Because of their benefits, they are thoroughly used on commercial and industrial floors. The coatings also are unstable when subjected to UV rays as well as to temperature changes while in the mixing, software and curing stages. They're robust and in addition have good manual, anti slip properties and good resistance to chemicals. The solid epoxies capably meet up with all of the stringent requirements that are actually to be complied when developing an industrial floor.

Images about Seal Krete Lock Down Epoxy Floor Primer

Several of the basic kinds of epoxy floors offered in the market which are appropriate for manufacturing applications include self dispensing epoxy flooring surfaces, mortar epoxy floors, gravelled epoxy floors, anti-slip and anti-static floors. Flooring is an important part of interior design. Epoxy flooring coatings are very determined by a consistent mix ratio to avoid difficulties during curing time.

Seal-Krete® Lock-Down Clear Concrete Bonding Primer – 1 gal. at

You simply need to hire the epoxy surfacing professionals and tell them of your necessities and demands and they are going to help you have the concrete covering that you demanded. Seamless epoxy flooring will also help reduce the need for floors repairs and at exactly the same time, epoxy flooring offers a stunningly attractive, polished look to your floors.

Have a question about Seal-Krete Lock-Down 1 gal. Epoxy Bonding

Epoxy floors coatings are inexpensive compared with various other floor coatings. While concrete is viewed as virtually indestructible, it is not impervious to particular sorts of damage, including cosmetic, like scuffing, staining and cracking. Nevertheless, if the area affected is actually significant large, color mismatch will be evident. Hence, it's not designed for epoxy coating.

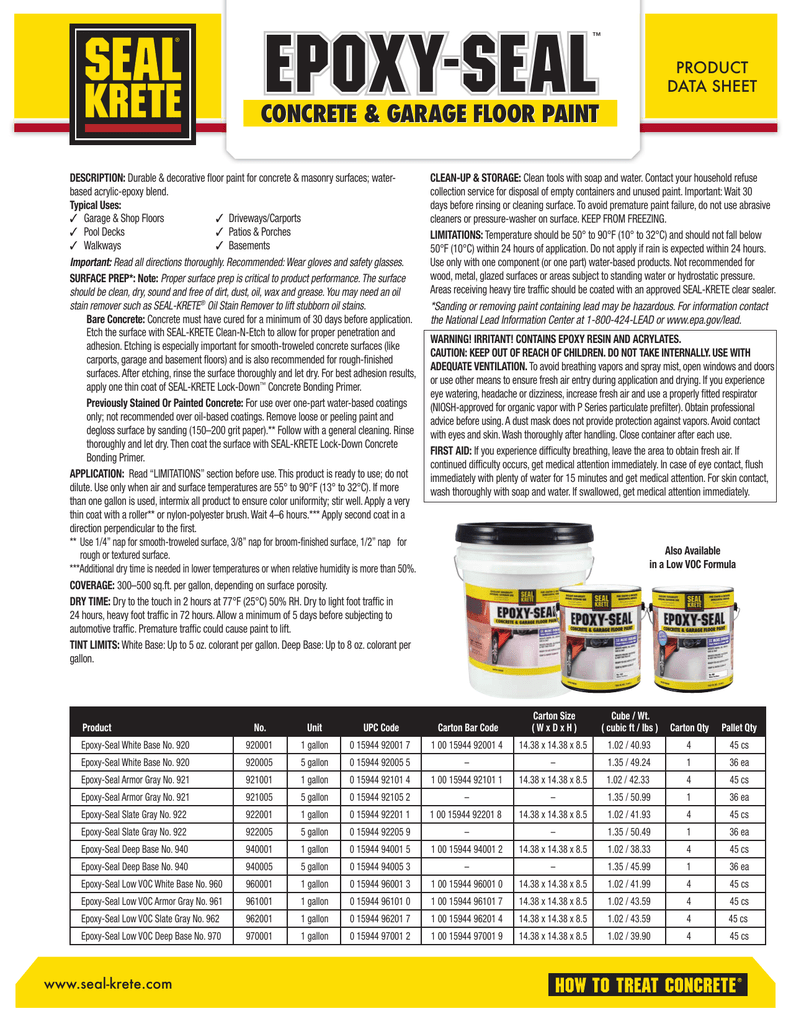

Seal-Krete Epoxy-Seal Low VOC Concrete u0026 Garage Floor Paint, Slate

Seal Krete EPOXY-SEAL Concrete u0026 Garage Floor Paint – GALLON

Seal-Krete 1-part Clear Gloss Concrete and Garage Floor Paint (1-Gallon)

Seal-Krete 106001 Lock-Down 1 gal. Epoxy Bonding Floor Primer Use

Seal-Krete Garage Floor – How To Use Primer

Seal-Krete Epoxy-Seal 1-Part Deep Tintable Satin Garage Floor

Seal-Krete HP – Posts Facebook

SEAL KRETE Lock-Down Concrete Binding Primer Gallon – Walmart.com

epoxy-seal – Seal

Seal Krete 116001 1G Lock-Down Concrete Bonding Primer

Seal-Krete HP – Posts Facebook

Related Posts:

- Epoxy Seal Concrete And Garage Floor Paint

- Epoxy Shield Industrial Floor Coating

- How To Clean Epoxy Coated Garage Floors

- Water Based Epoxy Resin Floor Paint

- Clear Epoxy Resin Floor Coating

- Rustoleum Garage Floor Epoxy Red

- Rhino Linings Epoxy Floor Coating Reviews

- Wattyl Garage Floor Epoxy

- Rustoleum Garage Floor Epoxy Metallic

- Is Epoxy Flooring Slippery

Seal Krete Lock Down Epoxy Floor Primer: A Comprehensive Guide

Introduction:

A well-maintained floor not only enhances the aesthetics of a space but also ensures its durability. Seal Krete Lock Down Epoxy Floor Primer is a highly effective solution for preparing your concrete floors before applying an epoxy coating. In this comprehensive guide, we will delve into the various aspects of Seal Krete Lock Down Epoxy Floor Primer, from its features and benefits to its application process and frequently asked questions.

I. Understanding Seal Krete Lock Down Epoxy Floor Primer:

Seal Krete Lock Down Epoxy Floor Primer is a high-performance primer specifically designed to enhance the adhesion of epoxy coatings to concrete surfaces. It creates a strong bond between the substrate and the coating, ensuring long-lasting protection and durability. This water-based epoxy primer is easy to apply and dries quickly, making it an ideal choice for both residential and commercial applications.

II. Features and Benefits:

a) Superior Adhesion:

One of the key features of Seal Krete Lock Down Epoxy Floor Primer is its exceptional adhesion properties. It penetrates deep into the porous concrete surface, creating a strong bond that prevents peeling or delamination of the epoxy coating. This ensures that your floor remains intact even under heavy foot traffic or vehicular use.

b) Moisture Barrier:

Concrete floors are susceptible to moisture-related issues such as efflorescence and mold growth. Seal Krete Lock Down Epoxy Floor Primer acts as a moisture barrier, preventing water vapor transmission from the substrate to the coating. This feature helps to eliminate common problems associated with moisture, such as blistering or bubbling of the epoxy finish.

c) Chemical Resistance:

In industrial or commercial settings, floors are often exposed to chemical spills or stains. The Seal Krete Lock Down Epoxy Floor Primer offers excellent chemical resistance, protecting your floor from damage caused by acids, oils, solvents, and other harsh chemicals. This ensures that your floor maintains its pristine appearance and durability even in the face of chemical exposure.

d) UV Stability:

Exposure to sunlight can cause discoloration and degradation of epoxy coatings. However, Seal Krete Lock Down Epoxy Floor Primer is formulated with UV stabilizers that provide protection against harmful ultraviolet rays. This feature enhances the longevity and aesthetics of your floor by preventing yellowing or fading over time.

III. Application Process:

a) Surface Preparation:

Before applying Seal Krete Lock Down Epoxy Floor Primer, it is crucial to properly prepare the concrete surface. Ensure that the floor is clean, dry, and free from any contaminants such as oil, grease, or dirt. Use a concrete cleaner or degreaser to remove any stubborn stains or residues. If there are existing coatings or sealers on the floor, they should be mechanically removed or chemically stripped for optimal adhesion.

b) Mixing and Dilution:

Seal Krete Lock Down Epoxy Floor Primer comes in a concentrated form and needs to be mixed with water before application. Follow the manufacturer’s instructions for proper mixing ratios. Typically, a 1:1 ratio of primer to water is recommended for most applications. Use a clean container and mix thoroughly until a homogenous solution is obtained.

c) Application Techniques:

There are multiple ways to apply Seal Krete Lock Down Epoxy Floor Primer, including brush, roller, or airless sprayer. Choose the method that suits your Preferences and the size of the project. For smaller areas or detailed work, a brush may be more suitable, while a roller or sprayer can be used for larger areas to achieve a more even and efficient application. Ensure that the primer is applied evenly and in a thin layer to avoid pooling or uneven drying.

d) Drying and Curing Time:

After applying Seal Krete Lock Down Epoxy Floor Primer, allow sufficient drying and curing time before applying the topcoat or epoxy finish. The exact drying time can vary depending on factors such as temperature, humidity, and ventilation. Typically, the primer will dry to touch within a few hours and fully cure within 24-48 hours. It is important to avoid foot traffic or heavy use during the curing process to ensure optimal performance.

e) Topcoat Application:

Once the primer is fully cured, it is recommended to apply a topcoat or epoxy finish to enhance durability and aesthetics. Follow the manufacturer’s instructions for proper application techniques and mixing ratios of the topcoat. Allow sufficient drying and curing time for the topcoat before subjecting the floor to normal use.

IV. Maintenance:

To maintain the longevity and appearance of your Seal Krete Lock Down Epoxy Floor Primer, regular maintenance is necessary. Here are some maintenance tips:

a) Regular Cleaning:

Regularly clean your epoxy-coated floor using a mild detergent or cleaner specifically designed for epoxy surfaces. Avoid using harsh chemicals or abrasive cleaners that can damage the coating. Sweep or vacuum the floor regularly to remove dirt and debris that can scratch or dull the surface.

b) Spill Cleanup:

Promptly clean up any spills or stains on the floor to prevent permanent damage. Use a soft cloth or mop to absorb and remove liquids, and gently scrub with a non-abrasive cleaner if necessary. Avoid using excessive water or soaking the floor, as this can lead to moisture-related issues.

c) Protection from Heavy Objects:

To prevent scratches or dents caused by heavy furniture or equipment, use protective pads or coasters. Lift heavy objects instead of dragging them across the floor to avoid damaging the epoxy coating.

d) Regular Inspections:

Regularly inspect your epoxy-coated floor for any signs of damage or wear. Address any issues promptly to prevent further deterioration. If necessary, touch up the coating or apply a new topcoat to maintain the integrity of the floor.

By following these guidelines and properly maintaining your Seal Krete Lock Down Epoxy Floor Primer, you can ensure that your floor remains durable, attractive, and resistant to various environmental and chemical challenges.