Epoxy floor surfaces are not difficult to clean and are shockingly resistant to bacteria. In past days, epoxies flooring coatings happened to be limited to merchandise retailers, but with the creation of technology, they have turned out to be a trend for flooring needs to have in industries, showrooms, factories, warehouses, garages, hospitals, and federal government facilities brightening up the flooring surfaces.

Images about Epoxy Floor Paint Roller

Once this occurs, there is absolutely nothing you can do to take care of the issue. Regardless of whether there's a bit of wear and tear above your surfacing you can easily fix them with the epoxy floors paints. If the area affected is a compact portion, you do not have to stress with the shade of color. The personalization of epoxy floors doesn't stop for basecoat.

10pcs Cement Self-leveling Kit Epoxy Floor Paint Roller Blade Spike Construction Tool

You will need to get all the measurements and figure simply a little bit bigger than you may possibly have which means you do not run quite short. They are great for restaurants and other food processing business organizations, and are also regularly used in manufacturing ways. Use a covering of epoxy on the spot where by there was the stain.

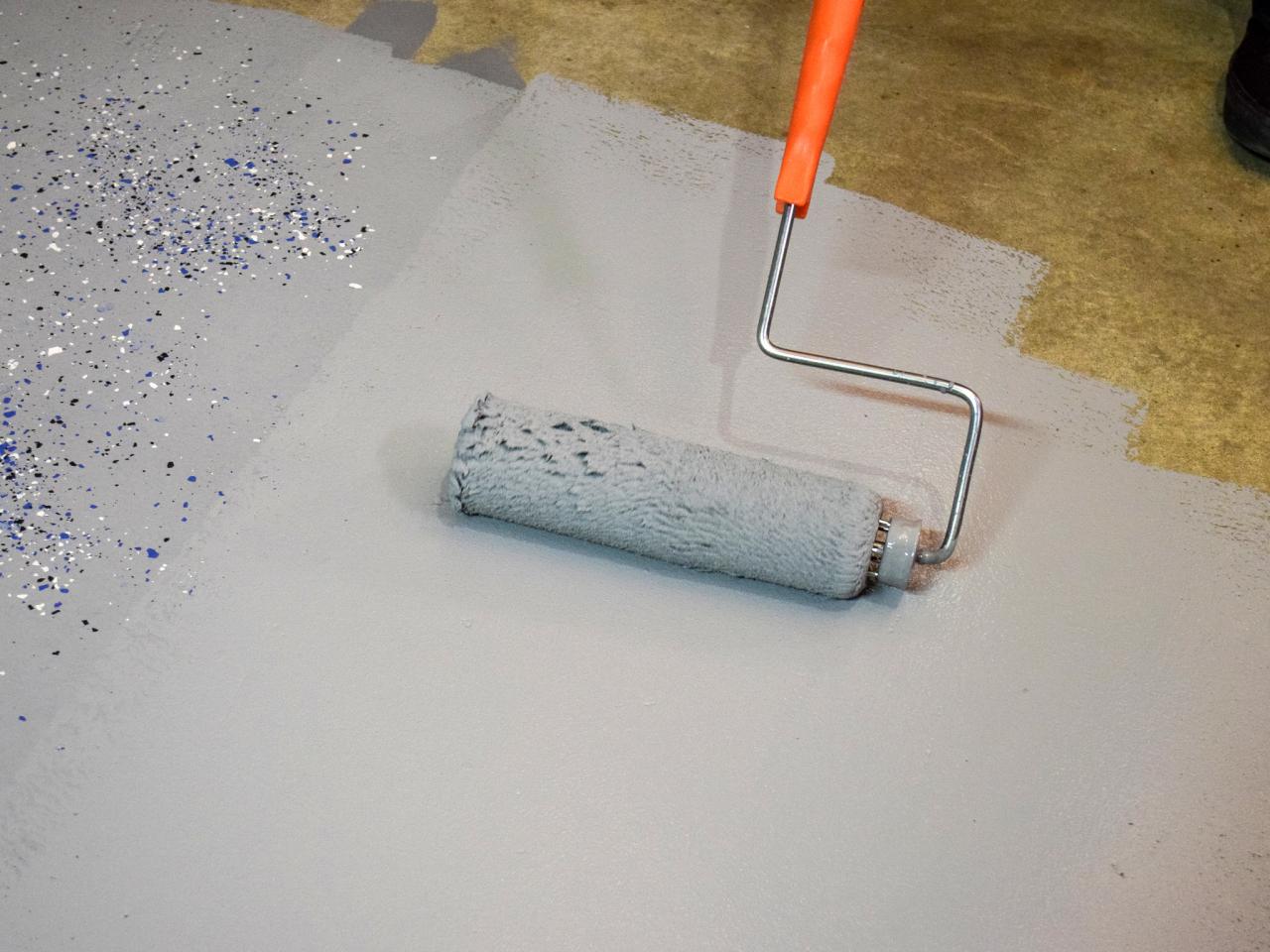

How to Resurface a Garage Floor HGTV

Floor epoxy covering protects your floor from atmospheric pollution, corrosion as well as chemical exposure. On the other hand, the manufacturer's warranty is often more effective and it usually lasts longer compared to the water based counterpart of its.. Epoxy floors are seamless, and there's no place for bacteria as well as other contaminants to multiply. It is equally thermal and impact resistant.

Handy Hints – How to Apply Epoxy Resin Using A Roller

BTMB 23cm/9u0027u0027 Aeration Latex Floor Self Leveling Screed Spiked Roller

Epoxy Spike Roller,Self Levelling Floor Tools,Plastic Spike Roller

9 in. x 1/4 in. Polyester Adhesive and Epoxy Roller RC118-9

Cement Self-leveling Kit Floor Paint Roller Blade Spike Epoxy Tool+

24cm Wall Roller Brush Defoamer for Epoxy Paints DIY

20″ Epoxy Floor Paint Roller Brush With Needle Defoaming Roller

7-inch anti-foaming epoxy floor paint roller brush teeth height 13MM floor paint epoxy corrosion resistant coatings for tools

BEHR PREMIUM 1 gal. Slate Gray Self-Priming 1-Part Epoxy Satin

The Pros and Cons of Epoxy for Concrete Floors – Anderson Painting NC

Pro Construction Tool Cement Self-leveling Kit Epoxy Floor Paint Blade Spike eBay

Related Posts:

- Epoxy Floor Paint Problems

- Epoxy Resin Flooring For Homes

- Epoxy Flooring Installation Instructions

- Epoxy Flooring Advantages Disadvantages

- Self Leveling Epoxy For Concrete Floors

- Epoxy Floor Coating For Showers

- Wood Floor Epoxy Sealer

- Epoxy Resin Garage Floor

- What Is Epoxy Floor Coating

- Epoxy Resin For Shower Floor

Epoxy Floor Paint Roller: The Ultimate Tool for a Smooth and Durable Finish

Introduction:

When it comes to painting your floors, you want a solution that not only looks great but also holds up against wear and tear. This is where epoxy floor paint roller comes into play. In this article, we will explore the benefits of using an epoxy floor paint roller, how to use it effectively, and address some frequently asked questions.

Section 1: Understanding Epoxy Floor Paint Roller

An epoxy floor paint roller is a specialized tool designed specifically for applying epoxy coatings on floors. It consists of a handle, a frame to hold the roller cover, and a refillable tray for the epoxy paint. This tool is essential to achieve a smooth and even application of epoxy paint, ensuring a professional-looking finish.

Section 2: Benefits of Using an Epoxy Floor Paint Roller

2.1 Achieve a Seamless Application

One of the key advantages of using an epoxy floor paint roller is its ability to provide a seamless application. The roller cover evenly distributes the epoxy paint onto the surface, ensuring there are no streaks or uneven areas. This results in a smooth and flawless finish that enhances the overall appearance of your floor.

2.2 Time and Cost-Efficient

Using an epoxy floor paint roller can save you both time and money. Compared to other application methods like brushes or sprayers, rollers cover larger areas in less time, reducing labor costs. Additionally, rollers minimize wastage by efficiently distributing the paint without dripping or splattering.

2.3 Durable and Long-Lasting Finish

Epoxy coatings are renowned for their durability and longevity, and using an epoxy floor paint roller ensures optimal adhesion between the coating and the floor surface. The even distribution of the epoxy paint by the roller creates a strong bond, resulting in a finish that can withstand heavy foot traffic, abrasions, chemicals, and spills.

2.4 Versatility Across Different Floor Types

Whether you have a concrete, wood, or even a tiled floor, an epoxy floor paint roller can be used on various surfaces. Its versatility makes it a practical choice for different environments such as garages, warehouses, commercial spaces, or even residential areas.

Section 3: How to Use an Epoxy Floor Paint Roller Effectively

3.1 Surface Preparation

Before applying epoxy paint with a roller, it is crucial to properly prepare the surface. Start by thoroughly cleaning the floor using a degreaser and removing any existing coatings or loose materials. Repair any cracks or imperfections and ensure the surface is completely dry before proceeding.

3.2 Selecting the Right Roller Cover

Choosing the right roller cover is essential for achieving the desired finish. For epoxy coatings, it is recommended to use a high-quality synthetic fiber roller cover with a nap length appropriate for your specific project. The nap length refers to the thickness of the fibers on the cover and can range from short (1/8 inch) to long (1/2 inch). A shorter nap is suitable for smoother surfaces, while a longer nap is ideal for textured surfaces.

3.3 Mixing and Pouring the Epoxy Paint

Follow the manufacturer’s instructions for mixing the epoxy paint components thoroughly. Once mixed, pour the epoxy paint into a refillable tray designed specifically for epoxy coatings. Avoid pouring too much paint at once to prevent wastage and ensure easier handling during application.

3.4 Applying Epoxy Paint with the Roller To apply the epoxy paint with the roller, start by dipping the roller cover into the tray filled with epoxy paint. Make sure to evenly coat the roller cover with paint, but avoid overloading it to prevent drips.

Begin at one corner of the room and work your way towards the exit, applying the paint in a smooth and even motion. Use long, overlapping strokes to ensure complete coverage and avoid leaving any streaks or uneven areas.

Continue this process until the entire floor is covered with epoxy paint. If necessary, use a brush to reach into corners and edges that the roller may not be able to reach.

Allow the first coat of epoxy paint to dry according to the manufacturer’s instructions. This usually takes several hours or overnight.

Once the first coat is dry, inspect the floor for any missed spots or areas that need touch-ups. Use the same roller and technique to apply a second coat of epoxy paint, if desired. This second coat will provide additional durability and protection.

After applying all coats of epoxy paint, allow the floor to cure completely before allowing foot traffic or placing any heavy objects on it. This curing time can vary depending on the specific epoxy paint used, so refer to the manufacturer’s instructions for guidance.

Overall, using an epoxy floor paint roller is an effective and efficient method for achieving a seamless and durable finish on your floor. By following these steps and taking proper care during application, you can enjoy a long-lasting and visually appealing floor surface.