This kind of wood flooring is solid all of the way from top to bottom. Pre-finished flooring is normally more wear resistant because the producer is able to use even more durable coatings in a controlled factory atmosphere. 00 a square foot which will add up to savings that are Considerable depending on the overall dimensions of the room.

Images about Installing Engineered Hardwood Floors On Plywood

And so if you're going for a rustic appearance in the living room of yours or maybe an elegant atmosphere in the dining room of yours, any nearby hardwood experts can help! Many can do historical renovations. Savings that are significant are apparent when installed by the homeowner, reducing overall costs to roughly $2. One can still obtain incomplete hardwoods now.

How To Install Engineered Hardwood Flooring

As well, dust is seen with less difficulty on wood floors than it's on linoleum or even on carpet, particularly in the sunlight and especially if the floor features a dark stain. Since good hardwoods are susceptible to dents & scratches, you have to spend special attention to its species. Homeowners also need to give some thought to that on site finishing will emit noxious VOCs into the home environment.

How to Lay Engineered Wood Floors – This Old House

/cdn.vox-cdn.com/uploads/chorus_asset/file/19494255/wood_floors_toutxlbanner.jpg)

How To Install Click Lock Engineered Hardwood Flooring

Which Method Should I Use to Install My Engineered Wood Floor

Guide: How to Install Engineered Hardwood Floors

How To Lay Engineered Wood Flooring A DIY Guide For Everyone

Which Tools Do You Need to Install Engineered Hardwood Floors

How to Install an Engineered Hardwood Floor

Tips for Installing an Engineered Hardwood Floor

Engineered Hardwood Floor Installation: Part 1

Installing Engineered Hardwood on Concrete – Twenty u0026 Oak

Engineered Hardwood Flooring Installation: Tips and Common

How to install engineered hardwood flooring without professionals

Related Posts:

- Hallmark Hardwood Flooring Reviews

- Floating Hardwood Floor Over Tile

- Is Hickory Hardwood Floor Good

- Walnut Hardwood Flooring Images

- Hardwood Floor Ideas For Bedroom

- Minwax Hardwood Floor Cleaner Directions

- Acacia Hardwood Flooring Durability

- Hardwood Floors To Match Maple Cabinets

- Hardwood Floor Hardness Index

- Cost Hardwood Floors Vs Carpet

Installing Engineered Hardwood Floors on Plywood

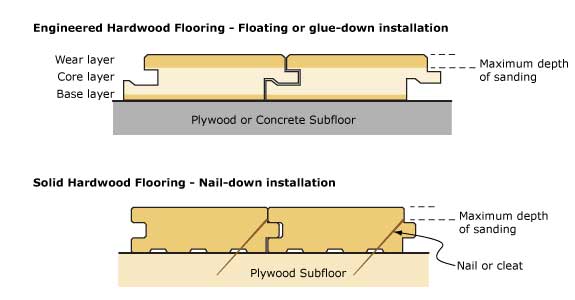

Engineered hardwood is a popular choice for many homeowners due to its durability and ease of installation. It’s also more cost-effective than solid hardwood and offers a variety of design options to choose from. Engineered hardwood can be installed over plywood, which is often found in basements and other areas of the home that may not be suitable for solid hardwood. Installing engineered hardwood floors on plywood is a straightforward process, but there are several important steps that must be taken to ensure that the floor will last for years to come.

Preparing the Subfloor

The first step in installing engineered hardwood floors on plywood is preparing the subfloor. The plywood should be clean and free of any debris, dirt, or oil. It should also be level and free of any gaps or protrusions. If the plywood is warped or uneven, it should be sanded down and leveled using a belt sander or other suitable tools. Additionally, it’s important to make sure that the subfloor is dry and that there are no signs of moisture before proceeding with the installation.

Applying an Underlayment

The next step in installing engineered hardwood floors on plywood is applying an underlayment. This will provide additional cushioning and soundproofing for the floor. It also helps to protect the wood from warping or buckling due to moisture buildup. The underlayment should be applied according to manufacturer’s instructions, which typically requires overlapping seams by at least six inches and taping them together with an adhesive tape.

Installing the Flooring

Once the subfloor has been prepared and the underlayment has been applied, it’s time to install the flooring itself. Engineered hardwood planks come with tongue-and-groove edges that fit together like puzzle pieces, making installation relatively simple. Start by laying out the planks in rows, making sure they are evenly spaced apart and that there are no gaps between them. Secure each plank into place using a hammer and nails or an installation gun. Continue laying out rows until all of the planks have been installed.

Finishing Touches

Once all of the planks have been installed, it’s time to add any finishing touches such as trim pieces or edging strips around the perimeter of the room. These pieces can help give your floor a finished look and help prevent damage from occurring along walls or other edges of the room where furniture may rub against it. Lastly, apply a protective sealant over all of the planks to help protect them from stains and scratches over time.

FAQs

Q: Can I install engineered hardwood floors directly onto plywood?

A: No, engineered hardwood floors must be installed over an appropriate underlayment material before being secured onto plywood subfloors. This helps ensure that your floor will remain level and even over time while providing additional cushioning and soundproofing benefits as well.

Q: What type of adhesive do I need when installing engineered hardwood on plywood?

A: The type of adhesive used will depend on what type Of subfloor you have and what type of engineered hardwood you are installing. It’s best to consult a flooring professional or the manufacturer of your engineered hardwood planks to determine the best type of adhesive for your particular situation.

What type of plywood is best for installing engineered hardwood floors?

Underlayment grade plywood is the best type of plywood for installing engineered hardwood floors. This type of plywood is designed to provide a level, stable surface to support the hardwood flooring. It is also designed to reduce sound transmission and prevent moisture from seeping into the flooring.What type of underlayment should I use with engineered hardwood floors?

Engineered hardwood floors require an underlayment with a built-in moisture barrier. Most engineered hardwood flooring manufacturers recommend using a foam or cork underlayment with a built-in vapor barrier for best results.What is the best material for underlayment for engineered hardwood floors?

The best material for underlayment for engineered hardwood floors is either foam or cork. Foam offers the most cushioning and provides better sound insulation, while cork is more eco-friendly and offers better moisture protection. Both materials are relatively easy to install and can help extend the life of your engineered hardwood floors.</div>

A:

The best material for underlayment for engineered hardwood floors is either foam or cork. Foam offers the most cushioning and provides better sound insulation, while cork is more eco-friendly and offers better moisture protection. Both materials are relatively easy to install and can help extend the life of your engineered hardwood floors. Additionally, engineered hardwood floors should be installed over an appropriate underlayment material before being secured onto plywood subfloors. This helps ensure that your floor will remain level and even over time while providing additional cushioning and soundproofing benefits as well. Lastly, use a high quality adhesive to secure the planks to the subfloor and add trim-pieces or edging strips around the perimeter of the room. These pieces can help give your floor a finished look and help prevent damage from occurring along walls or other edges of the room where furniture may rub against it. Lastly, apply a protective sealant over all of the planks to help protect them from stains and scratches over time.