Polished concrete floors are extremely light green. When looking to decorate your own home or perhaps work place with a distinct and long lasting color effect, look no further than acid stain concrete flooring to bring brightness and life to your floors and rooms. But in today's world of decorating natural materials for flooring in countertops are much sought after in a single of the huge trends is actually decorative concrete.

Images about Refurbishing Concrete Floors

Damp polishing creates waste slurry which easily transfers into hard-to-find tough to reach locations. On a brand new concrete, stain concrete floors making companies advise letting the concrete solution for no less than a month. In addition to making polished concrete incredibly renewable, concrete has long been the most inexpensive flooring choice offered.

Refinishing Options for Older Concrete Floors

A number of benefits of polished concrete flooring are the long life of its, in addition to the practically limitless style alternatives available. Concrete flooring is excellent for warm climates since it stays cool even in the hottest weather conditions. If you are preparing the floor of your office or house to be concreted, you will find a few things you have to check.

Refinishing Concrete Floors Life of an Architect

Before and after transformations of industrial polished concrete

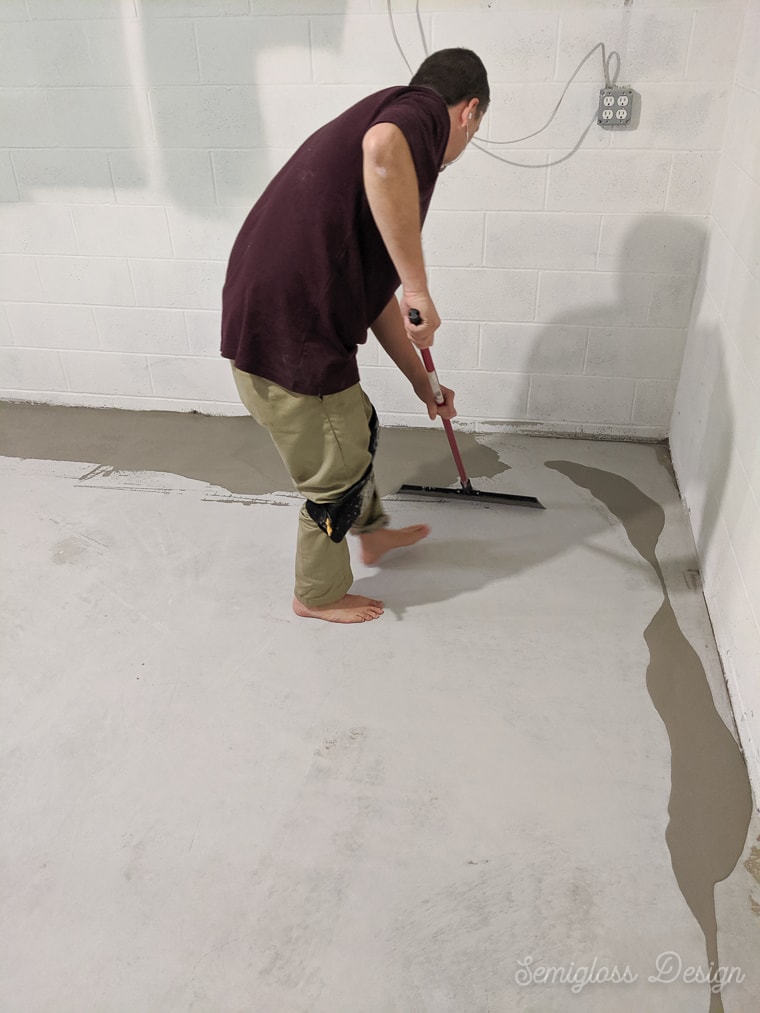

How to Refinish Concrete Floors in a Basement – Semigloss Design

Concrete Floor Resurfacing vs. Polishing

Concrete u0026 Epoxy Floor Resurfacing/Polishing Company VA

Refinishing Concrete Floors Life of an Architect

MS Floor Refinishing – Tile Refinishing – WWe Refinish Concrete

How to easily resurface a concrete floor Watco – YouTube

Concrete Floor Refinishing- 100% solid Epoxy application before

Concrete Resurfacing – The Caretakers, Inc.

Fixing Concrete Floors u2013 How to Fix Concrete Floors – Concrete Network

How to Refinish Concrete Floors in a Basement – Semigloss Design

Related Posts:

- Concrete Floor Remodel

- Concrete Floor Waterproofing Paint On

- Concrete Floor Paint Water Based

- Epoxy Paint For Concrete Floors Sherwin Williams

- Concrete Floor Acid Stain Cost

- How To Lay Concrete Floor Slab

- Concrete Floor Screed

- Concrete Floor Sealers Best

- How To Get Polished Concrete Floor

- Easy Concrete Floor Ideas

Refurbishing Concrete Floors: Bringing New Life to Old Surfaces

Introduction:

Concrete floors are known for their durability and longevity. However, over time, they can develop wear and tear, become stained, or lose their luster. Refurbishing concrete floors is an excellent way to breathe new life into these surfaces, restoring their appearance and enhancing their functionality. In this article, we will delve into the process of refurbishing concrete floors, exploring various methods, materials, and techniques to help you achieve stunning results.

I. Assessing the Condition of the Concrete Floor:

Before embarking on any refurbishment project, it is crucial to assess the condition of the concrete floor thoroughly. This assessment will help determine the extent of repair required and guide your choice of refurbishment method.

a) Conducting a Visual Inspection:

Begin by conducting a visual inspection of the concrete floor. Look out for cracks, chips, stains, or other signs of damage that may need attention during the refurbishment process. Note down any areas that require repair or restoration.

FAQs:

Q1: How can I identify cracks in my concrete floor?

A1: Cracks in concrete floors are often visible to the naked eye. They can be hairline cracks or larger fractures that extend across the surface. Additionally, you may notice unevenness or sinking in specific areas, indicating underlying issues.

Q2: What causes stains on concrete floors?

A2: Stains on concrete floors can result from spills such as oil, grease, or food substances. Rust from metal objects or chemicals can also cause discoloration.

II. Repairing Cracks and Defects:

Once you have identified cracks or defects on your concrete floor, it is essential to address them before proceeding with any refurbishment work. Repairing these issues will ensure a smooth and durable finished surface.

a) Filling and Sealing Cracks:

For smaller cracks, use a concrete crack filler or epoxy adhesive to fill the gaps. Apply the filler using a putty knife, ensuring it reaches all the way down to the base of the crack. Smooth out the surface and allow it to cure according to the manufacturer’s instructions.

For larger cracks, consider using a concrete patching compound. Clean the crack thoroughly, removing any loose debris or dirt. Moisten the crack with water and apply the patching compound, following the manufacturer’s instructions. Smooth out the surface and allow it to dry completely before proceeding.

FAQs:

Q1: Can I use regular cement to fill cracks in my concrete floor?

A1: Regular cement is not recommended for filling cracks as it lacks flexibility and may not adhere well. It is best to use specialized concrete crack fillers or patching compounds designed for this purpose.

Q2: How long does it take for epoxy adhesive to cure?

A2: The curing time for epoxy adhesive can vary depending on factors such as temperature and humidity. Generally, it takes around 24 hours for epoxy adhesive to fully cure.

III. Surface Preparation:

To achieve optimal results when refurbishing your concrete floor, proper surface preparation is crucial. This step involves cleaning, degreasing, and ensuring a smooth substrate for subsequent treatments.

a) Cleaning the Concrete Surface:

Start by thoroughly cleaning the concrete floor using a suitable cleaner or degreaser. Remove any dirt, dust, oil, or other contaminants that may hinder proper adhesion of coatings or treatments. Scrub the surface with a stiff brush or use a pressure washer for more Stubborn stains or dirt. Rinse the floor thoroughly and allow it to dry completely before proceeding.

b) Repairing Surface Defects:

Inspect the surface for any defects such as chipped or spalled areas. Use a concrete patching compound to fill in these areas, following the manufacturer’s instructions. Smooth out the surface and allow it to dry completely before moving on.

c) Grinding or Etching:

If the concrete floor has a smooth finish or a previous coating, it may be necessary to roughen the surface for better adhesion. This can be done through grinding or etching methods. Grinding involves using a concrete grinder with abrasive discs to remove the top layer of the concrete, creating a rough texture. Etching involves applying an acid solution to the surface to chemically remove a thin layer of the concrete.

FAQs:

Q1: Can I use muriatic acid for etching my concrete floor?

A1: Muriatic acid is commonly used for etching concrete, but it is important to handle it with caution as it is highly corrosive. Follow safety guidelines and instructions provided by the manufacturer when using muriatic acid.

Q2: Do I need special equipment for grinding my concrete floor?

A2: Yes, you will need a concrete grinder equipped with abrasive discs for grinding your concrete floor. These machines are typically available for rent at hardware stores or equipment rental companies.

IV. Applying Coatings and Finishes:

After completing the necessary repairs and surface preparation, you can proceed with applying coatings and finishes to enhance the appearance and durability of your concrete floor.

a) Priming the Surface:

Before applying any coatings, it is recommended to apply a primer to ensure proper adhesion and improve the longevity of the finish. Choose a primer specifically designed for concrete surfaces and follow the manufacturer’s instructions for application.

b) Applying Coatings:

There are various types of coatings available for concrete floors, such as epoxy, polyurethane, or acrylic. Choose a coating that suits your desired aesthetics and functional requirements. Follow the manufacturer’s instructions for application, including mixing ratios and drying times.

c) Finishing Touches:

Once the coating is applied, you can add additional decorative elements or finishes if desired. This can include staining, stamping, or sealing the surface. Follow the specific instructions for each finishing technique to achieve the desired result.

FAQs:

Q1: How long does it take for a concrete floor coating to dry?

A1: Drying times for concrete floor coatings can vary depending on factors such as temperature and humidity. It is best to refer to the manufacturer’s instructions for specific drying times.

Q2: Can I apply a second coat of coating on my concrete floor?

A2: Yes, in some cases, applying a second coat of coating can provide additional protection and durability. However, it is important to follow the manufacturer’s instructions regarding recoat times and application methods.