Throughout the winter months, it is going to be much colder and definitely the air in the house is a great deal drier than the summer months which in turn brings about very small spaces appearing in between the single planks as the wood contracts. Trees are a renewable resource we are able to utilize for a long time to come. These specification are discussed in more detail at our website.

Images about Engineered Wood Flooring Glue Or Float

While relatively pricier compared to typical laminated engineered wood floor surfaces, reclaimed engineered wood flooring has received reviews that are positive from individuals that have paid for as well as set up this "span of history" floors with total satisfaction as well as overall strong tips. It is essential to hire a pro installation team that is acquainted with wood and the reaction of its to moisture.

Should You Float or Glue Down Your Wood Flooring? u2014 Inner Space

Antique and Reclaimed wood floors are an ever well-known trend in flooring. Several planks are usually wider boards and have a character along with charm which display an instinctive sense of spirit and harmony of country living. It looks, for all of the world, as in case your flooring has been laid for a long time and adds a specific authenticity to the home of yours. Of course different houses lend themselves to different woods.

Floating Vs. Glue-Down Wood Flooring [Pros u0026 Cons]

Floating Vs. Glue-Down Wood Flooring [Pros u0026 Cons]

Floating Floor vs. Nail Down Slaughterbeck Floors, Inc.

Floating Vs. Glue-Down Wood Flooring [Pros u0026 Cons]

Floating Vs. Glue-Down Wood Flooring [Pros u0026 Cons]

Floating Floor vs. Nail Down Slaughterbeck Floors, Inc.

Float vs. Glued vs. Nail-Down Flooring: Which is Best u0026 Why?

Floating Floors Pros and Cons

/what-is-a-floating-floor-1821740-hero-00e6b7fe102e4fafa8ba3f926944bcb7.jpg)

Which Method Should I Use to Install My Engineered Wood Floor

Should You Float Or Glue Your Engineered Wood Flooring?

All About Floating Wood Floors

Floating Wood Floor: Install One in 8 Steps – This Old House

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/19493650/0405_flooring_illo.jpg)

Related Posts:

- Engineered Wood Flooring Scratch Resistant

- Armstrong Proconnect Wood Flooring Adhesive

- Wood Floor Chevron Pattern

- Wood Floor Cleaner Pledge

- Jasper Wood Flooring Reviews

- Unfinished Wood Flooring Vs Prefinished

- Dark Wood Floor Scratch Repair

- Wood Floor Warping Repair

- Grey Wood Floor In Bathroom

- Homemade Wood Floor Cleaner Shine

Introduction

Engineered wood flooring has grown in popularity over the years, as it offers many advantages over traditional hardwood flooring. One of the primary decisions homeowners must make when installing engineered wood flooring is whether to “glue or float” the flooring planks. This article will discuss both options in detail, so you can make an informed decision about which installation method is best for your home.

What is Glue-down Installation?

Glue-down installation is the process of installing engineered wood flooring directly to the subfloor using a quality adhesive. This method provides stability and durability, and gives homeowners the flexibility to install their flooring in any room of their home. The downside to this installation method is that it requires more time and effort than floating, and can be more expensive due to the cost of adhesives.

Advantages of Glue-down Installation

The major advantage of glue-down installation is that it provides a secure bond between the planks of engineered wood flooring and the subfloor. This bond helps to prevent shifting or movement of the planks, which can occur when floating, and also helps to reduce noise transfer from one room to another. The glue also helps create a moisture barrier between the planks and subfloor, which is especially important in areas prone to high levels of humidity.

Disadvantages of Glue-down Installation

The main disadvantage of glue-down installation is that it requires more time and effort than floating. As mentioned above, adhesives are needed for this installation method, and careful preparation must be taken when applying them correctly. It also takes longer for glued planks to dry compared to those installed with a floating method, as any adhesive residue must be completely dry before the flooring can be walked on. Additionally, gluing down engineered wood flooring can increase costs due to the need for adhesives.

FAQs About Glue-Down Installation

Q: What kind of adhesive should I use for glue-down installation?

A: When choosing an adhesive for your engineered wood flooring project, make sure it is specifically designed for use with your type of subfloor (concrete, plywood or particleboard). Select a product with high moisture resistance and check that it meets all local building codes before purchasing. If you are unsure what type of adhesive will work best for your project, consult a professional installer or your local home improvement store representative for assistance.

Q: How long does it take for glued planks to dry?

A: The amount of time it takes for glued planks to dry completely depends on several factors including temperature, humidity levels and the type of adhesive used. In general, expect glued planks to take anywhere from 24 hours up to several days before they are ready for walking on or further installation steps such as trimming or sanding.

What is Floating Installation?

Floating installation is one of the most popular methods used when installing engineered wood flooring in homes today. This type of installation involves placing interlocking boards on top of an underlayment pad without gluing them down. This type of installation provides a great deal of flexibility as well as ease in terms of repairability down the road if needed. However, there are some downs Ides to using a floating installation method, such as increased noise transfer and the potential for planks to shift or move over time.

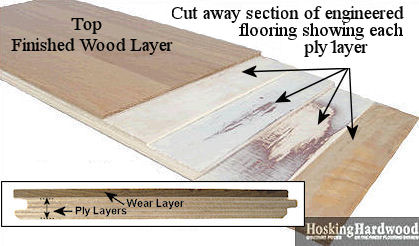

What is the difference between engineered wood flooring and laminate flooring?

Engineered wood flooring is a type of real wood flooring that is made up of multiple layers of plywood or hardwood. The top layer is usually a thin hardwood veneer which provides the look and finish of solid hardwood. Engineered wood flooring can be sanded and refinished over time, making it a durable and long-lasting choice.Laminate flooring is a synthetic product made from layers of melamine resin and fiberboard. It is not real wood, but instead is designed to resemble the look of natural hardwood. Laminate flooring is more affordable than engineered wood, but it cannot be refinished or sanded. Laminate is also more durable and better able to withstand moisture and wear and tear.

What are the advantages and disadvantages of engineered wood flooring?

Advantages:• Engineered wood flooring is extremely durable and can last for decades with proper care.

• It is much more stable than solid wood, meaning it will not warp or expand due to humidity or temperature changes.

• Engineered wood flooring can be installed directly onto concrete, making it a great choice for basements and other areas that solid wood cannot be used.

• It is less expensive than solid wood and can be a great option for budget-conscious homeowners.

• Engineered wood flooring comes in a variety of styles, colors, and textures, so you can find the perfect look for your home.

Disadvantages:

• Engineered wood flooring may not be as strong as solid wood and may not hold up as well to heavy traffic.

• It can be difficult to repair if it is damaged due to its layered construction.

• Some types of engineered wood flooring may fade or discolor over time due to exposure to sunlight.

• It is not as environmentally friendly as some other flooring materials such as cork or bamboo.