This option revolves around the facts which epoxy flooring is highly durable, requires minimum maintenance and it is earth friendly. This tends to decrease some wastage and help save you money. The experts understand each and every aspect of the surfacing plus they can use the most up technology for using the epoxy color over the floors of yours.

Images about Esd Epoxy Floor Coating

They are highly-resistant to oil, chemicals, water, and physical impact from pedestrian traffic and mechanical loads. And, in case you've painted floors, the best choice for you is to remove the old paint before making use of any kind of epoxy. Furthermore, the self leveling characteristic of epoxy combination offers an even surface in spite of floors with bumps and cracks.

Anti Static Epoxy Flooring ESD Epoxy Flooring Jemkon

You'll get an extra benefit of protecting your concrete flooring from crude oil stains as well as various other chemical compounds to make a supplementary life to the untreated flooring. Epoxy flooring surfaces are extremely reluctant to surface injury with the inheriting properties of theirs.

Static Control Epoxy Flooring u0026 CRU Coatings Industrial Concrete

Epoxy flooring is a genuine low maintenance choice. Make certain that you understand how to blend it. Apart from that you will find scratch proof and therefore are reluctant to chemical substances, water, grease, dust and other similar chemical agents. Polyurethane and latex floor paints will not work with the latest epoxy floor. Epoxy flooring will give you the profit of not re-doing the floor again and again.

ESD Epoxy Floor Paint – ElectraGuard by United Static Control Products

ESD Epoxy Floors, ESD Epoxy Flooring, Epoxy Floor Coating

ESD Epoxy Flooring ESD Flooring Flooring Widaco

ESD Urethane u0026 Epoxy Coatings StaticWorx GroundSafe ESD Flooring

HB-97.2 ESD Static Conductive Urethane Top Coat Floor Coating Forklift Traffic ANSI/ESD S20.20-2014

ESD floor coatings for electrostatic discharge protection

Static Control (ESD) Epoxy Floor Coating Systems

Introducing our New, vebrostatic ESD Seamless Epoxy Flooring Range

ESD Epoxy Flooring Anti Static Industrial Floors ACTUM

Anti Static Flooring, Epoxy S20.20 certified USA Installation

Poured ESD Epoxy Floors for Anti-static Environments Ground Zero

Related Posts:

- Remove Epoxy Coating From Concrete Floor

- High Build Epoxy Floor Coating

- Benefits Of Epoxy Garage Floor

- Epoxy Polyurethane Flooring Systems

- Epoxy Paint Floor Garage

- How To Clean Epoxy Coated Garage Floors

- Epoxy Garage Floor Coating On Wood

- Black Gloss Epoxy Flooring

- Epoxy Floor Paint Rustoleum

- Best Epoxy Floor Paint For Garage

ESD Epoxy Floor Coating: Ensuring Safety and Protection in Sensitive Environments

Introduction:

In today’s technologically advanced world, electrostatic discharge (ESD) poses a significant threat to sensitive electronic equipment and facilities. To mitigate this risk, industries such as electronics manufacturing, laboratories, cleanrooms, and data centers rely on ESD epoxy floor coatings. These specialized coatings not only provide a durable and visually appealing surface but also offer superior protection against static electricity. In this article, we will delve into the world of ESD epoxy floor coatings, exploring their benefits, applications, installation process, maintenance requirements, and frequently asked questions.

I. Understanding Electrostatic Discharge (ESD)

Electrostatic discharge is the sudden flow of electricity between two objects with different electrical potentials. It occurs when an electric charge accumulates on a person or an object and then discharges upon contact with another object or ground. This phenomenon can cause damage to sensitive electronic components, leading to malfunctions or complete failure.

FAQs:

Q1: What causes electrostatic discharge?

A1: ESD can be generated by various sources such as friction (rubbing of materials together), induction (movement of charged particles), or contact with electrically charged objects.

Q2: How does electrostatic discharge affect electronic devices?

A2: When an electronic device experiences an ESD event, the high voltage surge can disrupt or permanently damage its delicate internal circuitry.

II. The Importance of ESD Control in Sensitive Environments

In environments where electronic devices are manufactured, repaired, or stored, maintaining proper ESD control is crucial. Without adequate precautions in place, the accumulation and release of static electricity can lead to costly consequences like production errors, damaged equipment, or compromised data integrity.

FAQs:

Q1: What are some common industries that require ESD control measures?

A1: Industries that typically require ESD control measures include electronics manufacturing, telecommunications, aerospace, automotive, medical device manufacturing, and laboratories.

Q2: How can ESD control be achieved in these industries?

A2: ESD control is achieved through a combination of measures such as grounding personnel, using antistatic clothing and footwear, employing ionizers to neutralize static charges, and utilizing ESD-safe workstations and furniture.

III. Introducing ESD Epoxy Floor Coating

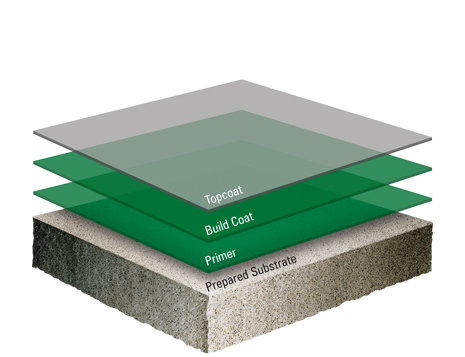

ESD epoxy floor coating is a specialized flooring solution designed to provide an electrostatically dissipative surface in areas where static electricity poses a risk. It consists of a two-part epoxy resin system infused with conductive or dissipative materials that facilitate the controlled dissipation of electrical charges to ground.

IV. Benefits of ESD Epoxy Floor Coating

1. Electrostatic Dissipation:

The primary benefit of ESD epoxy floor coatings is their ability to dissipate static electricity safely. By directing the electrical charges to ground, they prevent the accumulation and subsequent discharge of static energy, effectively protecting sensitive electronic equipment.

2. Enhanced Safety:

ESD epoxy floor coatings also enhance safety by reducing the risk of fire or explosion in environments where flammable substances are present. By preventing static electricity from igniting flammable vapors or dust particles, these coatings play a critical role in maintaining a safe working environment.

3. Chemical Resistance:

ESD epoxy floor coatings offer excellent chemical resistance, making them suitable for environments where exposure to corrosive substances or solvents is common. This resistance ensures the longevity and durability of the flooring system Even in harsh industrial settings.

4. Easy Maintenance:

ESD epoxy floor coatings are easy to clean and maintain. They have a smooth, seamless surface that resists dirt, dust, and stains, making them ideal for environments that require regular cleaning and sanitization.

5. Durability:

ESD epoxy floor coatings are highly durable and can withstand heavy foot traffic, impact, and abrasion. This makes them a long-lasting flooring solution that can withstand the demands of industrial environments.

6. Versatility:

ESD epoxy floor coatings can be customized to meet specific requirements. They come in a variety of colors and finishes, allowing businesses to create a visually appealing and functional flooring system that aligns with their branding and operational needs.

In conclusion, ESD epoxy floor coatings offer numerous benefits for industries that require ESD control measures. From protecting sensitive electronic equipment to enhancing safety and durability, these specialized flooring solutions are an essential component of maintaining a controlled static-free environment.