Flooring is a great choice to make for the home, commercial business, or perhaps manufacturing sector. If you do not, it's recommended to have an expert do it. They have colored chips or flakes inlaid in the floors and these lend a very decorative and aesthetic experience to the floor. The most effective surface to lay epoxy flooring is concrete, although you are able to put up epoxy flooring over surfaces which include steel and wood as well.

Images about Epoxy Floor Coating Training

This's a solvent based epoxy and once again is thin but comes with an anti-slip grit mixed into it. Epoxy coatings have a recognition for resilience especially with an ability to resist heat of up to 140 degrees Fahrenheit which makes it ideal for thermal exposures. Instead of tearing up the floor and starting all over, or perhaps putting down flooring that won't survive or look healthy for very long, epoxy floor paint is actually a cheaper and simpler method to go.

Flooring Basics – 1-Day Training GarageCoatings.com

Epoxy works as concrete finishes, or top coats that improve the look of industrial floor finishes. This kind of flooring is not hard to put in, and can be achieved by an expert or perhaps a driven do-it-yourselfer by merely following a few simple directions. Many painters find it's not user friendly for these reasons.

Epoxy School – Epoxy Flooring Bronze Card Course

Epoxy flooring provides a complete solution to these problems. Epoxy consists of hardeners as well as resins. It has high resistance to abrasion and chemicals such as alkalis, gasoline, greases, thawing salts, and solvents. For ideal epoxy drying out, air temperature should be between sixty and 90 degrees with the minimum concrete temperature of fifty five degrees F. A bare concrete floor is not so attractive or professional looking.

Get Certified with Hands-On Polished Concrete u0026 Epoxy Training Blog

Epoxy Floor Training Seminar Vaughan

Epoxy Coating Training Course, Xtreme Polishing Systems, Pompano

How to install and epoxy floor coating

Online Epoxy Flooring Course

Floor Coating Business Training Programs and Education Floor Shield

Online Epoxy Flooring Course

Epoxy Coating Classes Epoxy Training Center

Upcoming Training Events for July and August The Epoxy Grind

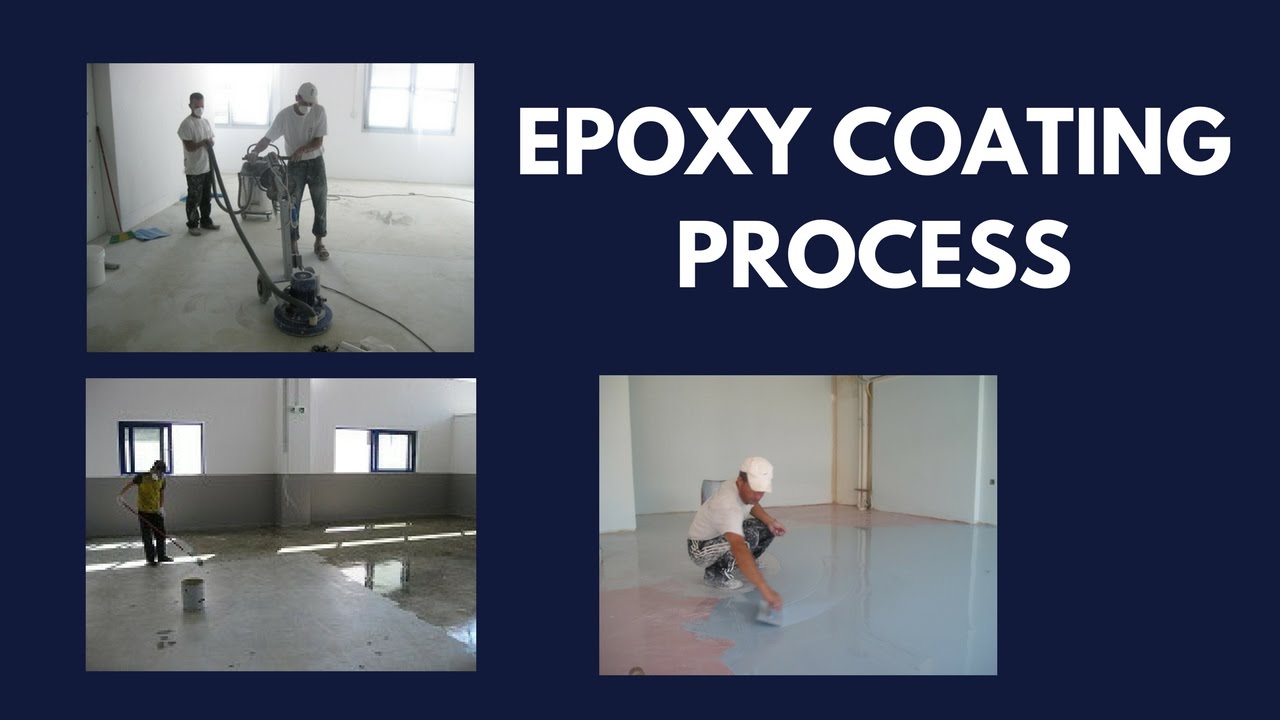

Epoxy Coating Process – The 4 key steps involved (2018)

Epoxy flooring Training Course (2018) – Learn all about our online program

Related Posts:

- How To Remove Epoxy Paint From Concrete Garage Floor

- Epoxy Floors Houston Reviews

- DIY Epoxy Floor Kits

- Rubberized Epoxy Floor Coating

- Epoxy Paint Kit For Garage Floor

- Valspar Garage Floor Epoxy Instructions

- Epoxy Flooring Details

- How To Remove Paint From Epoxy Floor

- 3d Epoxy Floor Designs

- Redo Epoxy Garage Floor

Epoxy Floor Coating Training: The Complete Guide to Gaining Expertise

Epoxy floor coating is a popular choice for many commercial and industrial applications. It provides a durable, low-maintenance, attractive finish that can stand up to high traffic and heavy loads. As such, epoxy floor coating training is essential for anyone involved in the installation of this material. This comprehensive guide provides an overview of the training process, from start to finish, as well as some common FAQs.

What Is Epoxy Floor Coating?

Epoxy floor coating is a type of protective coating made from a combination of epoxy resins and hardeners. The coating is applied in multiple layers to create a durable finish that is resistant to abrasion, chemical spills, and other hazards. The result is a long-lasting surface that looks great and can handle heavy use.

Benefits of Epoxy Floor Coating

Epoxy floor coating offers many benefits over traditional coatings such as paint or sealers. It is highly durable, low maintenance, and resistant to wear and tear. Additionally, epoxy floors are easy to clean and don’t require regular waxing or buffing. Furthermore, epoxy floors are available in a variety of colors and finishes, allowing you to customize your space to meet your needs.

Epoxy Floor Coating Training Overview

The process of epoxy floor coating training begins with an understanding of the materials used in the application process. This includes knowledge about the different types of epoxies available, proper mixing ratios, and application techniques. Additionally, the trainee should be familiar with safety protocols when working with hazardous chemicals and materials such as solvents and strong acids.

The next step in epoxy floor coating training is learning how to properly prepare the substrate (the surface) for application. This involves cleaning the area thoroughly with degreaser and other cleaning agents; repairing any cracks or holes; and priming the surface with an appropriate primer. Once the surface is ready, the trainees will learn how to apply the epoxy layers using a brush or roller in even strokes for optimal coverage. They will also be taught how to mix colors when creating custom designs or patterns on their epoxy floor coatings.

The final step in the epoxy floor coating training process is learning how to properly maintain the coating after it has been installed. This includes periodic cleaning with mild detergent; waxing or buffing on occasion; and drying any spills quickly before they can cause damage to the surface. With proper maintenance, an epoxy floor can last for years without needing major repairs or replacement.

FAQs About Epoxy Floor Coating Training

Q: How long does it take to complete epoxy floor coating training?

A: The length of time required depends on the complexity of the project and experience level of the trainees. However, most projects can be completed within one day with 8-10 hours of total instruction time split between classroom lectures and hands-on practice sessions.

Q: What type of certification do I receive after completing epoxy floor coating training?

A: Upon successful completion of training, you will receive certification from your instructor that demonstrates your knowledge And proficiency in the application of epoxy floor coatings. This certification is often required by employers when hiring for epoxy floor coating professionals.

Q: Are there any safety precautions I should take when working with epoxy floor coatings?

A: Yes, there are several safety measures you should take when applying epoxy floor coatings. You should always wear protective clothing such as gloves, goggles, and a face mask. Additionally, you should avoid inhaling the fumes generated during the application process and properly dispose of any hazardous materials.

What qualifications do I need to become an epoxy floor coating installer?

In order to become an epoxy floor coating installer, you typically need to have at least a high school diploma or equivalent. Some employers may prefer applicants who have experience in construction, mechanical, or other related fields. Additionally, it is often preferred that applicants have basic knowledge of tools and machinery. Some employers may require applicants to be certified in epoxy floor coating installation or have passed some kind of training program.What is the process for becoming an epoxy floor coating installer?

1. Research the Different Types of Epoxy Floor Coating Products: Learn about the different types of epoxy floor coating products, including understanding the differences between solvent-based and water-based epoxies, and how they are applied.2. Obtain Proper Training and Certification: Attend a professional training program to learn how to properly install epoxy floor coatings. Many local painting contractors provide such services. Once you have completed the course, you will need to obtain certification from a reputable industry organization (such as the National Association of Painting Contractors).

3. Purchase Tools and Supplies: Buy or rent the tools and supplies needed for epoxy floor coating installation, such as an airless sprayer, roller frames, paint brushes, drop cloths, stirring sticks, mixing paddles, rags, respirators, goggles and protective clothing.

4. Prepare the Floor: Thoroughly clean the surface you’re working on with a degreaser and power washer. Repair any cracks or chips in the surface with a concrete patching compound. Make sure all surfaces are completely dry before applying any epoxy coating.

5. Apply Epoxy Coating: Carefully read the instructions for your specific product to ensure that you are applying it correctly. Follow all safety precautions while spraying or rolling on the epoxy coatings evenly across the entire surface area. Allow ample time for curing according to product specifications before allowing foot traffic on the surface.