a thickness of around 1/8 inch to 1/4 inch and can be customized with decorative patterns or colors. Microtoppings are an excellent choice for revitalizing worn-out concrete floors while preserving their structural integrity.

FAQs:

– Can microtoppings be used on outdoor surfaces?

While microtoppings can be used outdoors, they may require additional protective coatings to withstand harsh weather conditions and UV exposure.

– Are microtoppings suitable for areas with heavy foot traffic?

Microtoppings can withstand moderate foot traffic, but in high-traffic areas, it is advisable to use thicker overlays or consider other resurfacing options such as epoxy coatings or polyurethane sealers.

c) Epoxy coatings:

Epoxy coatings offer exceptional durability, chemical resistance, and a glossy finish to concrete floors. These products consist of a two-part epoxy resin that is mixed just before application. The resulting mixture creates a strong bond with the concrete surface, forming a Hard and seamless coating that can withstand heavy foot traffic, abrasion, and spills. Epoxy coatings are commonly used in commercial and industrial settings, but they can also be applied in residential spaces for a sleek and modern look.

FAQs:

– Can epoxy coatings be applied on existing concrete with cracks?

Yes, epoxy coatings can be applied on concrete with cracks. However, it is important to properly repair and fill the cracks before applying the coating to ensure a smooth and even surface.

– How long does it take for epoxy coatings to cure?

The curing time for epoxy coatings depends on various factors such as temperature, humidity, and the specific product used. Typically, it takes around 24 to 72 hours for the coating to fully cure and reach its maximum strength.

d) Polyurethane sealers:

Polyurethane sealers are clear protective coatings that provide excellent resistance against stains, chemicals, and UV rays. They are typically applied over existing concrete surfaces to enhance their appearance and protect them from wear and tear. Polyurethane sealers are easy to apply and maintain, making them a popular choice for both indoor and outdoor applications.

FAQs:

– Can polyurethane sealers be applied over other resurfacing products?

Yes, polyurethane sealers can be applied over polymer-modified overlays, microtoppings, or epoxy coatings to provide an additional layer of protection and enhance their durability.

– How often do polyurethane sealers need to be reapplied?

The lifespan of polyurethane sealers can vary depending on factors such as the level of foot traffic, exposure to sunlight, and the quality of the product. Generally, they may need to be reapplied every 1 to 3 years for optimal performance and protection.