A printing strategy has been put together to make vinyl flooring are like replicates of fire wood, brick, tile or marble. It is much less per square-metre. You just have to pick the style that best suits your taste, read the make of its, create an order and take them right on the doorstep of yours. What's more, it can be purchased in sheets that resemble stone, other natural textures, slate and tile.

Images about Heat Welded Vinyl Flooring

Regardless of whether you are searching for cheap or luxury vinyl flooring, you have to have at least a little bit of knowledge about vinyl style flooring. In a situation of hours you can totally change the way an area looks simply by putting new vinyl floors in it. Whatever the style of yours or budget preference, you will find options that are many to select from.

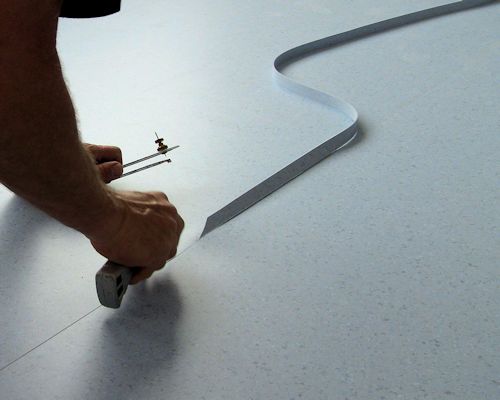

Coventional fit Seams

Vinyl floor tiles don't demand waxing. Instead of wasting your hard earned money on cheap, DIY vinyl which will end up very quickly ruined, have a seasoned install sheet vinyl for your flooring. The moisture may cause the floor to discolor or swell. Not simply is it going to help out with that budget, it'll still maintain the impressive look of a properly chosen floor. It is easy to put in, and also to clean and maintain.

Heat Welding Flooring Seams – Mastering the Fine Art – Floor Consult

How To Cold u0026 Heat Welding PVC (Vinyl) Flooring Vinyl Floor Seam

FLEXCO Rubber Flooring u0026 Vinyl Flooring » Welding Bead Sample Card

What To Keep In Mind When Heat-Welding Sheet Vinyl 2013-01-22

Heat Welding Flooring Seams – Mastering the Fine Art – Floor Consult

Commercial vinyl, General laying techniques, The welding process

Commercial vinyl, General laying techniques, Heat welding equipment

Flash Cove u2014 Preferred Flooring

Choosing the Right Tool: Heat-Welding Flash Coving Under Toe Kicks

How to: Heat Welding Vinyl Floor with Heat Gun,Hot Air Gun

Heat Welding Linoleum – ProInstaller Magazine

Commercial vinyl, General laying techniques, Heat welding equipment

Related Posts:

- Wood Laminate Or Vinyl Flooring

- Installing Peel And Stick Vinyl Flooring

- Vinyl Flooring Manufacturing Companies

- How Much Does Luxury Vinyl Flooring Cost

- 24 X 24 Vinyl Floor Tiles

- Local Vinyl Flooring Stores

- Ivc Us Vinyl Flooring Reviews

- Flexible Vinyl Flooring Looks Like Wood

- Lifeproof Lighthouse Oak Vinyl Flooring

- Where To Buy Coretec Vinyl Flooring

Introduction

Heat welded vinyl flooring is a modern and highly durable type of flooring that provides a great surface for any space. It is made by welding together separate pieces of vinyl flooring material, creating a strong, seamless finish. Heat welded vinyl flooring is an attractive, low-maintenance option that is easy to install and maintain. It is also very resistant to wear and tear, making it suitable for high traffic areas. This article will cover the basics of heat welded vinyl flooring, including its advantages, installation process, and maintenance guidelines.

Advantages of Heat Welded Vinyl Flooring

Heat welded vinyl flooring has several advantages that make it a popular option for many homeowners. One of the biggest benefits of this type of flooring is its durability. The heat welding process creates a strong bond between the pieces of vinyl, making it resistant to wear and tear. This makes it suitable for high-traffic areas without having to worry about it being damaged or scratched over time. Additionally, heat welded vinyl is also easy to clean and maintain. It doesn’t require any special care or cleaning products in order to keep it in good condition.

Another advantage of heat welded vinyl flooring is its appearance. The seams between the pieces are virtually invisible once installed, resulting in a uniform look that can be customized with different colors and textures to suit your taste. Additionally, heat welded vinyl is also more cost-effective than other types of flooring such as hardwood or tile. The material itself is relatively inexpensive and the installation process is relatively simple, making it an economical choice for many homeowners.

Installation Process

The installation process for heat welded vinyl flooring is relatively straightforward and can usually be completed in one day by an experienced installer or contractor. The first step is to prepare the area by ensuring that the subfloor is level and free from debris or irregularities that could affect the installation process. Then, the separate pieces of vinyl are laid out on top of the subfloor and cut to fit the space using a sharp knife or scissors. Once all the pieces are cut to size, they are then connected together using a heat welding machine which melts them together to create a seamless finish. Finally, any remaining seams are filled with sealant and the entire area is cleaned up before allowing people to walk on it again.

Maintenance Guidelines

Heat welded vinyl flooring requires very little maintenance in order to keep it looking its best over time. Regular sweeping or vacuuming will help remove dirt and debris from the surface, while mopping with warm water can be used for deeper cleaning if necessary. Avoid using harsh chemicals or abrasive cleaners as these may damage the surface over time. Additionally, protect your heat welded vinyl floors from heavy furniture or sharp objects as these can cause scratches or dents in the material if not properly taken care of.

FAQs About Heat Welded Vinyl Flooring

Q1: Is heat welded vinyl flooring durable?

A1: Yes, heat welded vinyl flooring is extremely durable due to its strong bonding process created during installation. The seams between each piece are virtually invisible once installed, making it resistant to wear and tear even in high-traffic areas such as hallways or living rooms.

Q2: What is the installation process like?

A2: The installation process for heat welded vinyl flooring is relatively straightforward. The pieces are cut to size and then connected together using a heat welding machine which melts them together to create a seamless finish. Any remaining seams are then filled with sealant and the entire area is cleaned up before allowing people to walk on it again.

What are the advantages of heat welded vinyl flooring?

1. Heat welded vinyl flooring is durable and long lasting, making it a great investment for both residential and commercial applications.2. It is water resistant, making it an ideal choice for wet areas such as bathrooms and kitchens.

3. Heat welded vinyl flooring is easy to clean and maintain, requiring only regular sweeping and mopping.

4. It is highly affordable compared to other types of flooring such as hardwood or laminate, making it a great option for budget-conscious homeowners.

5. Heat welded vinyl flooring comes in a variety of colors, textures, and patterns, allowing you to create your own unique look in any room.

6. It can be installed quickly and easily with minimal disruption to your daily routine.

What are the disadvantages of heat welded vinyl flooring?

1. Heat welded vinyl flooring is more expensive than traditional vinyl flooring.2. Heat welding is a time consuming and labor intensive process and requires specialized tools and training.

3. Heat welded vinyl flooring is more difficult to repair than traditional vinyl flooring.

4. Heat welding can cause the vinyl to become brittle over time, leading to cracks and tears.

5. Heat welded vinyl flooring can be difficult to clean and maintain due to its intricate seams and patterns.