Some additional detriments to installing unfinished hardwoods are actually: the vapors linked to finishing the floor on site, the decreased amount of coats being used as well as the absence of ability to seal the finish with the help of the UV light process. This artificial substance serves as the bottom layer and it is generally impervious to moisture. For hundreds of years, hardwood floors have been gracing magnificent homes through the Deep South to stylish homes of kings and queens.

Images about Engineered Hardwood Flooring Veneer Thickness

/cdn.vox-cdn.com/uploads/chorus_asset/file/19489671/02_about_wood_floors_x.jpg)

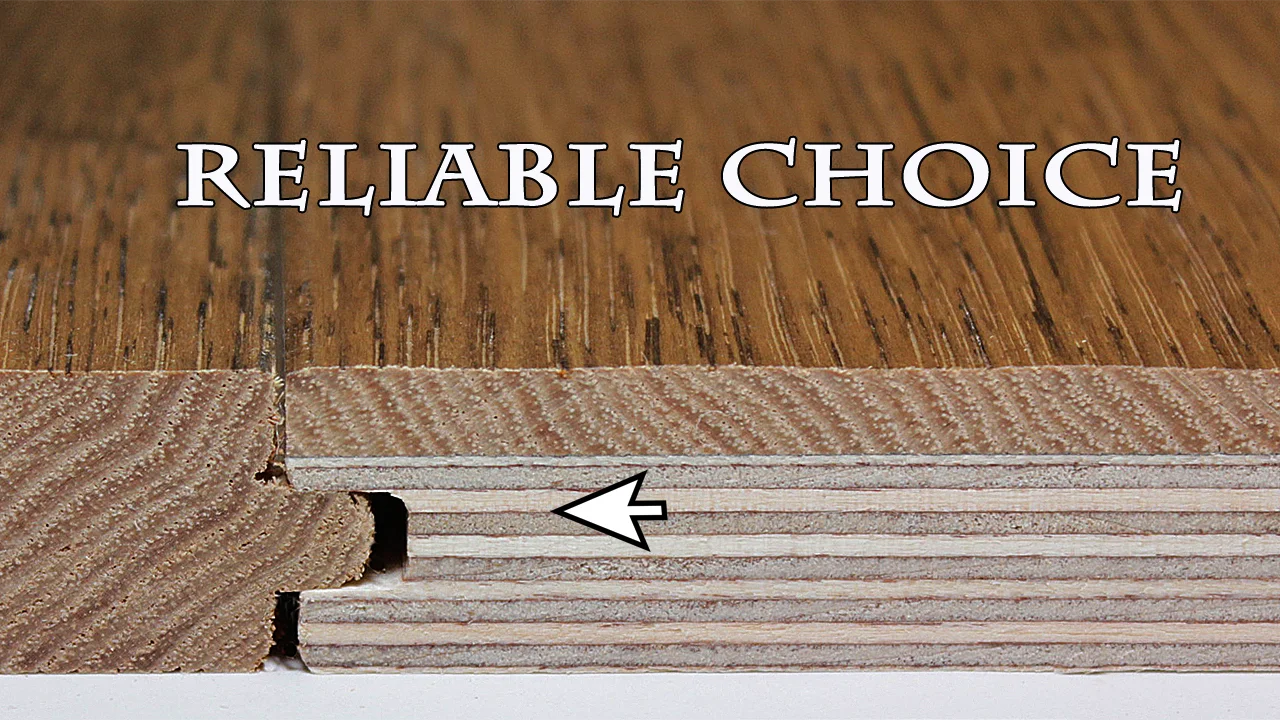

Usually, lower end flooring will have shorter pieces. And sturdy hardwood flooring has a soothing healthy warmth and beauty which simply can't be compared to any other kind of flooring now. Effectively, that's not every thing it requires. Engineered hardwood flooring is a program made of a center of hardwood, plywood, or maybe large density fiber along with a top-layer of hardwood veneer that is glued on the top surface area of the core.

3/4″ Inch Thick Engineered. Baltic Birch Ply – 5.8 mm Wear Layer

Before getting into the helpful suggestions on hardwood flooring, it is just right to initially explore why you will wish to think about the type of flooring in the earliest place. If you did a really good job of installing your hardwood flooring using the glue down method, you won't encounter almost as a lot of creaky floor syndrome as you'd with other methods of installation.

EXPERT Engineered – Lauzon Hardwood Flooring

All About Engineered Wood Flooring

4 Things You Must Know Before You Buy an Engineered Wood Floor

Engineered Flooring – Custom Options

All About Wear Layers – Engineered Flooring

How Thick Should Engineered Wood Flooring Be? PRO! Flooring

Why Engineered Wood Floors Are Not Made Equal Unique Wood Floors

allen + roth Allen+Roth Hardwood Gunstock Oak 5-in Wide x 3/8-in Thick Smooth/Traditional Engineered Hardwood Flooring (19.69-sq ft)

3/4 Inch Engineered 2019

HOMELEGEND Gunstock Oak 3/8 in. Thick x 5 in. Wide x Varying

allen + roth Allen+Roth Hardwood Gunstock Oak 5-in Wide x 3/8-in

Wimbley Birch 1/2″ Thick x 5″ Wide x Varying Length Engineered Hardwood Flooring

Related Posts:

- Hardwood Floors That Are Dog Proof

- Hardwood Floor Remove Scratches

- Handscraped Maple Hardwood Flooring

- Hardwood Floor Refinishing Drying Time

- Brazilian Hardwood Flooring Reviews

- Installing Hardwood Floors In Existing Kitchen

- Hardwood Floor Nailer Bostitch

- Hardwood Flooring Depot Reviews

- Best Maple Hardwood Flooring

- Hardwood Floor Steam Cleaning Machines

Introduction

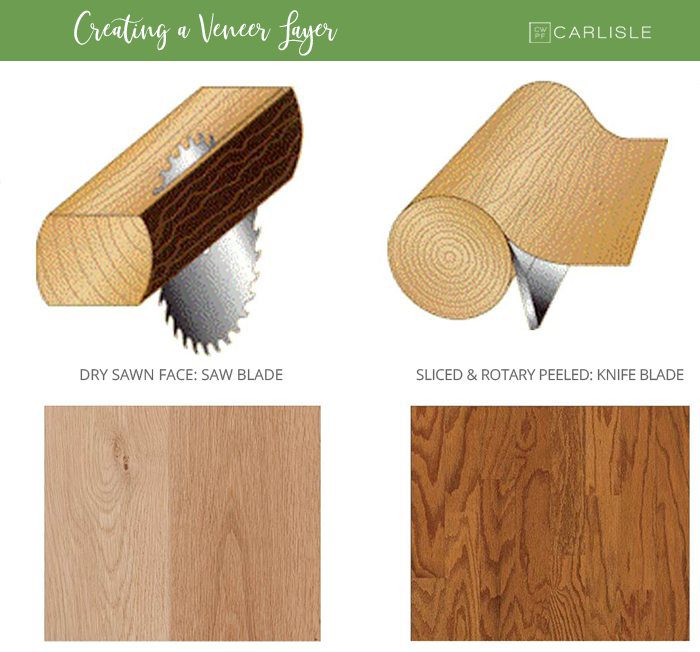

Engineered hardwood flooring is a popular choice for today’s homeowners. It has all the beauty and character of traditional hardwood, but with additional benefits like stability and durability. One of the key characteristics that determine the quality of engineered hardwood flooring is the veneer thickness. In this article, we’ll discuss what veneer thickness is, why it matters, and what to look for when selecting your engineered hardwood flooring.

What is Veneer Thickness?

Veneer thickness refers to the top layer of wood used in engineered hardwood flooring. This layer is also known as the wear layer or top layer, and it determines how durable and long-lasting your engineered hardwood flooring will be. The thicker the veneer, the more resistant your floors will be to scratches, dents, and general wear-and-tear.

The Benefits of a Thicker Veneer

When considering engineered hardwood flooring, it’s important to consider not only the species of wood used but also the veneer thickness. A thicker veneer offers several benefits over thinner veneers, including:

• Greater Durability: A thicker veneer makes your floors more resistant to scratches, dents, and other types of wear-and-tear. This means your floors will last longer and require less maintenance over time.

• Better Aesthetics: Thicker veneers create a more natural look on your floors. The deeper grain patterns offered by thicker veneers add texture and depth to your floors that can’t be achieved with thinner alternatives.

• Increased Resale Value: Installing thicker veneers can increase the value of your home should you decide to put it on the market in the future. Homebuyers are willing to pay more for homes with higher quality flooring, so investing in a thicker veneer now could pay off in the future.

What Thickness Should You Choose?

When choosing an engineered hardwood flooring with a thick veneer, there are a few things you should keep in mind. Generally speaking, you should look for a veneer between 3mm and 6mm thick for residential applications. If you plan on using your floors in high traffic areas or commercial settings, then you may want to consider a thicker veneer (7mm or 8mm). However, keep in mind that thicker veneers come with a higher price tag so make sure you factor this into your budget before making your purchase decision.

FAQs About Engineered Hardwood Floor Veneers

Q: What is an engineered hardwood floor?

A: An engineered hardwood floor is made up of several layers of wood glued together under pressure to form a single plank. The top layer (also known as the wear layer) consists of a thin piece of real wood called a “veneer” that gives each plank its unique look and character. While there are other components beneath the top layer such as plywood or high-density fiberboard (HDF), these do not affect the overall look or feel of the plank when installed on your floors.

Q: What are some advantages of using an engineered hardwood floor ?

A: Engineered hardwood floors offer several advantages when compared to traditional hardwood flooring. For starters, engineered hardwood floors are more dimensionally stable and less prone to warping or shifting due to changes in humidity or temperature. Additionally, engineered hardwood floors are typically easier to install than solid hardwood floors, making them a great option for DIYers. Finally, engineered hardwood floors provide a beautiful look at an affordable price point.

What is the difference between engineered hardwood flooring and laminate flooring?

Engineered hardwood flooring is made up of multiple layers of wood and other materials, such as resin, bonded together to create a single, solid piece. The top layer is a wood veneer that is available in various species and colors. Engineered hardwood flooring is more durable than traditional hardwood and can be installed directly over concrete or existing floors.Laminate flooring is also composed of multiple layers that are fused together. The top layer is a high-resolution image that simulates the look of natural wood or stone. Laminate flooring is much less expensive than engineered hardwood and is more resistant to moisture and scratches. It can also be installed directly over existing floors.

What are the advantages and disadvantages of engineered hardwood flooring compared to laminate flooring?

Advantages of Engineered Hardwood Flooring:– Natural wood look and feel

– Long lasting and durable

– Easy to install

– Resistant to moisture, scratches, and dents

– Can be sanded and refinished several times

– Environmentally friendly

Disadvantages of Engineered Hardwood Flooring:

– More expensive than laminate flooring

– Can be damaged by excess water or moisture

– Can be noisy when walked on

– Needs regular maintenance to keep it looking its best

Advantages of Laminate Flooring:

– Cheaper than engineered hardwood flooring

– Easier to install

– Resistant to moisture and staining

– Low maintenance

Disadvantages of Laminate Flooring:

– Not as durable as engineered hardwood flooring

– Can’t be sanded or refinished like hardwood flooring

– Not as natural looking as hardwood flooring